Volume Control Damper Frame Roll Forming Machine

As one of the professional manufacturers of roll forming machines in China, KINGREAL can customize and design different Volume Control Damper Frame Roll Forming Machine according to different production needs of customers. Welcome to contact us.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Description Of Volume Control Damper Frame Roll Forming Machine

KINGREAL VCD Frame Making Machine is design to produce different types VCD Frame, such as VCD with flange and without flange. And Fire Control Damper Frame Roll Forming Machine is KINGREAL's self-developed full-automatic production line with high efficiency. This production line adopts new riveting technology to solve problems due to welding technology. The whole line is standard type, high-efficient and smart, which make it the first choice for producing fire control dampers.

KINGREAL VCD Frame Roll Forming Machine can bend, fold and weld metal sheets according to specific shapes and sizes, and finally form the structure of dampers frame. This kind of machine and equipment usually consists of automatic control system, processing tools, transmission devices, etc., which can achieve efficient and accurate production of metal dampers outer frame.

Technical Specification Of VCD Frame Machine

Machine Name | VCD Frame Making Equipment |

Products Name | Volume Control Damper |

| Brand | KINGREAL |

| Automation | Manual Operation/Full-Automatic Production with PLC |

| Certificate | CE certificate, ISO 9001 certificate |

Machine Power | 380V 50HZ or according with customers‘ request |

Speed | 0-15m/min, Hydraulic Follow Shearing System |

Min Frame Sizes | 120*120mm |

Coil Weight | ≤3000kg |

Length Tolerance | ±0.3mm/1000mm |

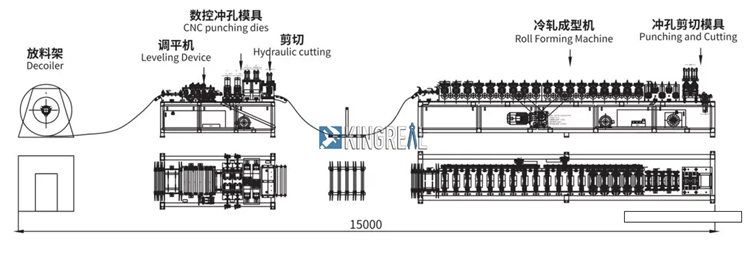

Working Process Of VCD Frame Roll Forming Machine

Hydraulic Decoiler -- Precision Straightener -- Hole Punching System -- Main Roll Forming Machine -- Hydraulic Bending Cutting Station -- Output Table

Advantage Of This VCD Frame Machine

Multi stations hydraulic punch system KINGREAL's multi-station hydraulic punch system can be designed to fit hole positions of different profiles for performing punching operations such as multi-station punching and corner cutting. The system is fully automatic and easy to use. It is suitable for production of shelf columns and furniture profiles. |  |

Overall solution including punching, bending, forming, welding, etc. KINGREAL can provide a overall solution according to customer needs, including product punching, automatic forming, bending, welding, etc.This solution is widely used in full automatic production of various complex profiles, such as closed complex profiles, shelf columns, etc |

|

Highly automatic KINGREAL's vcd damper machine uses highly automated equipment, which significantly improves production efficiency and product quality. The entire production process, including the uncoiling, leveling, punching, forming and cutting of metal raw materials, is completed by advanced automated machines. These automated equipment not only reduces the need for manual operation, but also reduces the possibility of human error, ensuring a smooth and efficient production process. |  |

