What Is The Application Of Aluminium Linear Strip Ceiling?

2024-09-18 19:40With the development of society, the use of aluminium linear strip ceiling decorative materials are more and more widely, in many places can see the figure of linear ceiling panels. Aluminium linear ceiling is also a kind of decorative materials which is popular. In order to let everyone know more about different metal ceilings, so as to choose the right one, today KINGREAL will introduce aluminum linear ceiling and linear strip ceiling machine.

Application of linear strip ceiling

1. Gas station

Gas stations or toll stations generally use windproof aluminium linear strip panel, that is, S300 windproof aluminium linear panels. The material of aluminium linear ceiling panel is made of aluminium alloy, the main reason for using windproof aluminium linear strip ceiling panel in gas stations is anti-corrosion and fire prevention, and there is also a special windproof buckle structure. With strong windproof ability, the windproof bar buckles can be widely used in gas stations, gymnasiums, aisles, and other places with high wind pressure.

2. Metro station

Aluminium linear strip ceiling is also suitable for metro station, airport and station. These places often use the C-shape aluminium suspended linear strip ceiling. C-shape aluminium suspended linear strip ceiling is a closed type of aluminium linear strip ceiling panel, the plate surface is neat, have a beautiful appearance and a variety of colours, very suitable for these places.

3. Lobby

Traditional office building lobbies usually use gypsum board, which is not beautiful or neat, and the later maintenance costs are higher. Nowadays, G-shaped aluminum linear ceiling panels are often used in office building lobbies. The G-shape aluminum strip linear ceiling panel is characterized by its unique shape and neat appearance, which can make the office environment more beautiful.

4. Home decoration

Interior ceiling decoration generally use square metal ceiling. If you want to try a different home decoration style, you can consider the H-shaped aluminum linear ceiling, which is more fashionable. It is characterized by neatness and elegance, and the price is also very affordable and cost-effective. No matter you favor square metal ceiling or H-shaped aluminum linear strip ceiling, KINGREAL both have a solution. Our professional linear strip ceiling production machine make your ceiling production more easily.

How are linear strip ceilings produced?

1. Preparation of metal coils

The first step in strip ceiling production is to put metal coils into the linear strip ceiling machine. These coils are usually made of aluminum or galvanized steel, with good strength and corrosion resistance, suitable for construction and decoration. The choice of metal coils directly affects the quality and performance of the strip buckles, so it is crucial to choose high-quality raw materials.

2. Uncoiling

At the decoiler of the linear strip ceiling machine, the metal coils are unrolled and fixed to the production equipment. The decoiler ensures the flatness of the coils, which facilitates the subsequent process. This link is a very critical step in the production process. Any uneven uncoiling may cause defects in subsequent forming.

3. Leveling

After uncoiling, the coil enters the leveling machine. The leveler adjusts the corrugation and bends of the metal coil to a flat state through a specific mechanical structure to ensure that it can be evenly stressed during the forming process. This step is crucial to improving the quality and consistency of the strip buckles.

