Fire Damper Frame Roll Forming Machine

KINGREAL successfully developed and manufactured a fire damper frame roll forming machine for the fire damper frame / smoke damper frame.

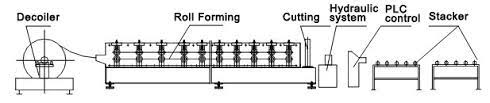

Fire damper frame roll forming machine is controlled by the PLC, including the material decoiler, leveling and pre-punching station, roll forming main machine and auto bending machine.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Fire Damper Frame Roll Forming Machine Description

KINGREAL successfully developed and manufactured a fully automatic production line for the fire damper frame / smoke damper frame. It is controlled by the PLC, including the material decoiler, leveling and pre-punching station, roll forming main machine and auto bending machine.

The line speed is about 0-13m/min, which is suitable for the production of various sizes fire damper frames. Combining with the fire damper blade forming machine and the fire damper multi-function riveting platform, a fully automatic fired damper production workshop is formed, which greatly reduces labor costs.

To meet different production needs, this fire damper frame manufacture equipment is designed to produce two types of frame products, one new type of integrated hand-folded frame, and a TDF corner-coded riveted frame. So the fire dampers can be produced by high-efficiency application of new technology, and can also meet the request of traditional technology.

PRODUCTION PROCEDURE

roll material-leveling-shearing-punching and cutting corners-frame roll forming (two kinds of frames can be formed)-cutting-(one-piece manual folding)-riveted frame bending

Fire Damper Frame Production LINE COMPONENTS

1. One material Decoiler 2. One set of leveling, punching and shearing machine 3. Main damper frame roll forming machine, one unit 4. Six sets of punching dies 5. A set of workbenches 6. One folding shearing machine 7. A set of control system |  |

Full Automatic Fire Damper Frame Making Machine Advantages

- no waste is generated during the production process, saving material costs; - different smoke damper frame sizes can be input at one time, and different sizes of fire damper frames can be continuously produced with high production efficiency. - Saving labor cost of the traditonal manual punching, bending production. -Good stability. KINGREAL's raw material selection, quality inspection process, guaranteed fire damper frame production line with high strength and high cost work environment from beginning to end. -Fast speed. KINGREAL fire damper frame making machine’s production speed is fast, reaching the highest performance at 13m/min. In addition, the speed can be set to meet the demands of the production industry. |  |

KINGREAL cold-forming equipment offers these advantages

1. The equipment control is PLC control, and multiple safety protection is set during normal production.

2. The bed is welded with steel plates. It is also tempered to eliminate internal stress and avoid deformation of the fuselage.

3. The forming frame is cast iron structure and tempered. High strength and long service life.

4. The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

5. The material of the forming mold is GCr15, quenching treatment, hardness: HRC 56-62 °C.

6. The transmission structure is gearbox transmission. Each molding frame has a gearbox that guarantees time-out, high-intensity operation and long service life

