Furring Channel Roll Forming Machine

Furring channel roll forming machine from Chinese manufacturer KINGREAL MACHINERY, which one of the best features is the speed can up to 120m/min.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Furring Channel Roll Forming Machine

Furring Channel Roll Forming Machine Description

High speed furring hat channel making machine is featured with high speed roll forming with follow shearing system. KINGREAL high speed furring hat channel roll forming line is made of decoiler, high precision main roll forming machine, high speed follow shearing system and material stacker. Featured with high speed, high precision and stable output, it is first choice of the decrotion materials.

KINGREAL uses high precision full servo control system for furring channel machines:

1. KINGREAL uses Yaskawa servo feeder to adjust height and width of roller sets.

2. KINGREAL uses Yaskawa servo feeder for the follow shearing system.

3. These feeders ensure high-precision,high-speed and stable operation of KINGREAL machines.

Technical Specification

Suitable Raw Material | Galvanized Steel Coils |

Coil Thickness | 0.3-0.6mm |

Coil Width | 112mm |

Quantity Of Rollers Stations | 12-14 |

Diameter Of Forming Rollers Shafts | 60mm |

Roll Forming Speed | 90-120m/min |

| Cutter Material | CR12 mould steel, with quenched treatment |

Controlling System | PLC and Converter |

Main Motor Power | 4kw |

Hydraulic Unit Motor Power | 3kw |

Features About KINGREAL Furring Channel Machine

1. Equipped With Protective Shield

With a risk index in place during production, KINGREAL high speed light steel keel roll forming machines can reach speeds of up to 120 m/min. KINGREAL has a protective hood that can be lowered during production to guarantee both the workers' and the machine's safety while it is in use.

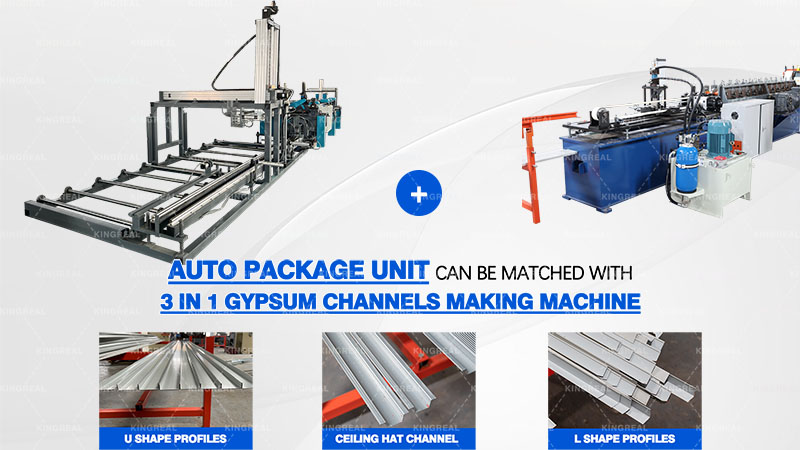

2. Supply Package Machine To Achieve Completely Automated Manufacturing

Additionally, KINGREAL specializes in automatic keel balers for shipping, stacking, and wrapping. From sheet molding to final packing, it completes the completely automated manufacturing process for keel goods, significantly increasing production efficiency and making it the factory's first option.

Quality Control In Factory

Before the hat channel machine is shipped to the customer's factory, KINGREAL has a professional team responsible for a comprehensive inspection and commissioning of the furring channel roll forming machine. This process is designed to ensure that each device perfectly meets the needs of the customer, including:

✦ Speed detection: The team carefully checks the speed of the metal furring machine to ensure that it meets the specific requirements of the customer in order to achieve efficient output during the production process.

✦ Smooth operation test: Through multiple trial runs, verify the stability of the metal furring machine under different load conditions, ensure no vibration, no abnormal sound, and provide a safe and reliable operating environment.

