Full Auto Ceiling Channel Roll Forming Machine

KINGREAL can provide customers with different types of Suspended Ceiling Channel Roll Forming Machine, including furring channel, wall angle and u shaped metal profile. Contact us for the latest quote

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video Display About Ceiling Channel Roll Forming Machine

Ceiling Channel Machine Description

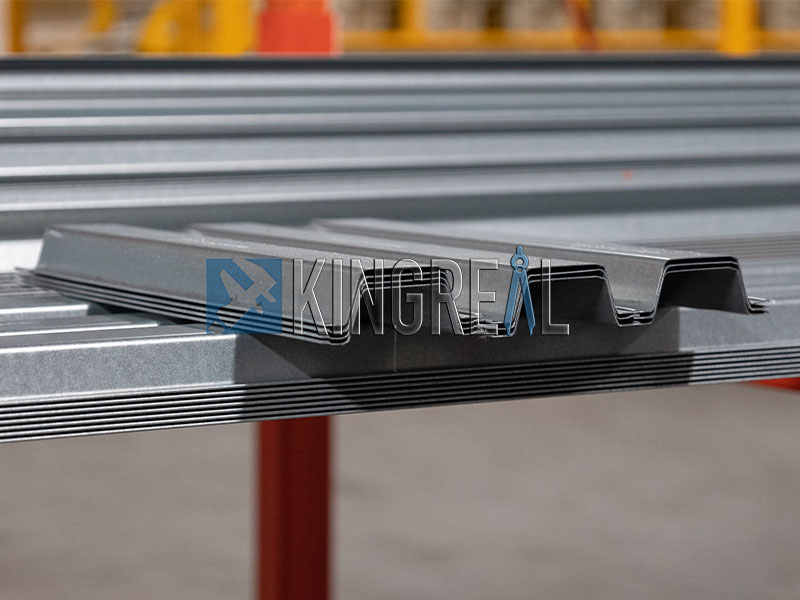

KINGREAL Suspended Ceiling Channel Roll Forming Machine is a machine designed to produce metal frames profile for suspended ceilings. These metal profile are commonly used in ceiling systems in commercial and residential buildings to support lightweight building materials and to conceal wires and pipes. The machine processes metal strips through a continuous cold roll forming process into the desired ceiling beams, primary keel, secondary keel and other profiles.

The working principle of the Suspended Ceiling Channel Rolling Forming Machine is mainly based on the continuous cold rolling forming process, whereby the metal strip is gradually bent into the desired profile through a series of rolling stations. The entire process is highly automated, ensuring productivity and profile accuracy, and the Suspended Ceiling Channel Rolling Forming Machine is capable of producing a wide range of ceiling framing profiles, such as furring channel, wall angle, u-shaped profile for a wide range of applications in the construction industry.

Technical Specification

| Raw Material | Gi Strip |

| Coil Thickness | 0.4MM-0.8MM |

| Working Speed | 100M/Min |

| Shearing Accuracy | ±1.0MM |

| Roll Forming Main Motor Power | 5.5KW |

| Power Supply | AC380V,50HZ |

| Total Power | According Actual Design |

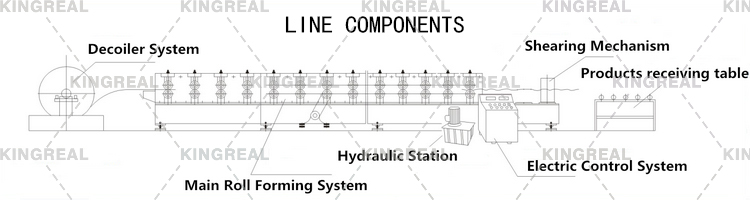

Working Process

Hydraulic Decoiler -- Continuously Roll Forming Machine -- Follow Shearing -- Product Output

Machine Featured

1. Highly efficient production: capable of ceiling channel roll forming machine in a wide range of sizes and shapes in rapid succession. (100M/Min)

2. High accuracy: through precise roll forming technology, it ensures that the size and shape of the profiles meet strict standards. (±1.0MM)

3. High degree of automation: most of the false ceiling channel making machinemachines are equipped with automated control systems to reduce manual operations and increase production efficiency.

4. Versatility: some ceiling channel machines are capable of producing multiple types of ceiling frames, such as linear, U-channel, and cap beams.

