How is strut channel made?

2025-01-15 12:131. Introduction of strut channel

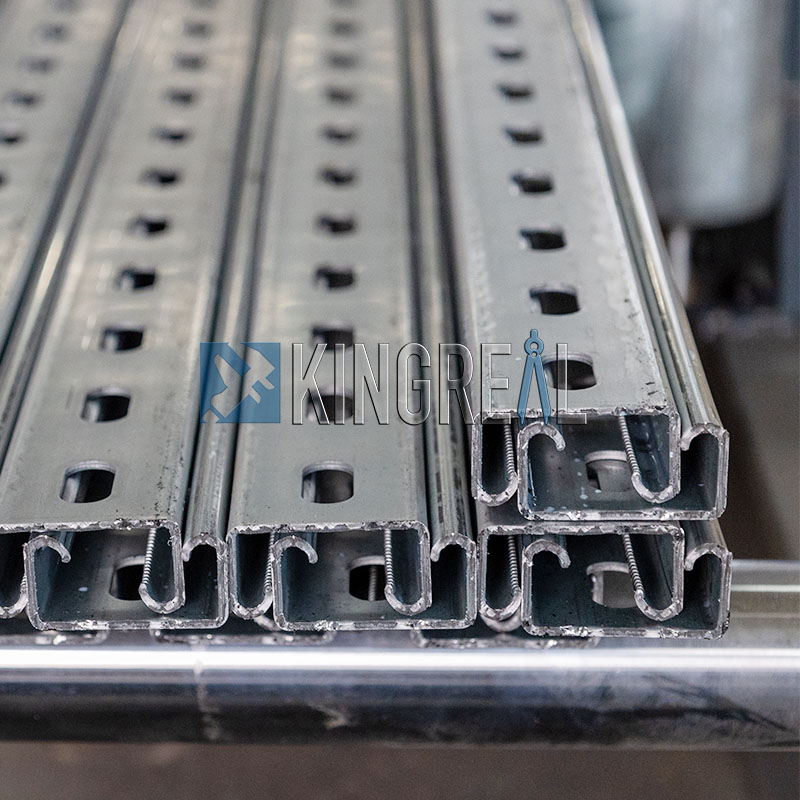

Photovoltaic brackets are structural devices used to install and support solar photovoltaic modules, ensuring that solar panels can be firmly fixed in the predetermined position after installation and receive sunlight at a reasonable angle, so as to achieve the best photovoltaic power generation efficiency. Photovoltaic brackets are usually made of metal materials (such as aluminum alloy, carbon steel and stainless steel, etc.) or other weather-resistant materials.

They have strong wind pressure resistance and corrosion resistance and can withstand long-term use in harsh environments. They are characterized by no welding, no drilling, 100% adjustable and 100% reusable. Among then, these strut channels are made by pv bracket roll forming machine.

2. From Components to Processes: Strut Channel Roll Forming Machine

2.1Main components of pv bracket roll forming machine

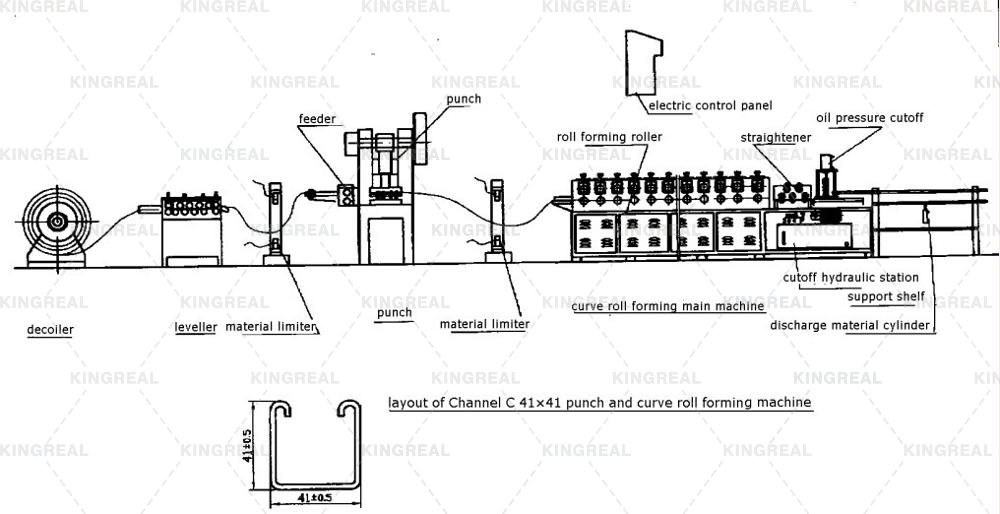

Photovoltaic bracket forming machine is mainly composed of uncoiling machine, leveling machine, punching machine punching equipment, forming machine, hydraulic shear, receiving table, electrical system, baler and other precision components

