Ceiling T Bar Roll Forming Machine

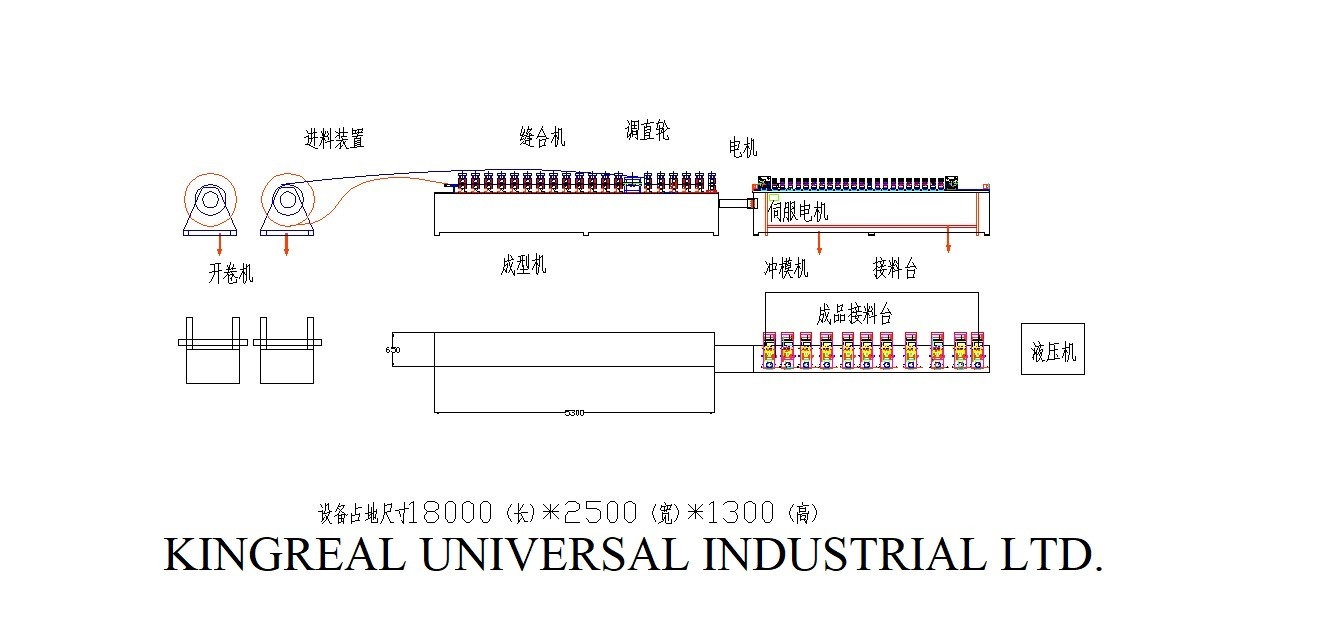

KINGREAL Ceiling T Bar Roll Forming Machine, Ceiling T bar Making Machines series include two machine, one is for the 3600mm length main Tee grid production, the other is for 600mm and 1200mm length Cross Tee bar auto forming.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Ceiling T Bar Roll Forming Machine Specification

| Model | KRTXJ-24 type main "T" ceiling grid production line |

| Raw material | galvanized steel sheet, color coated sheet |

| Thickness of galvanized steel sheet | 0.2-0.35mm, color-coated galvanized sheet thickness 0.25-0.3mm |

| Product specifications | Flat T-shaped keel height 38mm x width 24mm |

Technical parameters | a) Voltage 380v 50HZ (can be changed according to customer requirements) b) Roller press power 3.0kw; hydraulic station drive motor 15kw; transmission motor 1.5kw with accumulator c) Roll material Cr12mov quenching hardness HRC 58-62; CNC machining after quenching. The material of the stamping die is SKD11 die steel |

Production Process

Uncoiling-roll forming-straightening-hydraulic automatic punching, cutting-finished product

Equipment Advantages And Production Capacity

a. Continuous automatic production. After roll forming, it enters the stamping mechanism; when the set length is reached; the forming equipment automatically stops; the rotary encoder sends a signal to the press for stamping; after the stamping is completed, the finished part automatically falls off; the finished part is exported to the press by the conveyor belt; The pressing machine starts automatically; it works in cycles.