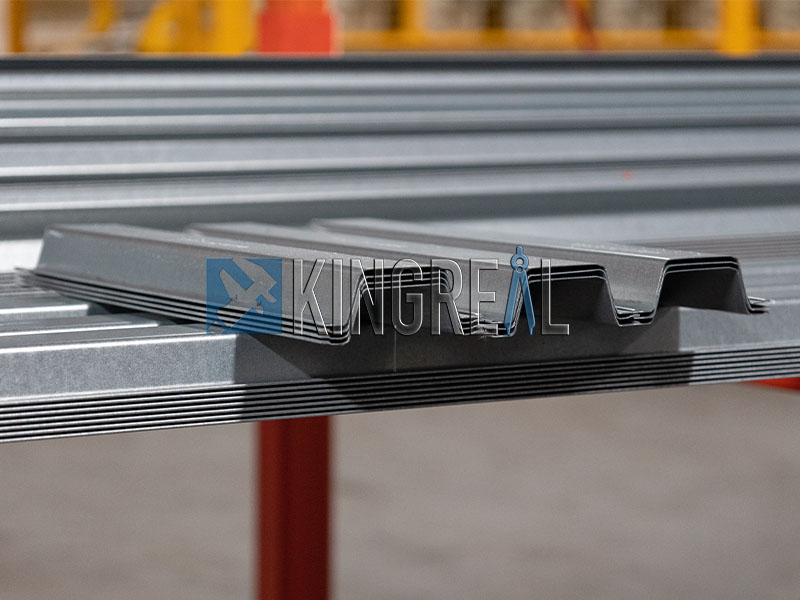

✦ Product quality inspection: The team will carry out strict quality inspection on the produced hat channel to ensure that it meets the customer's standards and requirements.

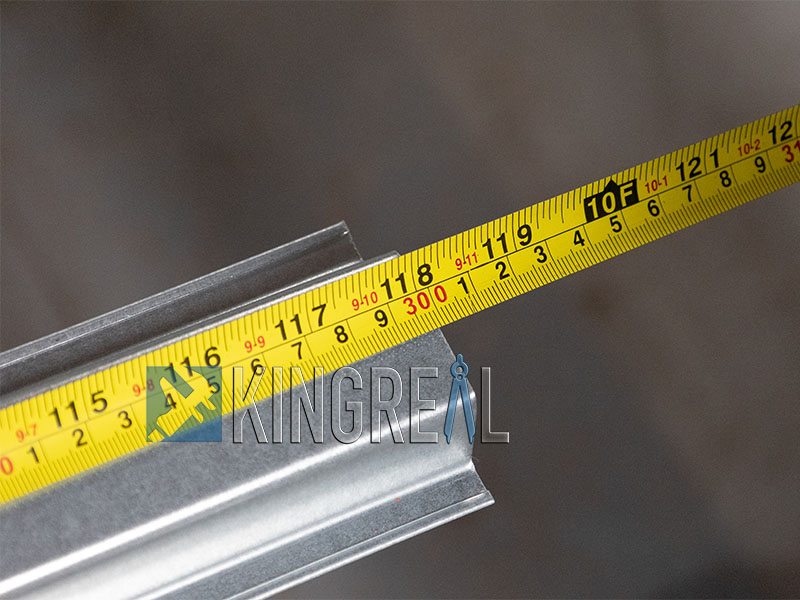

✦ Careful measurement: The staff will use professional measuring tools to carefully measure the finished product to confirm that the size of each hat channel is accurate and the surface is scratch free, ensuring that the appearance and function of the final product are of the highest standard.

This series of testing and acceptance process not only reflects KINGREAL's strict control of product quality, but also enhances customers' confidence in equipment performance. Through these measures, KINGREAL ensures that when customers receive the hat channel machine, they can immediately put it into production without worrying about the reliability of the equipment and the quality of the product.

