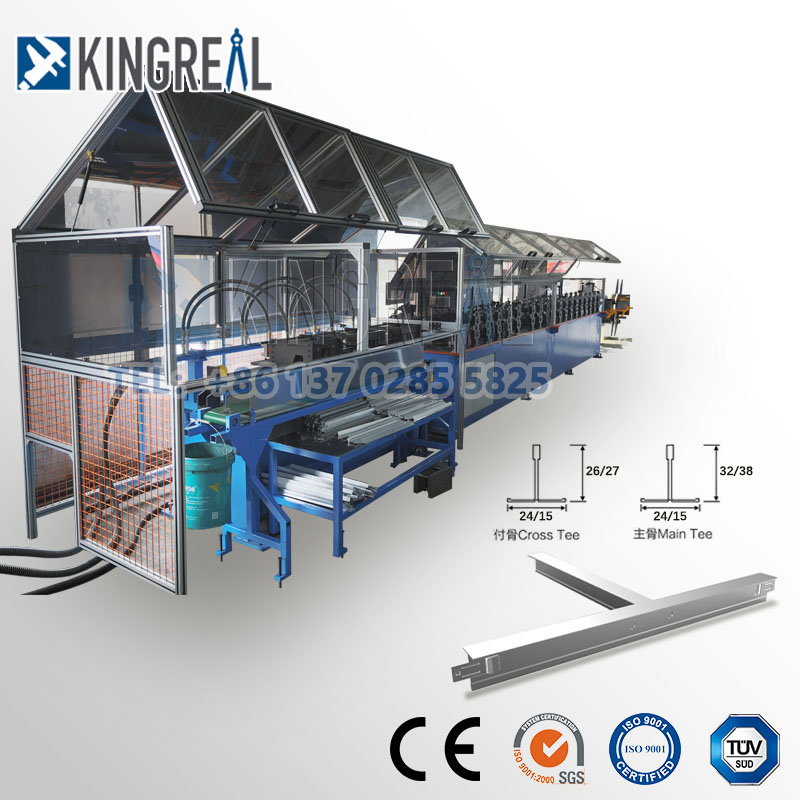

Silhouette T Grid Roll Forming Machine

KINGREAL Silhouette T Grid Roll Forming Machine offers a complete range of equipment s for making Tee Grid ( main T and cross T for hanging different types of suspended ceilings.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

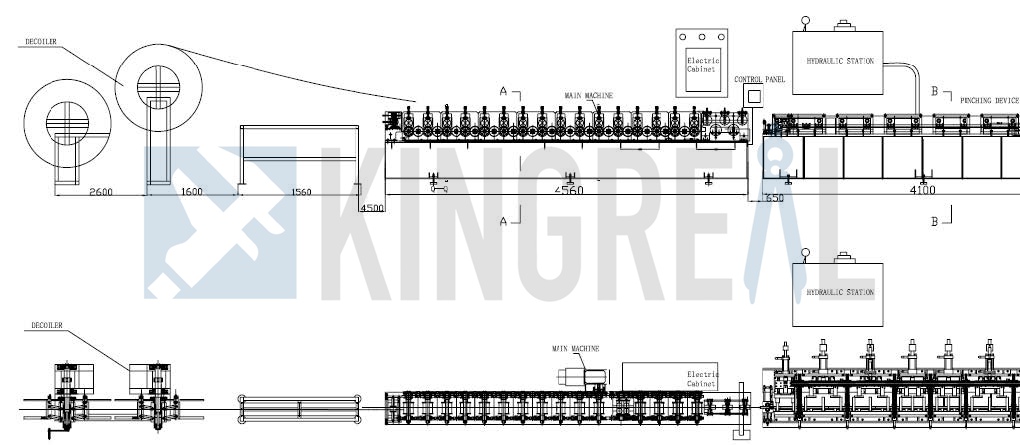

Silhouette T Grid Roll Forming Machine Process

Pre-painted material coil & G.I. material coil - roll forming - hydraulic cutting-off - Main Tee Grid / Cross Tee Grid / Wall Angle Profile (Roll Formed) - Opening Punching (Power Press)

Cross Tee Grid Making Machine

The profile forming process: Passive decoiling--- 15T hydraulic hole punching, reinforcing bid pressing---material feeding--- roll forming--- straightening--- hydraulic cutting off---- material unloading, all the process finished automatically.