5. Compact: Designed with space utilization in mind, making the suspended ceiling channel machine footprint small and easy to install and maintain.

6. Easy to operate: user-friendly interface and operating system make the gypsum false ceiling channel gypsum steel channel machine operation more simple and intuitive.

7. Low maintenance cost: thanks to the advanced design and high quality materials, the maintenance cost of the machine is relatively low.

8. Adaptable: capable of handling metal strips of different materials and thicknesses, adapting to variable production requirements.

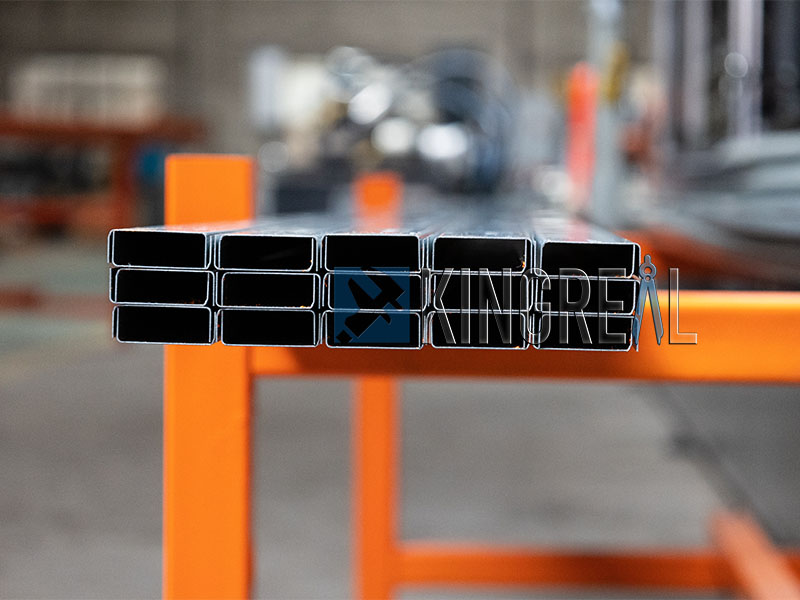

Different Metal Profile Detail

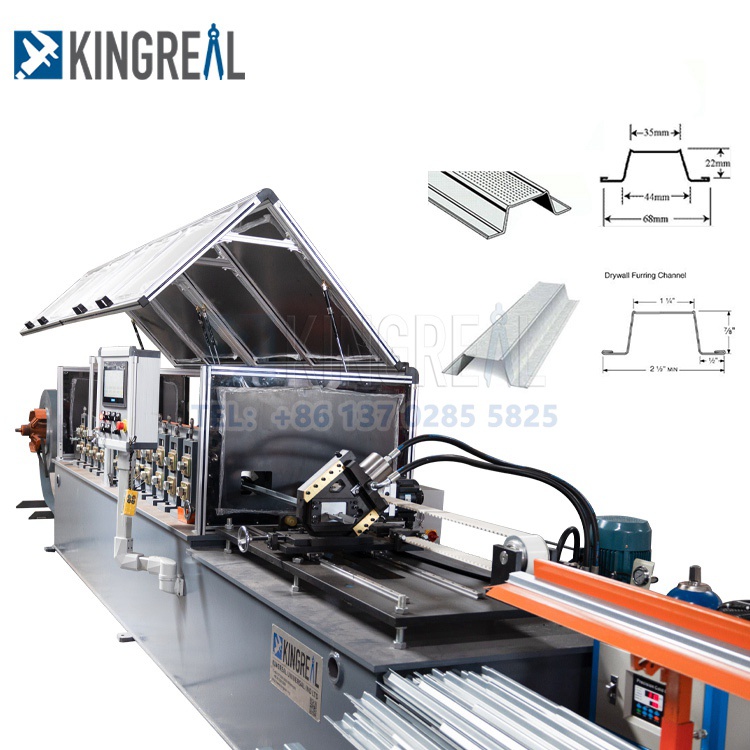

Furring Channel is a building material that is commonly used in the construction of walls and ceilings, which is produce by furring channel roll forming machine. It is a lightweight metal frame that is used to create a flat surface on a wall or ceiling to facilitate the installation of sheetrock or other types of panels.Furring Channel is especially important in suspended ceiling systems because it provides a stable foundation to hold various types of panels in place, while also helping to prevent the panels from cracking.