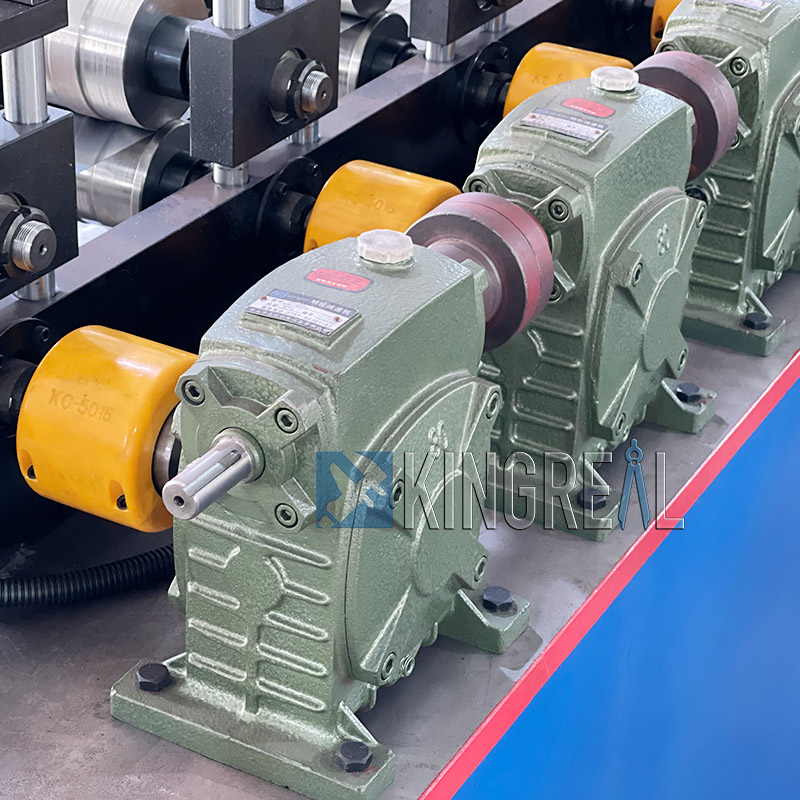

b. Roll forming transmission system: servo motor drive, arc hard tooth surface bevel gear transmission. Gear transmission of the whole machine.

c. Roll forming speed of the production line: the fastest is 25m/min, and the speed can be adjusted.

d. Hydraulic automatic punching-cutting; punching and cutting are automatically completed at one time.The product length and hole spacing are accurate in size. The total length tolerance is ±0.2mm. Tolerance of hole spacing ±0.1mm;The hydraulic system adopts high pressure and high speed; with water cooling system; it can produce without circulation for 24 hours.

e. Production efficiency of automatic production line of paint keel (main T-shaped keel):Production efficiency: 3.66 meters long "main T-shaped" workpiece, 5 pieces per minute.

f. Production area The length of the production line is 19m, the width is 4m, and the height is 1.5m;

g. Independent power distribution cabinet and independent touch screen operation panel.

h. The whole production line is welded by steel plate; the press frame and the stamping mechanism frame are welded and processed after heat treatment.

Main T Bar Line Components

| Name | Unit | Quantity | Remarks |

| Uncoiler | Unit | 2 | Coiled strip discharging device (load 500kg+300kg) |

| Roll forming equipment | Unit | 1 | / |

| Punching machine | Unit | 1 | Main T bar online punching and cutoff |

| Hydraulic system | Set | 1 | punching machine hydraulic station |

| Punching dies | Set | 24 | Stamping die sets 22 punching dies + two-end plug dies 2 sets (plug dies include two punching holes) |

| Finished product Table | Set | 1 | Finished products output table |

| Electrical control system | Set | 1 | including one Power distribution cabinet and one ouch screen operation panel |