Technical Specification

| Power supply | voltage 380V±10%/ three phase four wire, frequency 50HZ. |

| Total power | 12kw |

| Air rate | 10.0L/min (air pressure 0.4-0.6Mpa) |

| Environment temperature | 0°C-40°C, relative humidity: 60-95%RH |

Auto Ceiling T Bar Production Line Compoesition

The whole line is composed by decoiler, hydraulic punch press, feeding device, roll forming machine, straightening device, hydraulic cutting off, cold water recycling device, pneumatic and electric control system, etc.

1. Decoiler (as drawing) Bearing 1T, Inner diameter φ450-530mm, out diameter φ1200mm. 2) Rack a. One piece construction, the roll forming device, straightening device, cutting off device is a whole unite. The rack receives heat treatment after welded, fine finished surface, which ensuring the intensity, rigidity, stability and accuracy of the machine. b. All the components of the machine received necessary surface treatment according the actual working situation and environments, like electroplating, hardening, etc to ensure the enough rigidity and surface function of the components. 3) Feeding device: synchronism adjusting rollers. 4) Punching Machine This line equipped with 15T hydraulic punching machine. |  |

5) Roll Forming Machine Roll Forming rollers: material GCr15, hardness after heat treatment HRC48-50, hole diameter (roller shaft diameter) φ42mm, the min. outside diameter of rollers isφ100. 6) Transmission Device: (as drawing) a. Main motor (Jiangmen Jiangyan motor), Frequency control. b. The driving rollers are driven by three sides belt, the passive rollers are driven by gears, with center distance a=75, reduction ratio i=30 worm gear case, gear mould m=5. Main side plate thickness: 30mm, deputy side plate thickness: 25mm. Finished by six sides grinding and boring holes treatments. c. The material of main shaft is 40Cr, finished after heat treatment and refine grinded. |  |

9) Hydraulic Cut Off device: (as drawing) a. Hydraulic system: the system has unloading protect function, the hydraulic components use Taiwan Dazheng brand. b. Mould rack: the mould plate closed height is 260mm, the adjustment range of the closed height is 20mm, the max. stroke of oil cylinder is 100mm. c. There is straight guide track under the mould rack (ABBA brand), the relocation of the mould rack replying the push of buffer pneumatic cylinder. d. The cut off mould: design as the botch of the production, equip with another cut off mould. 10) Straighten device: use five roller straightening device. (as drawing) 11) Unload of the material: the production is guided out through material guide slot. 12) Cold water cycling system: the roller are equipped with cold water pipes, use electric water pump, the cold medium is emulsified oil. |  |