1. Furring Channel Machine features include:

★Lightweight: easy to handle and install due to the lightweight material.

★Versatile sizes: options are available in different depths and lengths to suit different building needs.

★High load-bearing capacity: specially designed models offer better span and load-bearing capacity for commercial applications.

★Easy to install: can be fixed directly to walls or ceilings, or hung below.

★Adaptable: can be used in a variety of building environments and designs.

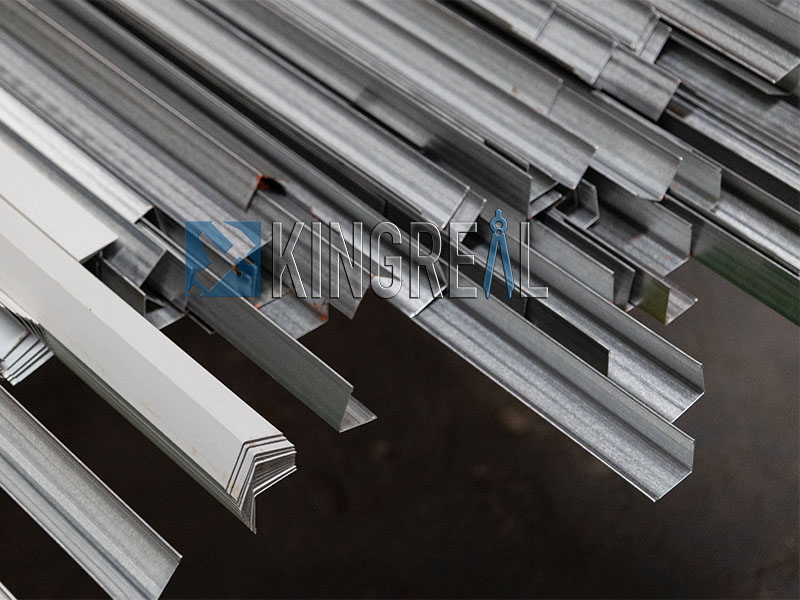

2. Wall angle profile usually refers to a metal member used in buildings to secure the edge of suspended ceiling systems, produce by wall angle roll forming machine. It is an L-shaped profile that is installed at the junction of the wall and ceiling to support the ceiling system and provide a neat visual boundary.Wall angle profile also helps to maintain horizontal and right-angle alignment of the ceiling panels to ensure a quality installation.

In suspended ceiling systems, wall angle profiles are usually used in conjunction with the main keel and sub keel to form a complete frame structure to support plasterboard or other types of ceiling panels. They are usually made of galvanized steel or aluminum for good corrosion resistance and load bearing capacity.

3. U Channel Profile is a U-shaped metal profile commonly used in construction, machine building and industry, manufacturing by u channel roll forming machine. Its U-shaped structure provides good load-bearing capacity and stability, and is commonly used for a variety of purposes including frame construction, bracing and fixing.

Features of U Channel Profile include:

★U-shaped structure: provides a stable support and connection plane.

★Multiple materials: can be made of different materials, such as stainless steel, aluminum, carbon steel, etc.

★High load capacity: The U-shaped design allows for good weight-carrying capacity.

★Easy to install: can be easily connected or welded to other structural components.

★Versatility: suitable for a wide range of industrial and architectural applications.

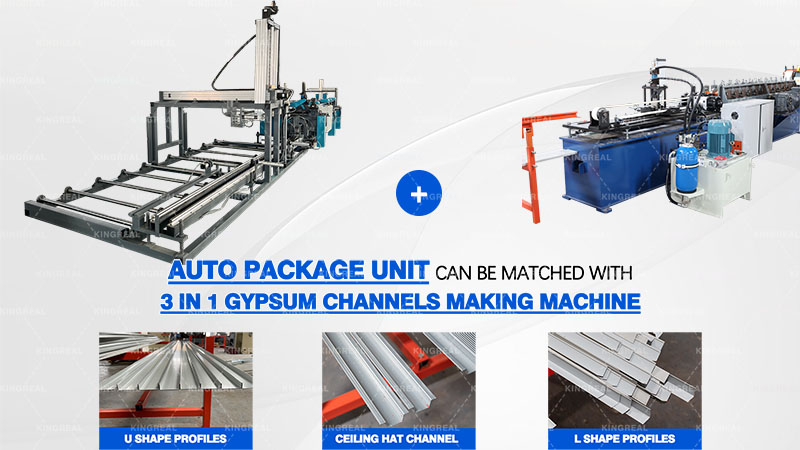

Auto Package Unit

Metal profile automatic package machine equipment is a kind of efficient automated machinery, which is specially used for producing and baling ceiling channel profile.

