What is the purpose of the furring channel?

2024-12-09 18:36As a common building material in the field of construction and decoration, furring channel plays an important role in ceiling and partition systems. Its unique hat-shaped design not only improves installation efficiency, but also significantly enhances the stability and aesthetics of the structure. In addition, compared with L-shaped channel and U-shaped channel, hat-shaped channel has unique functions and advantages in different application scenarios.

In the production process of hat-shaped channels, the ceiling channel machine is indispensable as the core equipment. This article will discuss the main function of the hat-shaped channel, combined with the characteristics of L-shaped and U-shaped channels, to gain an in-depth understanding of the importance of the channel ceiling machine in the production process.

The main function of hat-shaped channel

1. Provide structural support

The main function of the hat-shaped channel is to provide reliable structural support for the suspended ceiling or wall. Due to its unique hat-shaped design, it has high strength and load-bearing capacity, which can effectively disperse the ceiling load and avoid local deformation.

2. Achieve flat surface installation

During the renovation process, hat-shaped channels are usually used to fix decorative panels, such as gypsum board or other lightweight materials, to ensure that the surface after installation is smooth and seamless.

3. Absorb building vibration and reduce noise

Through its elasticity and unique design, hat-shaped channels help absorb building vibrations and reduce noise transmission, thereby improving building comfort.

4. Adapt to a variety of building needs

Hat-shaped channels can be used in a variety of scenarios, such as home decoration, ceiling systems in commercial buildings, partition walls, and soundproof walls in audio rooms, etc., and have high flexibility.

Characteristics and uses of L-shaped channels and U-shaped channels

L-shaped channel

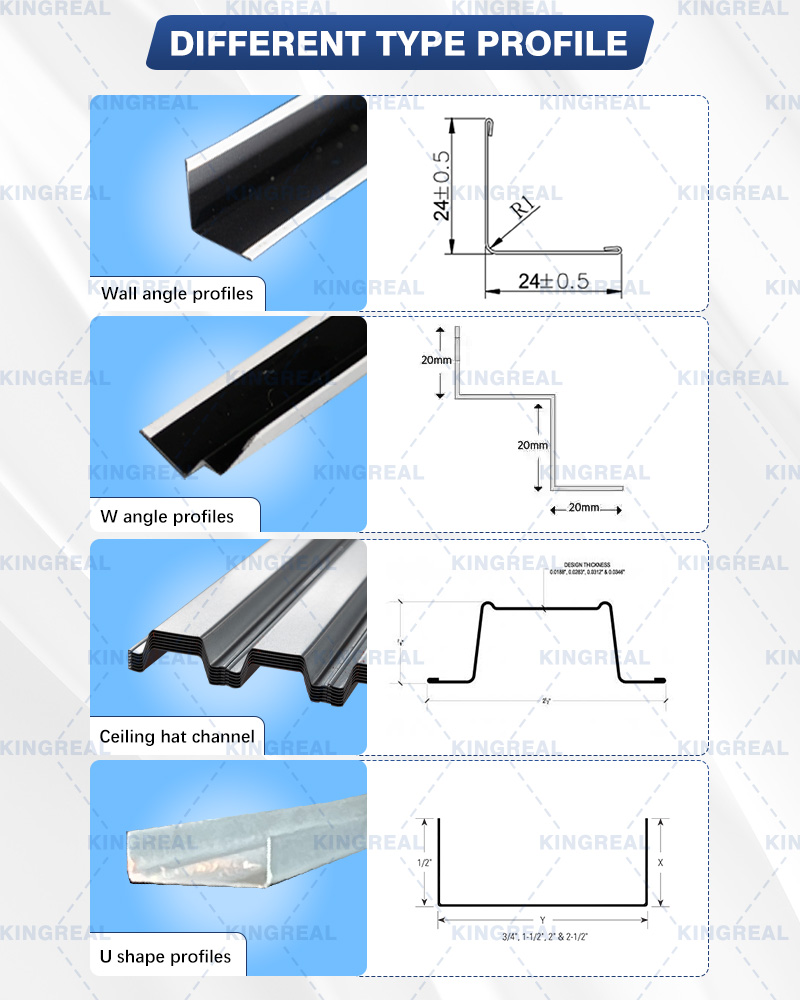

- Features: L-shaped channel has a right-angle design, usually used for edge fixing and support, and is suitable as a frame material for suspended ceiling systems.