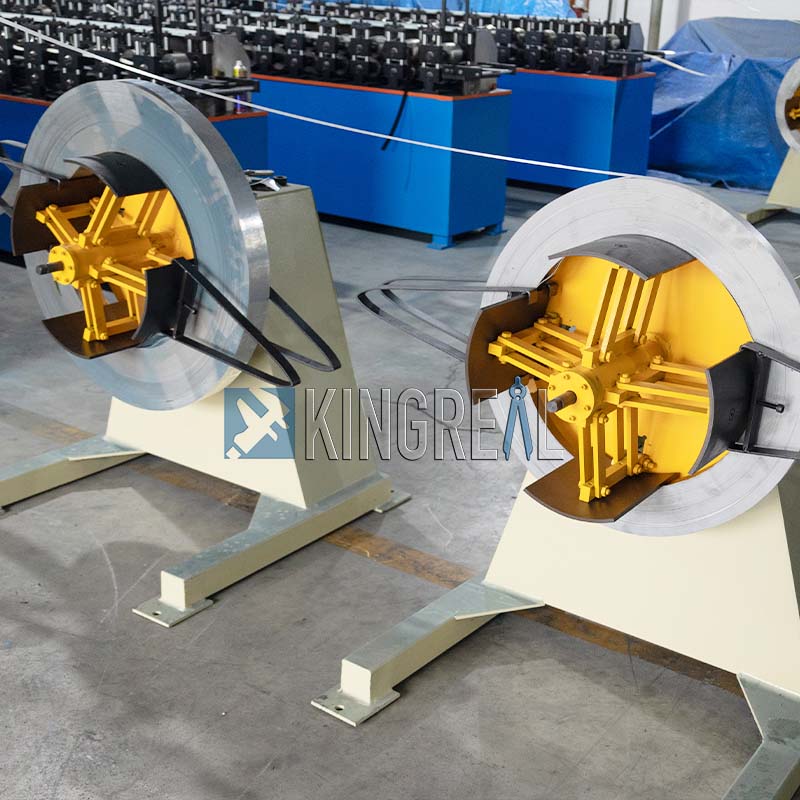

13) Electric system a. Use frequency converter, centre auto control, use the fixed rule to adjust the length and automatic cut off. The air switch and contactor us Japan Fuji, reply use Japan Izumi, the button use French Schneider, other components use good quality imported production. b. The whole line use centre control, the roll forming machine and hydraulic machine is combined moving. When the punched mould is cutting off, the roll forming machine is in low speed automatically, when the cut off is finished, it moves in high speed automatically. The hydraulic machine work separately. c. The control panel is composed by human-machine interface, button, switch, emergency stop, etc. The mark is clear and the panel is easy to operate. Using multi positions operation, the main control panel is located in the middle of hydraulic machine and roll forming machine, equipped with hand controller, which make the operation more convenience. d. Alarming function: stop when lacking material, count the numbers, stop when the production number is finished, alarming when transmission failure, emergency stop, mould stuck, position limited, etc. e. The installation of electric components meets the requirements of legal. We supply reliable earth contacting device, the wire terminal blocks of electric box, contactors, switches are all installed with V shape guide slots. All the electric components have clear marks. In the electric cabinet, we use anti-flaming plastic slots to arrange the wires. The number of the wires is clear, the layout of the components is reasonable, the control panel is tidy, the marks are clear. |  |