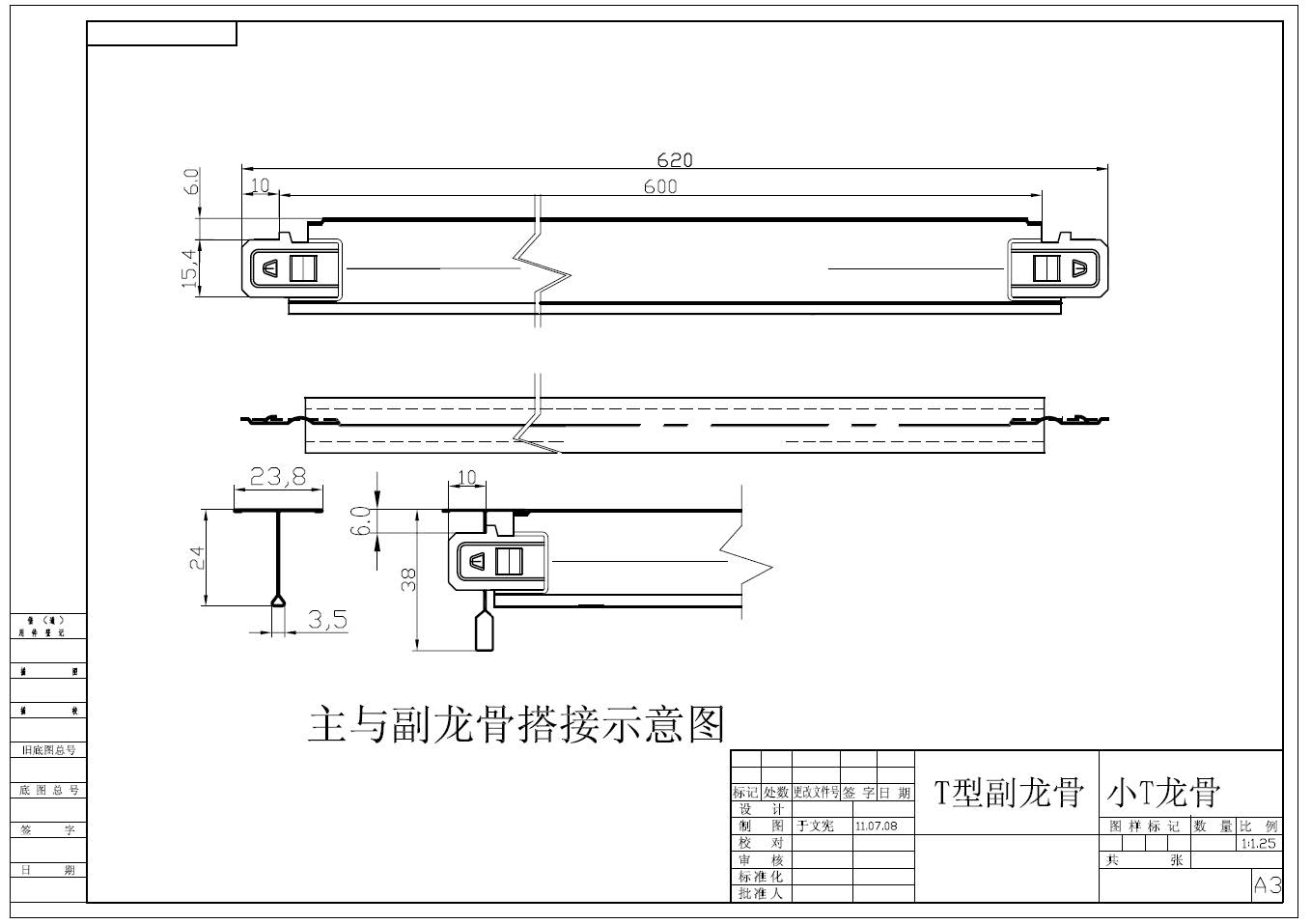

Cross Tee Bar Roll Forming Machine Specification

| Model | KRTXJ-24F type full automatic ceiling cross "T" bar production line |

| Raw material | galvanized steel sheet, color coated sheet |

| Thickness of galvanized steel sheet | 0.2-0.35mm, color-coated galvanized sheet thickness 0.25-0.3mm |

| Product specifications | Flat T gird height 24mm x width 24mm |

Technical parameters | a) Voltage 380v 50HZ (can be changed according to customer requirements) b) Roller press power 3.0kw; hydraulic station drive motor 15kw; transmission motor 1.5kw with accumulator c) Roll material Cr12mov quenching hardness HRC 58-62; CNC machining after quenching. The material of the stamping die is SKD11 die steel |