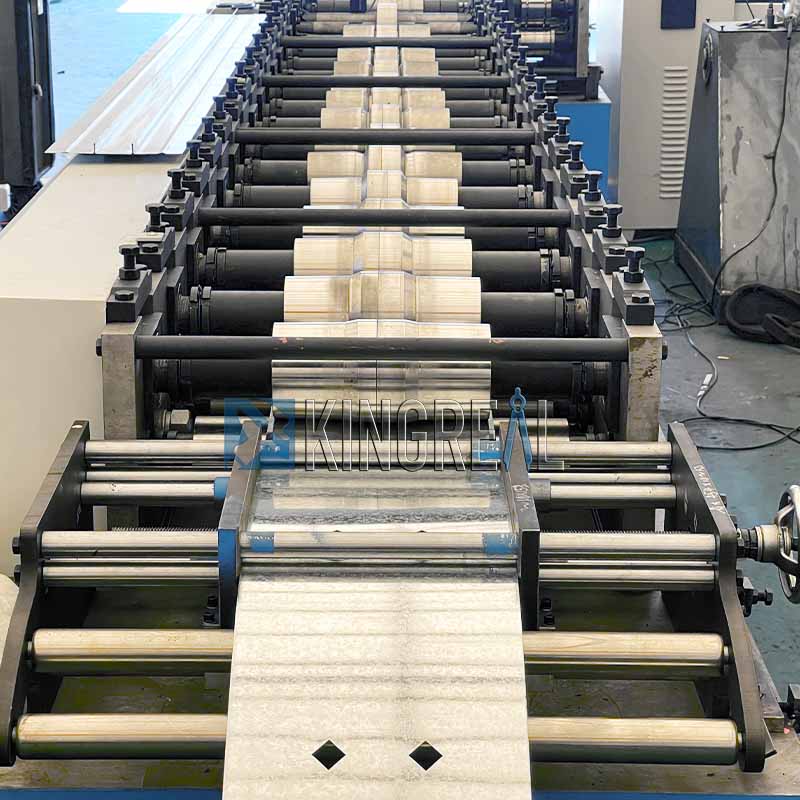

Excellent forming effect KINGREAL has invested a lot of resources in the forming technology of vcd damper frame machines, especially in the manufacture of roll forming machine’s rollers, using strict quality control measures. The design and manufacture of each roller is precisely calculated and rigorously tested to ensure that it minimizes the wear on the galvanized sheet during the forming process. This means that the finished product processed by the KINGREAL volume control damper machine is not only smooth and exquisite in appearance, but also able to maintain the integrity of the galvanized layer, effectively preventing rust and corrosion. |  |

High-precision

KINGREAL vcd damper frame machines have extremely high requirements for the precision of VCD dampers during the production process. Under the same parameter settings, the volume control damper making machine can maintain a highly consistent production effect, ensuring that each vcd damper meets strict quality standards. This high-precision manufacturing capability means that customers do not need to worry about performance issues caused by product differences when using KINGREAL volume control damper machines. |  |

What Is Volume Control Damper Frame?