- Purpose:

1. Used as the main keel or edge support in the suspended ceiling system to provide the structural framework.

2. It plays a role in fixing the frame in the partition system to ensure the stability of the wall.

U-shaped channel

- Features: The U-shaped channel has a smooth U-shaped cross-section design, which is suitable for larger span supports and can carry larger loads.

- Purpose:

1. Used as the main keel or secondary keel in the suspended ceiling system to provide greater strength support.

2. Used in partition wall systems to provide stable frame support for lightweight wall panels.

Although L-shaped and U-shaped channels are widely used, in specific designs and application scenarios, hat-shaped channels often become the best choice due to their unique hat-shaped designs.

The role of hat channel machine in production

Channel ceiling machine is an indispensable core equipment in the production process of hat-shaped channels, L-shaped channels and U-shaped channels. This equipment uses cold rolling forming technology to process metal coils into the required profiles, which is efficient, precise and stable.

Working principle of hat channel machine

1. Feeding stage: The metal coil is placed in the uncoiling device and is smoothly fed into the machine by the feeding device.

2. Forming stage: Through a series of precision rollers and dies, the metal coil is gradually formed into a hat-shaped, L-shaped or U-shaped cross-section.

3. Cutting stage: After the molding is completed, the automatic cutting system of the molding machine accurately cuts the channel according to the preset length.

Composition of channel ceiling machine

1. Uncoiling device: Unroll the metal coil to ensure continuous feeding.

2. Roller forming system: the core part, which completes the channel forming process through multiple sets of rollers.

3. Automatic cutting system: Equipped with high-precision cutting blades or hydraulic cutting devices to achieve precise cutting.

4. Control system: PLC control system is usually used to realize automated operation and production line management.

Advantages of hat channel machine

- High efficiency: The equipment can process continuously, the production speed is fast, and it is suitable for large-scale production.

- High precision: High forming and cutting precision ensures product quality.

- Versatility: Different types of keels can be produced by changing molds, such as hat-shaped, L-shaped and U-shaped channels.

Combination application of hat-shaped channel and other channels

In actual construction projects, hat-shaped channels are usually used together with L-shaped channels and U-shaped channels.

- Ceiling system: Hat-shaped channel serves as the main load-bearing support, L-shaped channel serves as the frame, and U-shaped channel is used to enhance the stability of the span structure.

- Partition wall system: hat-shaped channels are used to fix decorative panels, U-shaped channels are used as main frame support, and L-shaped channels are used for edge closing and frame fixing.

This combined use method gives full play to the characteristics of various types of channels, which not only ensures the stability of the structure, but also improves the convenience of construction.

Development Trend of Hat Channel Machine

As the demand for hat channels in the construction industry continues to increase, channel ceiling machines are constantly being upgraded to meet market demand.

1. Intelligent: Equipped with an intelligent control system to achieve fully automatic production and real-time monitoring.

2. Versatility: Through modular design, it supports the rapid switching production of multiple keel specifications.

3. Environmental protection: New equipment is more energy-saving and reduces material waste during processing.

Summarize

As a key component in the building system, hat-shaped channels are widely used in suspended ceilings and partition systems due to their excellent support capabilities and smooth installation effects. L-shaped channels and U-shaped channels have their own characteristics in terms of edge fixation and long-span support. The combination of the three can meet various complex construction needs. In the production process of these channels, the hat ceiling machine provides high-quality material support for the construction industry through efficient and precise processing technology.

In the future, with the continuous development of construction technology, hat-shaped channels and other channels will play a greater role, and channel ceiling machines will also continue to move forward on the road of intelligence and environmental protection, bringing more benefits to the industry.