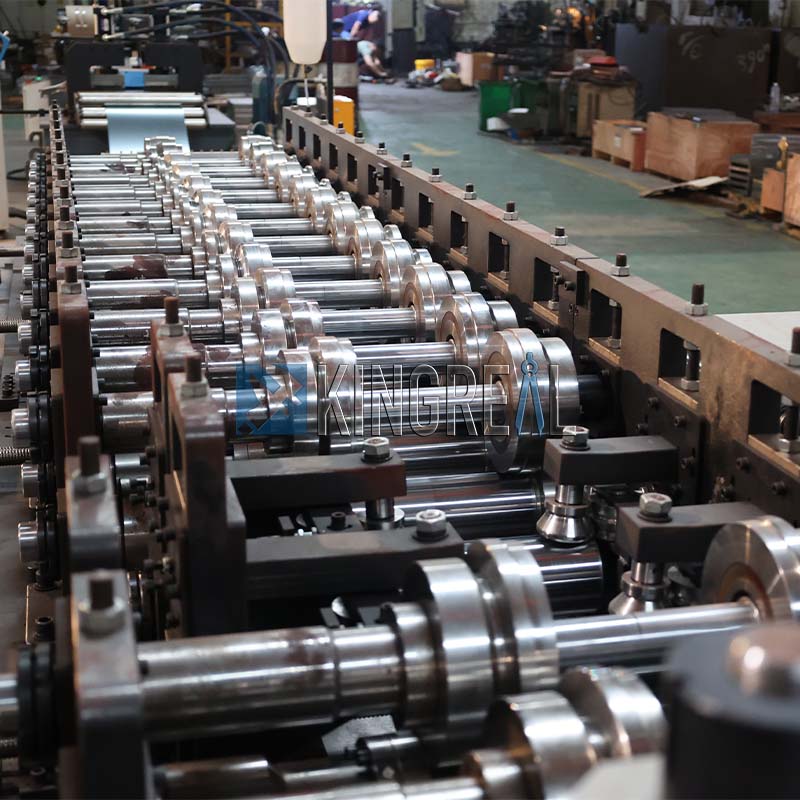

4. Forming

The flattened metal coils enter the roll forming machine. During this process, the metal material is pressed into the desired linear strip ceiling shape. The mold design of the roll forming machine is customized according to customer needs, and can produce linear strip ceilings of different shapes and sizes, such as C-type, G-type, H-type, U-type and V-type. The precision of the forming process is directly related to the appearance and structural strength of the linear strip ceiling, so the use of high-precision molds is the key to ensure product quality.

5. Punching (optional)

During the linear strip ceiling production process, KINGREAL can also equip the linear strip ceiling machine with a punching station. This option allows the buckle to be punched directly during production to meet customer needs for perforated linear strip ceiling. The punching station can punch holes while forming, improve production efficiency, and ensure the accuracy of the punching position.

6. Cutting

After forming, the linear strip ceiling will enter the cutting station. Here, the linear strip ceiling is cut according to the specific requirements of the customer to ensure that the length of each strip ceiling meets the specifications. The cutting station has a very high precision, which can ensure that the edges of the cut linear strip ceiling are smooth and burr-free, which is convenient for subsequent installation and use.

7. Inspection and Packaging

Finally, the produced linear strip ceilings undergo a strict quality inspection, including appearance, size and strength, to ensure that each product meets the standards. Qualified linear strip ceilings will be packaged and ready to be shipped to customers.

Advantages Of KINGREAL Linear Strip Ceiling Machine

As a linear strip ceiling machine manufacturer with more than two decades of experience, KINGREAL provides a range of efficient linear strip ceiling machines with its advanced technology and quality service. The advantages of the KINGREAL linear strip ceiling production line will be discussed in detail below.

Multi-specification production capacity

A significant advantage of the KINGREAL linear strip ceiling production line is its ability to produce linear strip ceilings of different sizes. In order to meet the diverse needs of the market for strip ceilings, KINGREAL has specially designed a multi-specification linear strip ceiling production line. With simple roller adjustments, users can produce strip ceilings of multiple sizes on the same line. This flexibility makes the production process more efficient, reduces the idle time of the equipment, and also reduces production costs. Whether it is a small residential or large commercial building, KINGREAL's linear strip ceiling machine can meet the different needs of customers.

Precision punching technology

As market demand changes, the design of the linear strip ceiling is also evolving. KINGREAL has successfully responded to this market trend by equipping the linear strip ceiling machine with a punching station. The introduction of the punching station makes the strip ceiling not only beautiful in appearance, but also improved in practicality. Through precise punching technology, the strip ceiling can achieve high-precision hole design, which is convenient for installation and subsequent embedding of facilities such as lamps and ventilation systems. This improvement not only increases the added value of the product, but also enhances the customer's experience.

Complete production solution

KINGREAL's linear strip ceiling machine not only focuses on the production of strip ceilings, but can also be used in conjunction with the linear strip ceiling carrier production line to form a complete production solution. The perfect combination of strip ceilings and strip ceiling carriers can ensure the stability and safety of the ceiling. Through this systematic production method, customers can get all the accessories they need at one time, thereby reducing the complexity and cost of the procurement process. At the same time, this integrated solution also improves construction efficiency, allowing construction projects to proceed more smoothly.