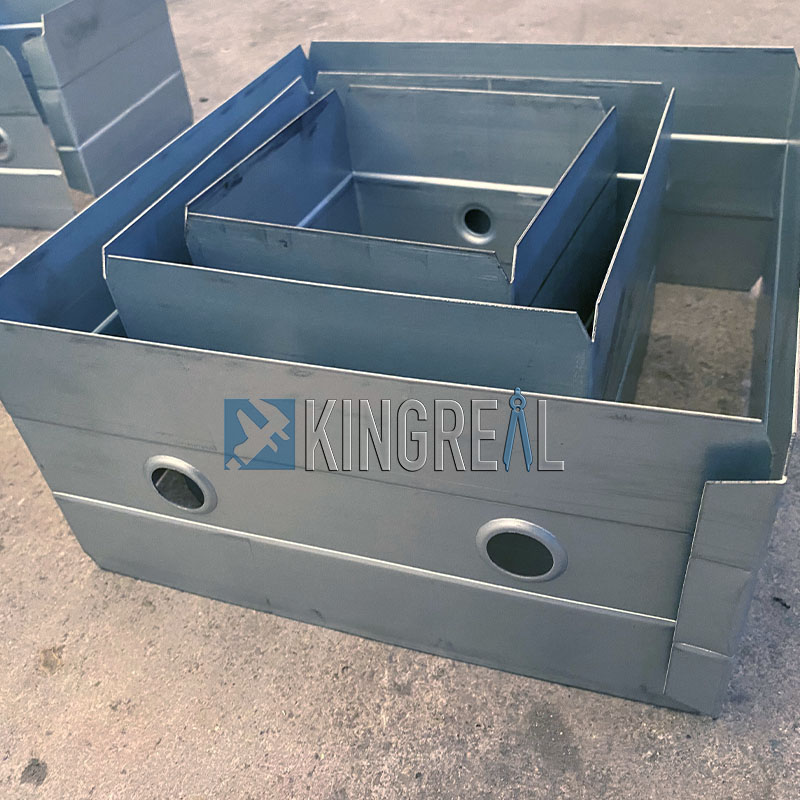

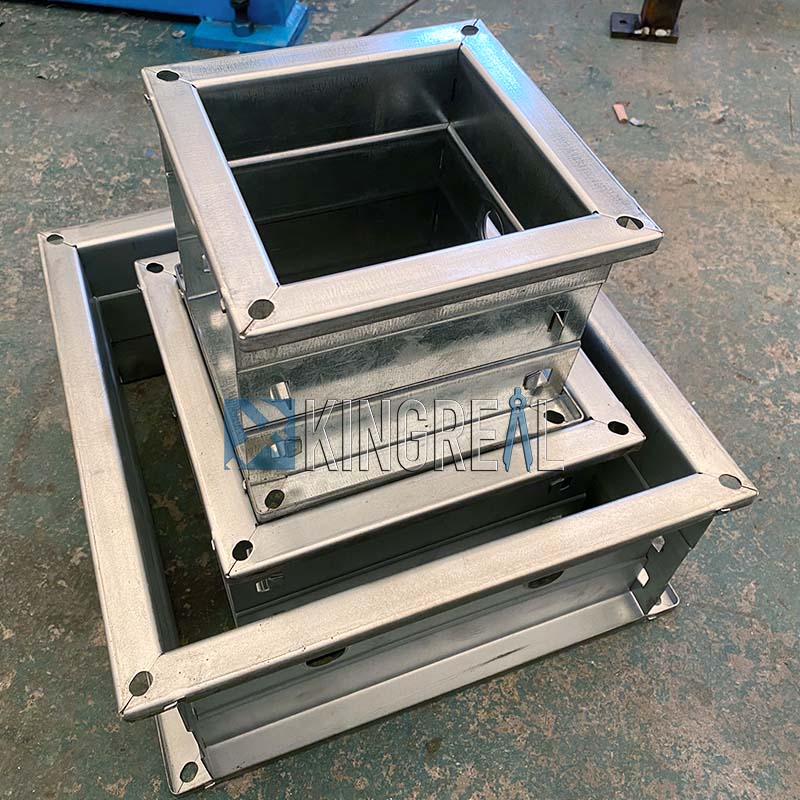

The VCD frame is the external frame structure of the dampers made of metal. It is usually made of aluminum alloy, stainless steel or steel with high strength and corrosion resistance. The main function of the metal VCD frame is to support and fix the internal components of the dampers to ensure the normal operation of the dampers.

What Our Machine Can Do?

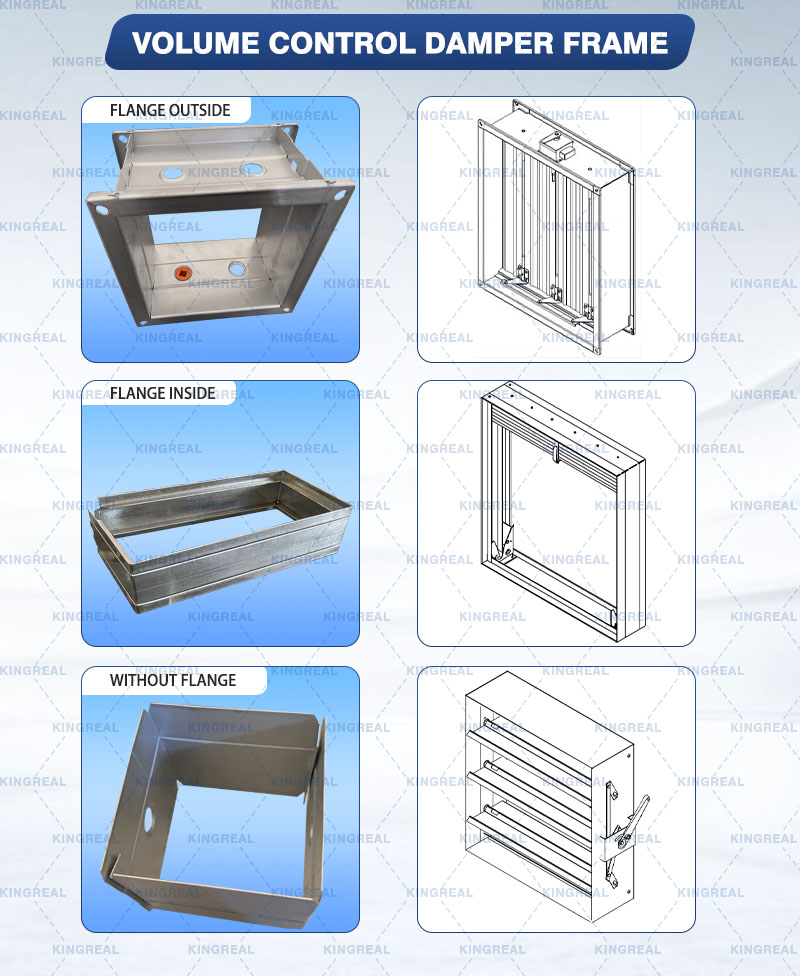

KINGREAL's vcd damper frame machine can produce vcd dampers of different sizes and types, including VDC Frame Without Flange, VCD Frame Flange Inside and VCD Frame Flange Outside.

- VDC Frame Without Flange:

This damper has no outer flange and is usually designed with a flat edge for direct connection with other equipment.

- VCD Frame Flange Inside:

This type of damper has an inner flange, which is located inside the damper and is usually used to connect the damper to the duct or other equipment.

- VCD Frame Flange Outside:

This type of damper has an outer flange, which is convenient for connection to the duct or other equipment, providing additional installation flexibility.

Application Of VCD Frame

Metal air damper outer frame is commonly used in the ventilation system of buildings. It is mainly used to control and regulate air flow to maintain indoor air quality and temperature. It is usually installed at the inlet or outlet of ventilation ducts to control the flow of air by adjusting the degree of opening of the valve.

Metal damper frames can also be used in conjunction with other ventilation equipment such as fans and air conditioning systems for more precise air conditioning.

How To Install The Machine?

In order to help KINGREAL's customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

KINGREAL's Customer

KINGREAL is a roll forming machine manufacturer with more than 20 years of rich experience. It occupies a leading position in the industry with its excellent technology and high-quality products. KINGREAL has established close cooperative relations with customers from many countries, including Russia, India, Indonesia, Saudi Arabia, Turkey, the United States, the United Kingdom and many other countries and regions.

If you are interested in KINGREAL's machine, please feel free to contact KINGREAL. No matter where you are, KINGREAL will wholeheartedly provide you with quality products and services!