It has an automatic rotary hydraulic unwinder, box change roll forming machine and single shear unit packing table. Its cutting speed is 90M/min and the tolerance is 0.5mm per 1000mm. There are other types of profile automatic packaging systems, these include automatic turning systems, automatic strapping profiles, automatic stacking systems and automatic transmission systems.

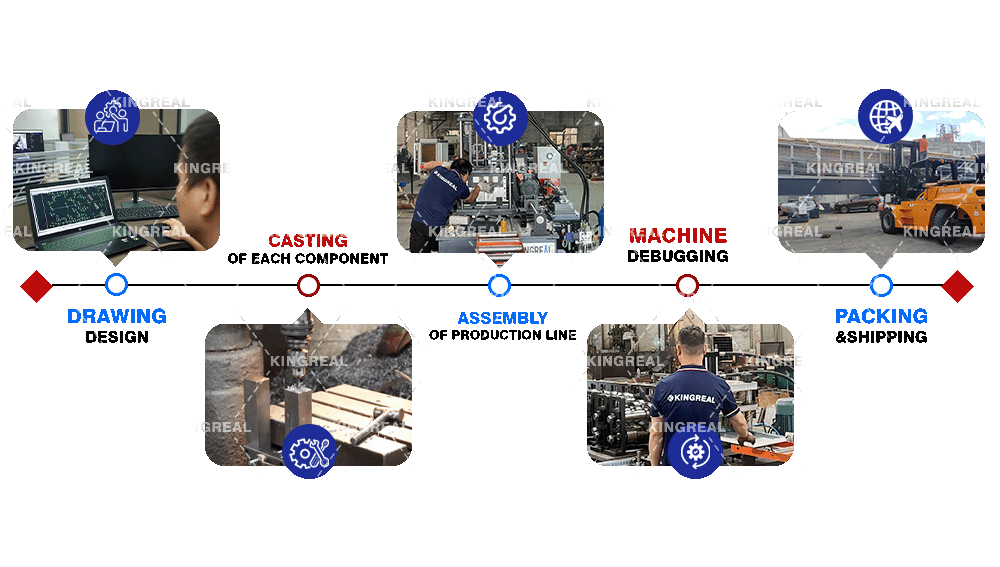

Customized Production Process

KINGREAL provides customers with a comprehensive one-stop service, covering all aspects from ceiling channel making machine design to manufacturing and subsequent trial and delivery. KINGREAL's service process ensures that each step is efficient and professional, always focusing on customer needs.

In the early stage of the project, KINGREAL's design team will work closely with customers to deeply understand their specific needs and project requirements to ensure the feasibility and innovation of the design plan. After entering the manufacturing stage, the professional production team will strictly follow the design specifications to carry out high-quality ceiling channel machine manufacturing to ensure that each aluminium ceiling channel making machine can meet the expected performance standards.

After the completion of manufacturing, KINGREAL will carry out a strict trial process, and the technical team will conduct comprehensive debugging to verify the function and performance of the ceiling channel machine. After the trial is qualified, the aluminium ceiling channel making machine will be shipped in time to ensure that customers can put it into production as soon as possible.

Throughout the process, KINGREAL will designate a dedicated person to connect with customers, maintain real-time communication, and promptly resolve customer questions and needs.

Successful Project

KINGREAL has successfully sold many channel false ceiling machines in India, Qatar, Saudi Arabia, Egypt, Turkey and other countries, and has established close cooperative relations with international customers. These successful cooperations have enabled KINGREAL to accumulate rich experience and technical advantages in the manufacturing of ceiling channel machines.

In order to continuously improve product quality and customer satisfaction, KINGREAL regularly and proactively seeks customer feedback, and on this basis conducts in-depth market research to explore the possibility of new breakthroughs and innovations. According to the actual needs of customers and market trends, KINGREAL's engineering team has upgraded the ceiling channel making machine many times and designed a variety of new models including Multi-spec ceiling channel machines ( hat shaped, u shaped and l shape ceiling channels can be produced on one production line) and channel false ceiling machines with protective shields.