Video About Linear Strip Ceiling Machine

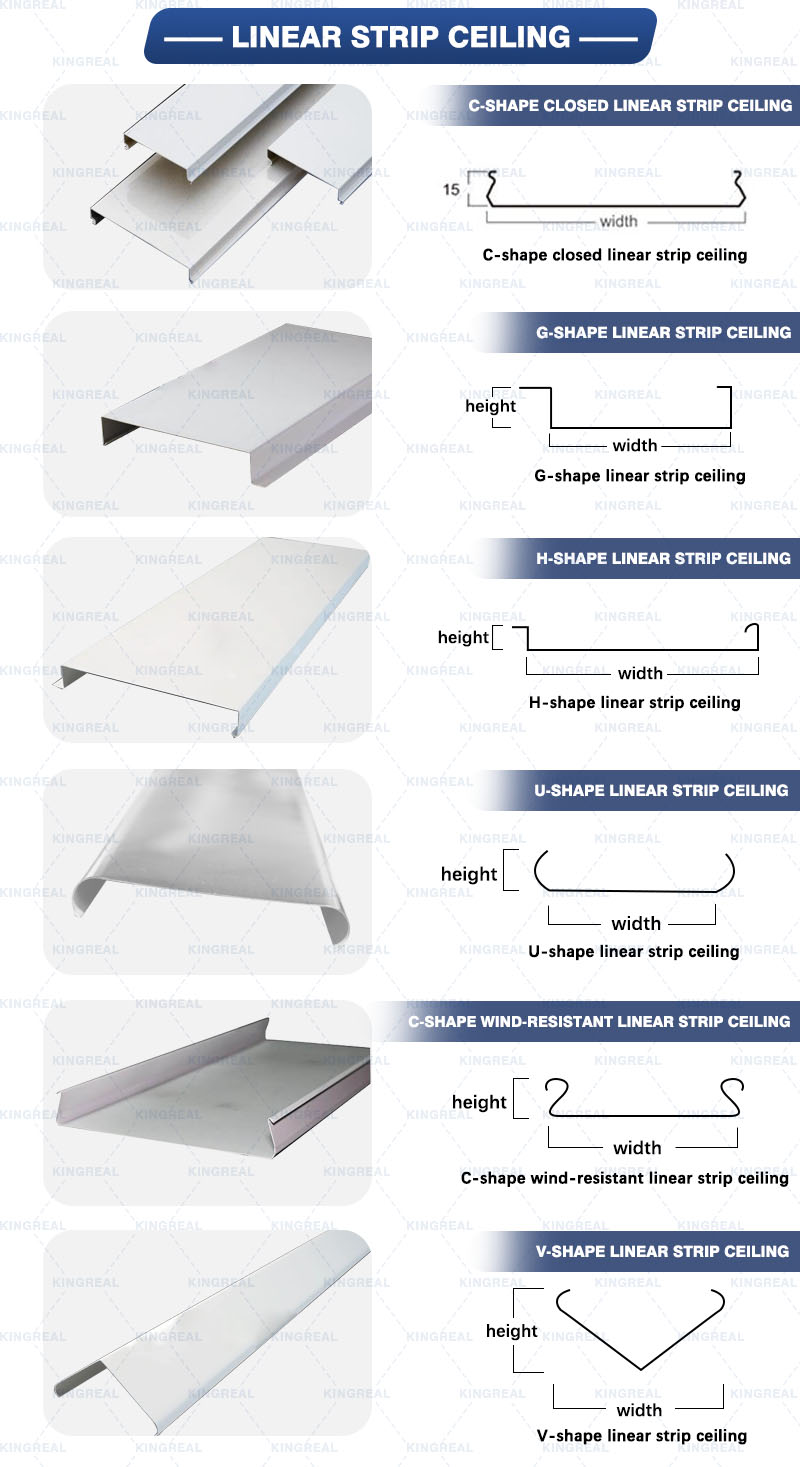

Different types of linear strip ceilings

KINGREAL can provide customers with a variety of linear strip ceiling machine manufacturing solutions, capable of producing different types and sizes of linear strip ceilings. Here are some of the main types of strip ceilings:

- C-type strip ceilings: suitable for the structure of suspended ceilings and partitions, with good load-bearing capacity.

- G-type strip ceilings: commonly used for ceiling installation, can be well combined with other components.

- H-type strip ceilings: suitable for occasions requiring higher strength and load-bearing, widely used in large-scale construction projects.

- U-type strip ceilings: usually used for decoration and beauty, suitable for ceiling design of home and commercial spaces.

- V-type strip ceilings: with unique shape, often used for special decoration needs.

In addition, KINGREAL's linear strip ceiling machines can also be customized according to the specific needs of customers to ensure that the diverse needs of different markets are met.