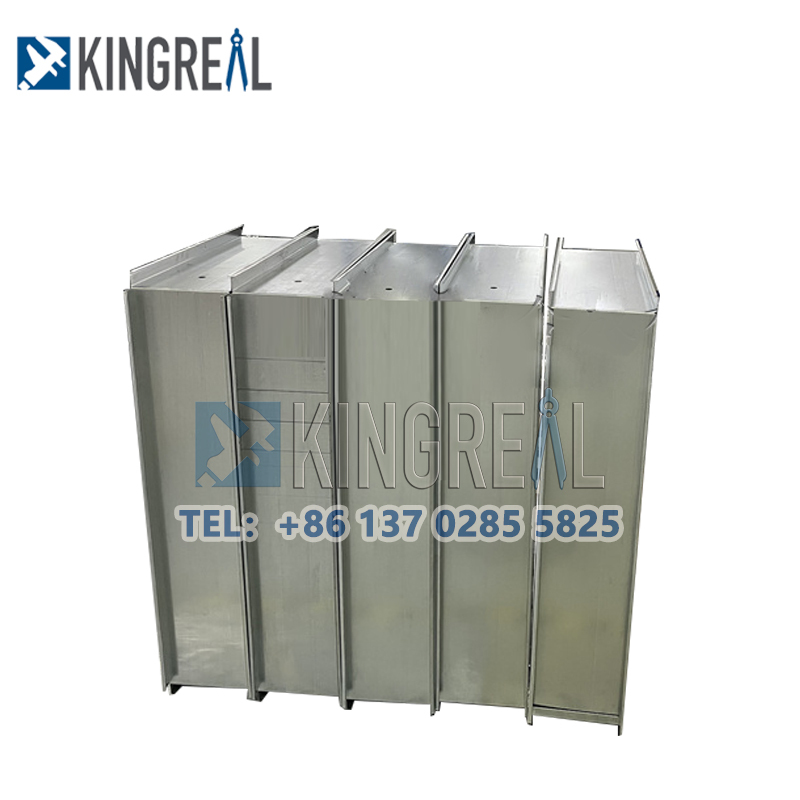

Fire Damper Frame Product

Fire damper is one of the most frequently used damper’s styles in the HVAC system. It is a comprehensive safety system for use with wind and air systems, to prevent fires from spreading within existing structures. Automotive shut down or manual operation method, prevent smoke and fire from passing through the wind, and protect construction safety and resident life.

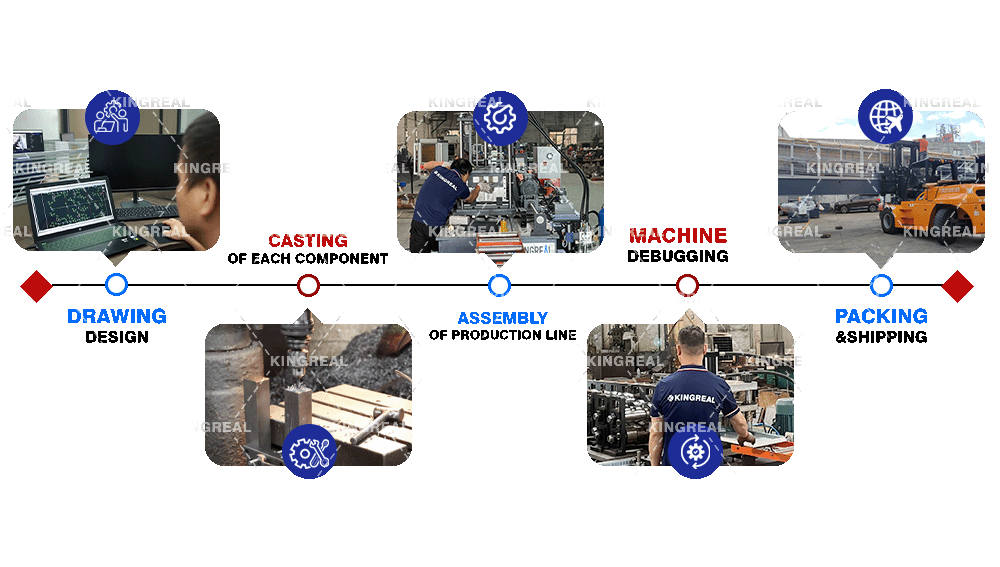

Order Process

Customer Visit

KINGREAL sincerely welcomes customers from different countries to visit KINGREAL's factory. KINGREAL knows that face-to-face communication and field visits are the best way to understand products and services. Therefore, KINGREAL will provide all-round support and services to every visiting customer.

Professional explanation and on-site demonstration

During the visit, KINGREAL will send experienced professional staff to accompany the whole process and explain the fire damper frame making machine's operating principles and technical characteristics in detail to customers. By watching the actual operation of the fire damper machine on site, customers can more intuitively understand the performance and advantages of the machine and enhance their trust in KINGREAL products.

Customized manufacturing solutions

In addition, KINGREAL's team of engineers will tailor personalized fire damper frame making machine manufacturing solutions for customers based on the drawings and specific needs provided by customers. Whether it is equipment configuration for specific production processes or design adjustments based on customers' special requirements, KINGREAL can provide professional solutions to ensure that customers' expectations and needs are met.