2-in-1 Decoiler & Straightener

This integrated system combines both decoiler and leveler into a single unit, reducing installation space and minimizing the intermediate step in the metal material straightening process.

Punching Machine

Punching can accommodate all hole sizes specified in the drawing. If you have special requirements for the hole shape, please send the drawing to KINGREAL.

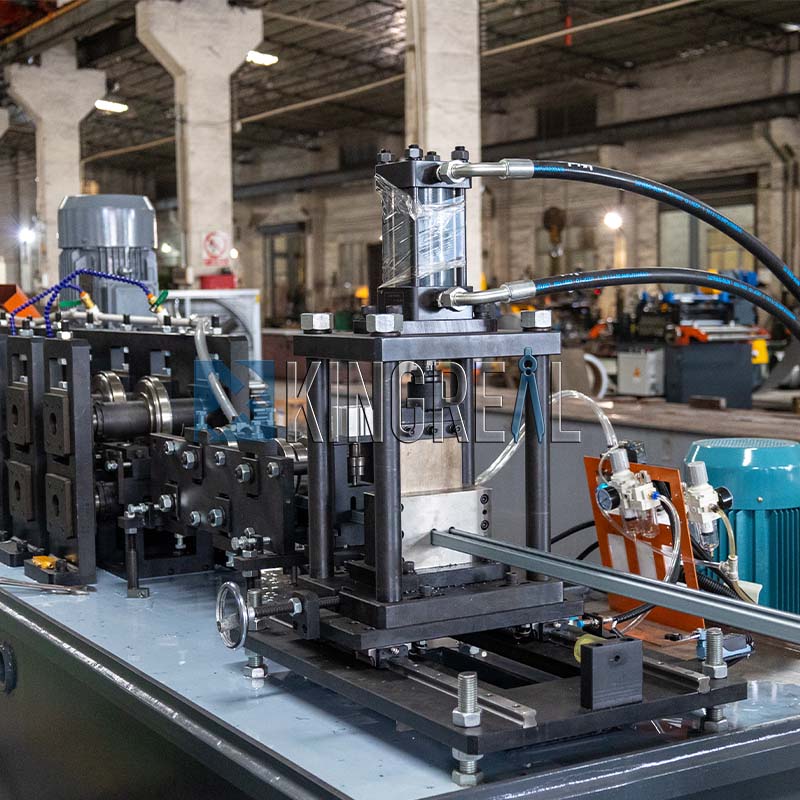

Main Roll Forming Machine

The production requirements of brackets with different specifications can be met by manually adjusting or changing several sets of rollers.

Shearing System

The hydraulic shear system maximizes production speed without stopping the photovoltaic bracket forming machine during shearing.

Auto Package Unit

Automatic packaging machines reduce dependence on manpower and can solve the packaging of finished products more efficiently and intelligently.

2.2 Working Flow of pv bracket roll forming machine

Uncoiling - leveling - punching - forming - cutting - unloading - packaging

3. KINGREAL strut channel roll forming machine

① Dual-Product Capability

One production line is capable of producing two different-sized finished products. The KINGREAL strut channel roll forming machine can fulfill customers' requirements for strut channel of various specifications (41x41mm and 41x21mm) through manual adjustments or roller replacements.

② Variable Speed Control

The KINGREAL pv bracket roll forming machine offers a maximum forming speed of 10-15 m/min. Customers can adjust the machine's speed based on actual production requirements to suit different operational needs.

③ Tailored Solutions

The KINGREAL strut channel roll forming machine is versatile, capable of producing 41×21mm, 41×41mm, 41×62mm, and 41×82mm strut channels. For customers with specific size and thickness needs, simply provide the drawing to KINGREAL, and our engineers will customize a strut channel roll forming machine to meet those requirements.