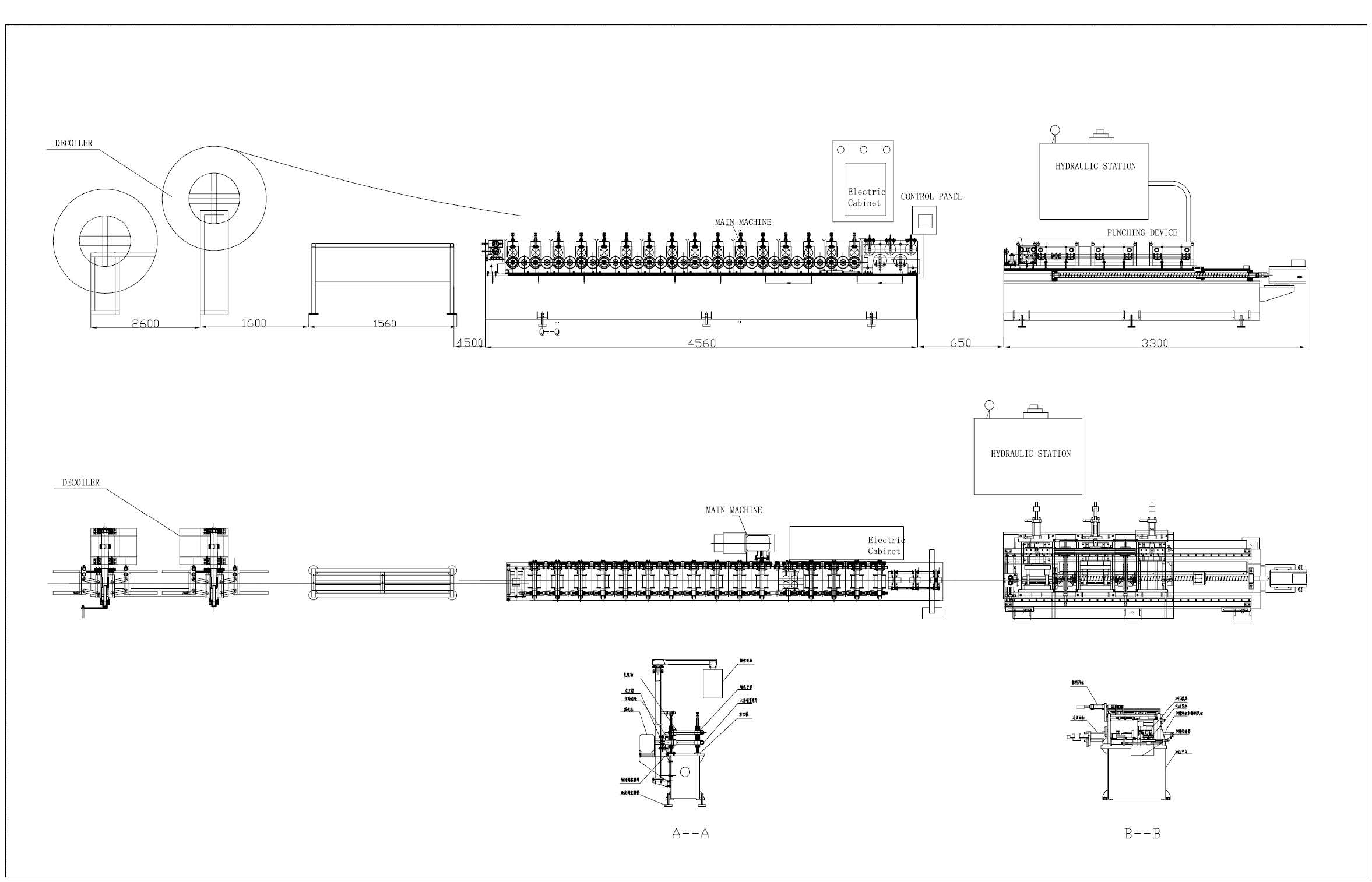

Production Process Of Cross Tee Bar Machine

uncoiling-roll forming-straightening-hydraulic automatic punching, cutting-finished product