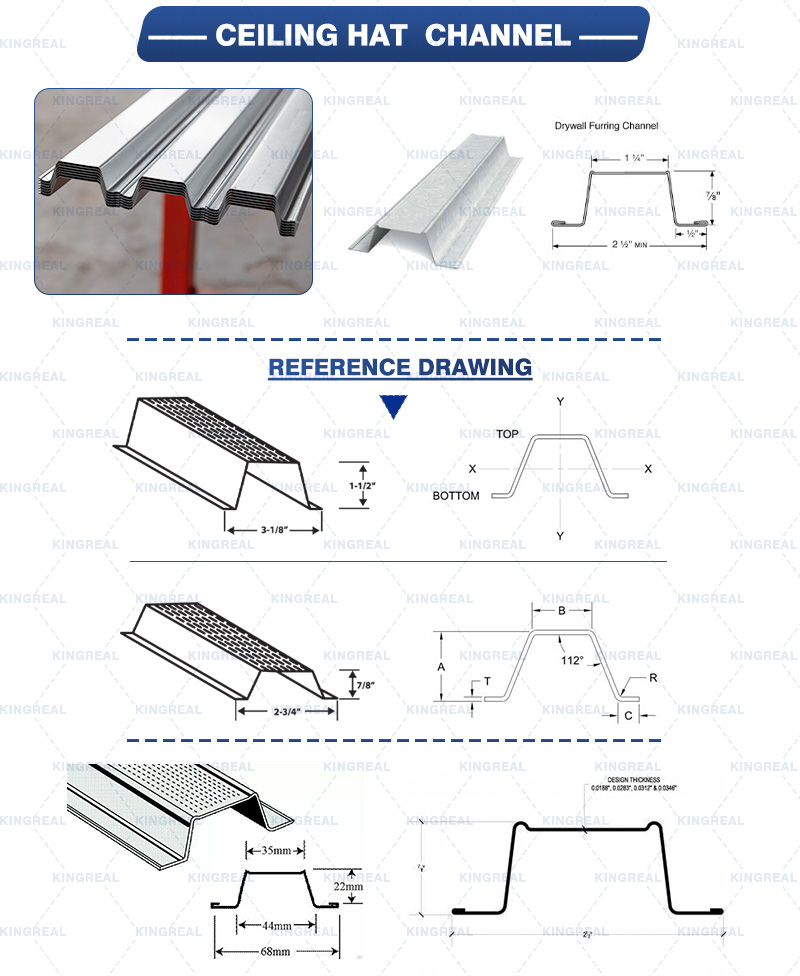

Reference Drawing Of Furring Channel

KINGREAL's furring omega making machinees can produce hat channels in different sizes. Simply provide the drawings and specific production requirements to KINGREAL engineers, who will tailor the hat channel machine according to the actual situation of the customer to ensure that the equipment can perfectly meet the various production needs. Regardless of standard size or special specifications, KINGREAL's furring omega making machines are able to complete production tasks efficiently and accurately.

In addition, KINGREAL's metal furring machines perform well during operation, enabling smooth operation and greatly reducing failure rates and downtime. The high quality of the manufacturing process ensures the durability of the equipment and the maintenance cost is relatively low, helping customers to reduce their long-term operating expenses.

Customer Visit

KINGREAL sincerely welcomes customers from all over the world who are interested in hat channel machine to visit our factory. Through in-depth workshop visits, customers will be able to fully understand the production process and technical details of the furring omega making machine. In order to ensure that customers have the best experience during the visit, KINGREAL will send professional staff to accompany customers throughout the whole process to answer questions and provide detailed explanations.

After the customer has a deeper understanding of the metal furring machine, KINGREAL will also arrange experienced engineers to have in-depth exchanges with the customer in the conference room to discuss the specific machine manufacturing solutions. This face-to-face communication not only helps the customer to fully grasp the characteristics of the equipment, but also to customize the best solution according to the actual needs of the customer.

Successful Project

Metal furring machine is KINGREAL's characteristic machine, which has been successfully sold to Saudi Arabia, India, Egypt, Turkey, UAE and many other countries. Through in-depth communication with customers in various countries, KINGREAL has accumulated rich experience in the parameter requirements of furring omega making machines in different countries and regions. This deep understanding of market needs enables KINGREAL to provide more precise equipment solutions to meet the specific needs of its customers.

In addition, KINGREAL's engineering team actively travels to factories in several customer countries to install and commission hat channel machines. They not only install the equipment on site, but also work closely with the customer to ensure that the furring omega making machines run smoothly and achieve optimal production efficiency. This practical experience gives KINGREAL engineers a solid foundation in equipment commissioning and training, and enables them to provide professional technical support to customers.