What are the advantages of cable tray roll forming machine?

2025-01-18 14:45Definition of Cable Tray making machine

Cable tray is an important structure used to support insulated cables for power distribution, control and communication. As a highly efficient alternative to open wiring or electrical conduit systems, cable trays provide safe, secure pathways for cables in a variety of environments.

They are particularly useful for running large amounts of data cables overhead or under the floor and are often referred to as baskets, trunking or cable ladders. It is widely used in industry, commercial buildings and infrastructure projects, providing a simple, flexible and economical solution for cable wiring.

The production of cable trays requires efficient and precise equipment support. The cable tray roll forming machine launched by KINGREAL is designed to meet the diverse production needs of customers and is capable of producing cable tray systems of various sizes and types. Its high-speed production and consistent quality advantages provide customers with significant competitiveness.

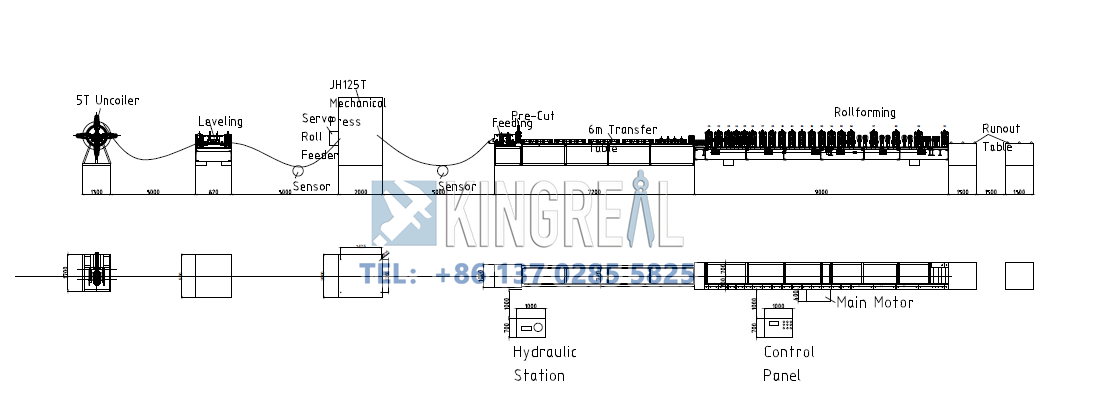

Main components of cable tray making machine

- Decoiler

- Precision Straightener

- Punching Machine

- Main Roll Forming Machine

- Cut to Length Machine

Workflow of Cable Tray Making Machine

Uncoiling - leveling - punching - forming - cutting - unloading

Parameter of cable tray roll forming machine

Material | Galvanized,Steel,Iron,HR coils |

Raw Material Thickness | 0.8 - 2.0mm |

Input Material Width | As Profile Request |

Working Speed | 10m/min |

Features of KINGREAL cable tray roll forming machine

1. Adapt to a variety of metal raw materials

KINGREAL cable tray roll forming machines are able to process metal raw materials with a thickness range of 0.8mm to 2.0mm, covering most cable tray production needs. Whether it is steel, stainless steel or galvanized material, this equipment can process it efficiently and ensure the quality of the finished product.

2. High-speed production capability

The equipment's production speed can reach up to 10 m/min, which significantly improves production efficiency and can meet customers' needs for mass production. High-speed production not only shortens delivery cycles, but also helps customers reduce production costs.

3. Flexible size adjustment

KINGREAL cable tray making machine can support processing cable trays of various sizes on one production line by adjusting the roller set.

- Quick adjustment: When changing specifications, there is no need to significantly change the equipment settings, saving adjustment time.

- Diversified production: Customers can flexibly produce cable trays of different specifications according to market demand, enhancing the diversity of product lines.

4. Intelligent operating system

KINGREAL cable tray roll forming machine is equipped with an advanced intelligent operating system, supporting both manual and automatic operation modes:

- Fully automated production: One-click operation enables fully automated production from raw materials to finished products, reducing manual intervention and improving production efficiency.

- Manual assisted operation: When personalized adjustments are required, operators can manually control the production process and flexibly respond to special production needs.

- Whole-line monitoring and fault detection: The equipment is equipped with real-time monitoring function and fault detection system to ensure safe and efficient production process.

- Precise cutting: The control panel can calculate the total length of the finished coil and display the product length and automatically complete the precise cutting through encoder signal feedback.

5. Continuous Operation Capability

The hydraulic system of the equipment is equipped with an efficient cooling system, which can support long-term operation of the cable tray making machine and can work continuously for up to 20 hours per day.

- Reliability: The cooling system effectively reduces the risk of overheating of the hydraulic system due to long-term operation, ensuring stable operation of the equipment.

- Large-scale production guarantee: Provide customers with long-term and efficient production capabilities, suitable for the delivery needs of large-volume orders.