Equipment Advantages And Production Capacity

a. Continuous automatic production. After roll forming, it enters the stamping mechanism; when the set length is reached; the forming equipment automatically stops; the rotary encoder sends a signal to the press for stamping; after the stamping is completed, the finished part automatically falls off; the finished part is exported to the press by the conveyor belt; The pressing machine starts automatically; it works in cycles.

b. Roll forming transmission system: servo motor drive, arc hard tooth surface bevel gear transmission. Gear transmission of the whole machine.

c. Roll forming speed of the production line: for the 0.6m cross T bar is about 40PCS/min, for the 1.2m length cross T grid is about 20PCS/min.

d. Hydraulic automatic punching-cutting; punching and cutting are automatically completed at one time.The product length and hole spacing are accurate in size. The total length tolerance is ±0.2mm. Tolerance of hole spacing ±0.1mm;The hydraulic system adopts high pressure and high speed; with water cooling system; it can produce without circulation for 24 hours.

e. Production efficiency of automatic production line of light steel keel (cross T bar):Production efficiency: 0.6 meters long "cross T bar" workpiece, 40 pieces per minute. 1.2 meters long "cross T bar" workpiece, 20 pieces per minute.

f. Production area:The length of the production line is 19m, the width is 4m, and the height is 1.5m.

g. Independent power distribution cabinet and independent touch screen operation panel.

h. The whole production line is welded by steel plate; the press frame and the stamping mechanism frame are welded and processed after heat treatment.

Cross T bar Machine Components

| Name | Unit | Quantity | Remarks |

| Uncoiler | Unit | 2 | Coiled strip discharging device (load 500kg+300kg) |

| Roll forming equipment | Unit | 1 | / |

| Punching machine | Set | 1 | Cross T bar online punching and cutoff |

| Hydraulic system | Set | 1 | punching machine hydraulic station |

| Punching dies | Set | 4 | Stamping die sets 2 punching dies + two-end plug dies 2 sets (plug dies include two punching holes) |

| Finished product Table | Set | 1 | Finished products output table |

| Electrical control system | Set | 1 | including one Power distribution cabinet and one ouch screen operation panel |

Reference Drawing Of Ceiling T Grid

KINGREAL's ceiling t bar machine is designed to meet customers' production needs for different sizes and types of ceiling t bar, with extremely high flexibility and adaptability. Whether it is standard size or customized needs, KINGREAL's t bar roll forming machine can easily cope with it, ensuring that each product can meet customers' specific requirements.

KINGREAL's ceiling t grid making machine is able to produce a variety of types of ceiling t bar, including Black Groove Tee, Flat Tee, Fut Tee, Stereoscopic Groove Tee. KINGREAL's ceiling t bar machine not only ensures the high quality and consistency of the product, but also can flexibly adjust production parameters to meet the changes in different market needs.

New Design -- Ceiling T Bar Machine With Protective Shield

In order to effectively reduce the potential safety hazards that may occur when operating the machine, KINGREAL innovatively invented the ceiling t grid making machine with a protective shield. This innovative design fully considers the dual needs of worker safety and production environment, and greatly improves the safety of the production process.

The ceiling t bar machine with a protective shield can effectively reduce the safety hazards during operation and protect workers from potential injuries when using the equipment by putting a protective shield on the roll forming machine. At the same time, the design of the protective shield can also effectively avoid material splashing and reduce pollution in the factory environment, thereby keeping the production area clean and safe.

KINGREAL has always been committed to providing customers with safe and reliable equipment solutions and continuously optimizing and improving the t bar roll forming machine.