Special Design For Silhouette T Grid Machine

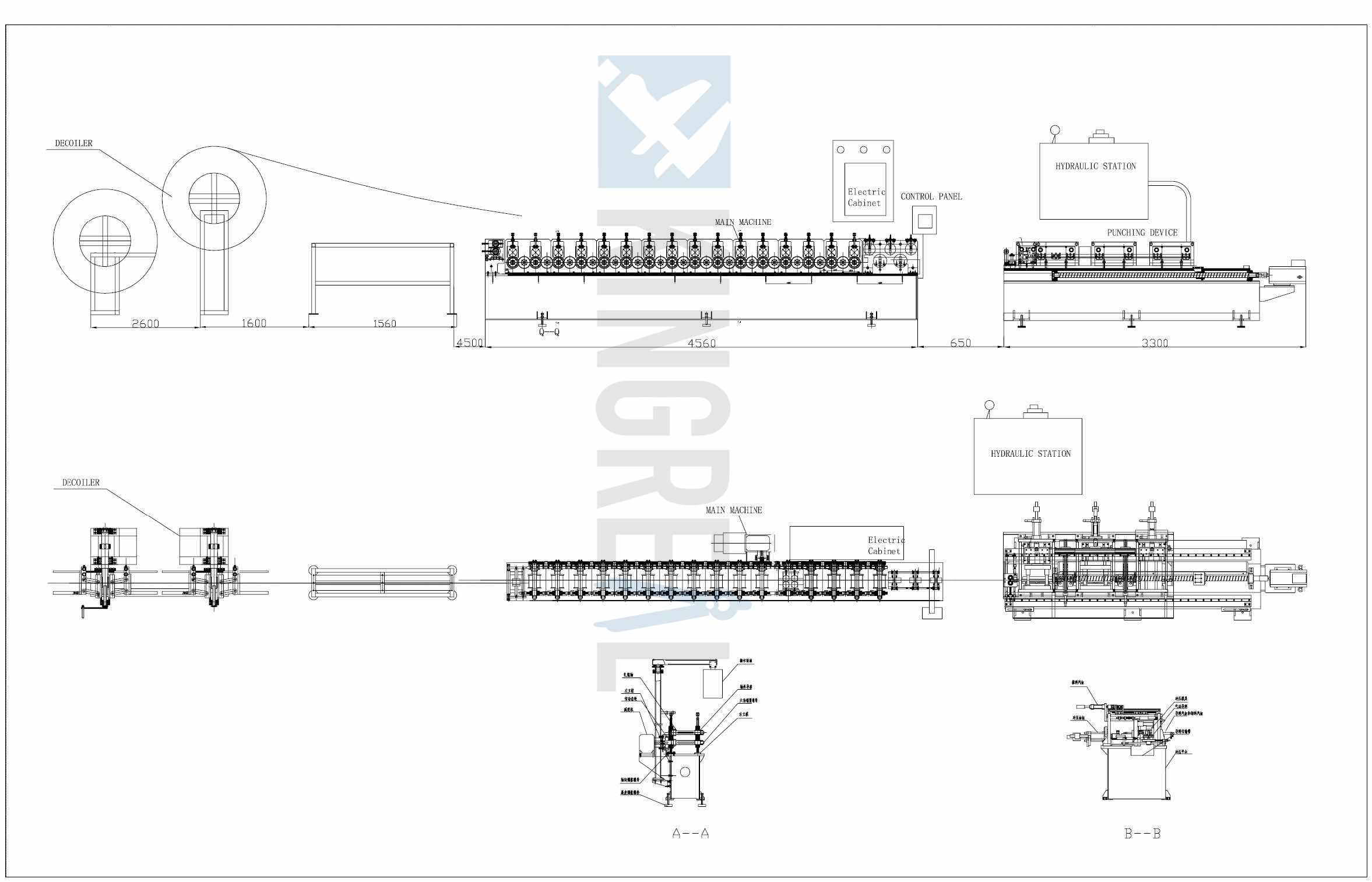

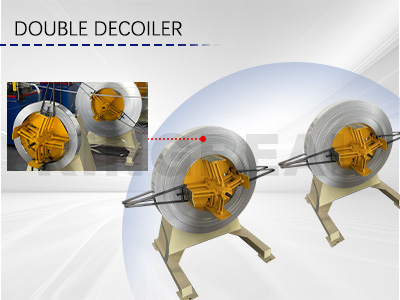

Double Decoilers

In order to further improve production efficiency, KINGREAL equipped the silhouette grid ceiling machine with two decoilers. This innovative design not only achieves a higher unwinding speed, but also effectively reduces the time of reel change during the production process.

Add Logo

In order to enhance the market competitiveness and uniqueness of customers' finished products, KINGREAL provides customized services for printing customer logos on the rollers. When the metal sheet is pressed by the rollers in the roll forming machine, the customer's logo will be printed on the finished product at the same time. This not only makes the product more professional and unique in appearance, but also effectively improves brand recognition.

Other Advantages Of KINGREAL T Bar Roll Forming Machine

1. Pneumatic components: use famous Taiwan brand.

2.Safety protection. The installation of electric components is according the regulation of China, we supply reliable earth contacting devices. There are emergency stop button at the punching side.

3. The color of machine. The color of main equipment is according the requirement. The alarming marks are sticking to the safety position where is dangerous for human.

Quality Control

1) After the installation, debugging of the machine by the supplier in the factory, then the buyer check and accept the machines.

2) The supplier is in charge of training the buyer’s worker about the operation and maintenance principle, the knowledge of rejection of the usual failure of machine, the safety attentions and the daily maintenance.

Ceiling T Bar Sizes For Your Reference

By using best materials to assure highest strenght with perfect surface quality. Please find below specifications we normally produce:

Ceiling T-bars

Main Tee:H38*24mm, H32*24mm

Cross Tee:H26*24mm, H24*23mm

Angle:22*22, 22*20MM

Thickness:0.20-0.40mm

Length can be supplied as buyer requested

1) To fix mineral fiber board or PVC laminated gypsum board and other Ceiling board.

2) Available models:

| A) 32H Model: I) Main tee: 32mm x 24mm x 3.0m, or 3.05m, 3.60m, 3.66m Ii) Cross tee: 26mm x 24mm x 1.2m, or 1.22m Iii) Cross tee: 26mm x 24mm x 0.6m, or 0.61m Iv) Wall angle: 20mm x 20mm x 3.05m, or 3.60m 22mm x 22mm x 3.05m, or 3.60m 24 mm x 24mm x 3.05m, or 3.60m V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm | B) 38H Model: I) Main tee: 38mm x 24mm x 3.0m, or 3.05m, 3.60m, 3.66m Ii) Cross tee: 26mm x 24mm x 1.2m, or 1.22m Iii) Cross tee: 26mm x 24mm x 0.6m, or 0.61m Iv) Wall angle: 20mm x 20mm x 3.05m, or 3.60m 22mm x 22mm x 3.05m, or 3.60m 24 mm x 24mm x 3.05m, or 3.60m V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm | C) 32H Model(9/16): I) Main tee: 32mm x 14.5mm x 3.0m, or 3.05m, 3.60m, 3.66m Ii) Cross tee: 32mm x 14.5mm x 1.2m, or 1.22m Iii) Cross tee: 32mm x 14.5mm x 0.6m, or 0.61m Iv) Wall angle: 20mm x 14mm x 3.05m, or 3.60m V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm | D) 38H Model(9/16): I) Main tee: 38mm x 14.5mm x 3.0m, or 3.05m, 3.60m, 3.66m Ii) Cross tee: 38mm x 14.5mm x 1.2m, or 1.22m Iii) Cross tee: 38mm x 14.5mm x 0.6m, or 0.61m Iv) Wall angle: 20mm x 14mm x 3.05m, or 3.60m V) Thickness: From 0.23mm, 0.25mm, 0.28mm, to 0.30mm and 0.40mm Besides ceiling suspension systems,we also produce steel strut channels. |