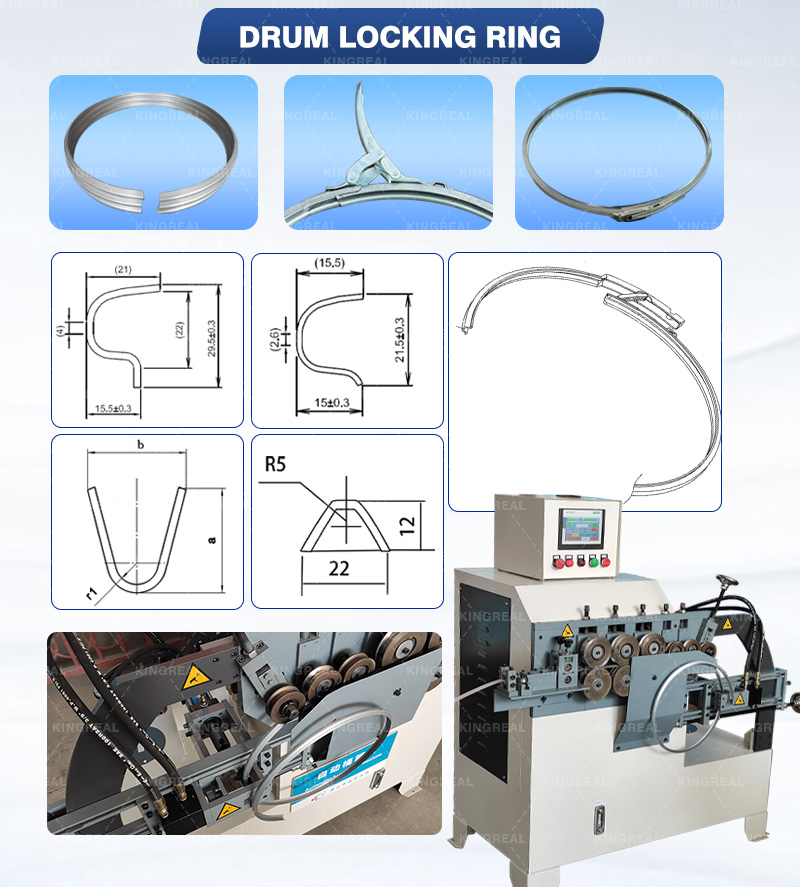

Drum Clamping Ring Welding Machine

KINGREAL barrel hoop forming machine / drum clamping ring welding machine / drum locking ring making machine, this machine is cut off once. Drum clamping ring welding machine is divided into three axes, four axes, five axes, six axes, and ten axes.

- KINGREAL

- China

- 40 Days

- 9999

- Information

Description Of Drum Clamping Ring Welding Machine

KINGREAL barrel hoop forming machine / drum clamping ring forming machine / drum locking ring making machine, this machine is cut off once. It is divided into three axes, four axes, five axes, six axes, and ten axes.

This drum closure making machine is suitable for material thickness 0.7-3mm (galvanized sheet, cold rolled / hot rolled sheet), suitable for raw material width ≤ 52mm, this machine and resistance butt welding unit synthetic hydraulic steel ring forming and welding production line.

The whole clamping rings making machine is compact in structure, accurate in materials, reasonable in processing and heat treatment, high in precision and strength, and long in service life. The style is novel, the structure is reasonable, the voice is low, and the operation is simple. Full-featured and highly self-contained.

Applicable Manufacturing

Metal barrel locking rings, chemical barrel clamping rings, paper barrel closure ring, convenient buckets rings, vacuum cleaner barrel, quick release barrel, barrel barrel of fish barrel hoops

Specializing in the production and manufacture of various types of welding equipment and iron wire products complete sets of special equipment.

Component Details

⊙ AC resistance welding machine; foot (pneumatic) spot welding machine, butt welding machine, welding machine, welding machine, projection welding machine;

⊙Wire processing machine: automatic buckle machine, hook machine, bending machine, flattening machine, straightening and cutting machine, trimming machine, circular machine, chain machine, knotting machine,

⊙Special complete equipment: bag dust removal cage skeleton complete equipment, process lamp cover whole plant equipment, fan net cover manufacturing whole plant equipment, storage layer frame basket automatic production complete equipment, cement pole complete set steel forming processing equipment, metallized film capacitor Manufacture of whole plant equipment, wire tube condenser complete automatic production line.

⊙Special welding equipment; automatic water tank rolling welder, fried blue roller welder, copper and aluminum pipe joint welder, flash butt welder, precision single, double, multi pulse welder, secondary rectification welder, capacitor energy storage point Welding machine, seed welding machine, high frequency brazing machine, automatic argon arc welding machine, automatic seam welding machine, flat net gantry type welding machine, various non-standard special welding machines

And KINGREAL clmaping rings making machine is widely used in hardware appliances, automotive hardware accessories, communication, lighting, lampshades, kitchen utensils, shelves, blue, racks, wire crafts, outdoor furniture, office stationery, file cabinets, decorative crafts, environmental dust removal equipment, musical instruments, Electrical, electrical, battery and other manufacturing and industrial equipment automation.

Clamp Locking Ring Product

Strip steel, sheet (thin sheet) rolled into: grooved steel ring, all kinds of rims, such as baby carriage ring forming machine, clamp ring making machine, tight lock steel ring roll forming machine.

Special feature

This barrel hoop ring making machine is the star product of this year, which brings together the essence of similar equipment at home and abroad. Its structure is compact, reasonable, small in size, low in noise and beautiful in appearance.

KINGREAL clamping rings making machine product manual

Advanced, stable, fast, accurate, power-saving, high degree of automation, easy to operate:

1. Pressure groove, winding, cutting, as one, once completed.

2. Using the special program controller of the circular machine, there are two kinds of electrical controllers and liquid crystal displays. With the output setting (control) function, when the output reaches the set value, it will automatically alarm or stop. There is an accumulation count function. With a high pulse encoder, the feed length is high.

3. Full hydraulic drive, most imported hydraulic components, which use Taiwan oil pumps, motors and so on.

4. It has automatic unloading function. When there is no work, the hydraulic pressure is automatically removed, which reduces the compression time of the components and helps to prolong its service life.

5. With the function of retracting, rewinding and rewinding during debugging to avoid material waste.

6. Using full hydraulic drive, cut off, oil motor to send the line, more power-saving than other forms of drive.

7. The pressure groove adopts the gantry type double pulley to ensure the wire feeding line is stable and accurate.

The materials are excellent, the processing and heat treatment process are reasonable, the comprehensive mechanical properties of the parts are high, the wear resistance is good, and the service life is long:

The grooved wheel, guide wheel and coil forming wheel are made of high quality alloy steel and heat treated by vacuum. The hardness is up to HRC60-62, which has high wear resistance and long service life. The shafts are all made of 40Cr and 45# steel, and they are quenched and tempered. The comprehensive mechanical properties are high. The gears are all made of 40Cr and 45# steel forging billets, and the quenching and tempering and high-frequency quenching of the tooth surface. Hardness up to HRC52-55.

Related Project

KINGREAL has successfully sold many drum clamping ring welding machines to many countries, including India, Vietnam, the United States, Chile, South Korea and Indonesia, etc. These countries have different demands for drum locking ring making machines in industrial production, and KINGREAL ensures that each barrel hoop forming machine sold can perfectly meet the production needs of customers through targeted customized services.