High Speed Coil Slitting Line

KINGREAL designs High Speed Coil Slitting Line to achieve slitting steel coil speeds up to 220 M/min for different materials such as steel coils, cold rolls and galvanized steel.

- KINGREAL

- China

- 100 Days

- 9999

- Information

- Download

Video About High Speed Coil Slitting Machine

Description Of High Speed Coil Slitting Machine

KINGREAL coil slitting machine is a special shearing device that processes the carbon-cold cold rolled coil and galvanized sheet by high-speed precision slitting into a required width. KINGREAL designs high-speed steel coil slitting lines to achieve slitting speeds up to 220 M/min for different materials such as steel coils, cold rolls and galvanized steel.

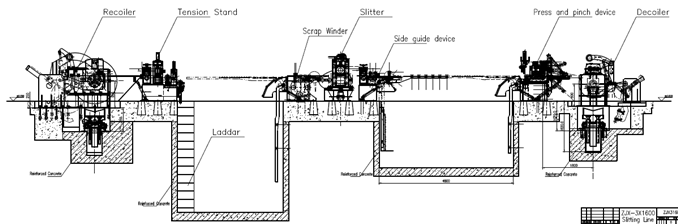

The main working machine of the high speed coil slitting line consists of four main mechanisms:

Decoiler machine, precision disc type knife seat, plate tension generating station and Recoiler machine. The middle is supplemented by conveying material, pinch leveling machine, head shearing machine and buffer. , laminating, guiding, winding waste, splitting shears, discharging and other devices.

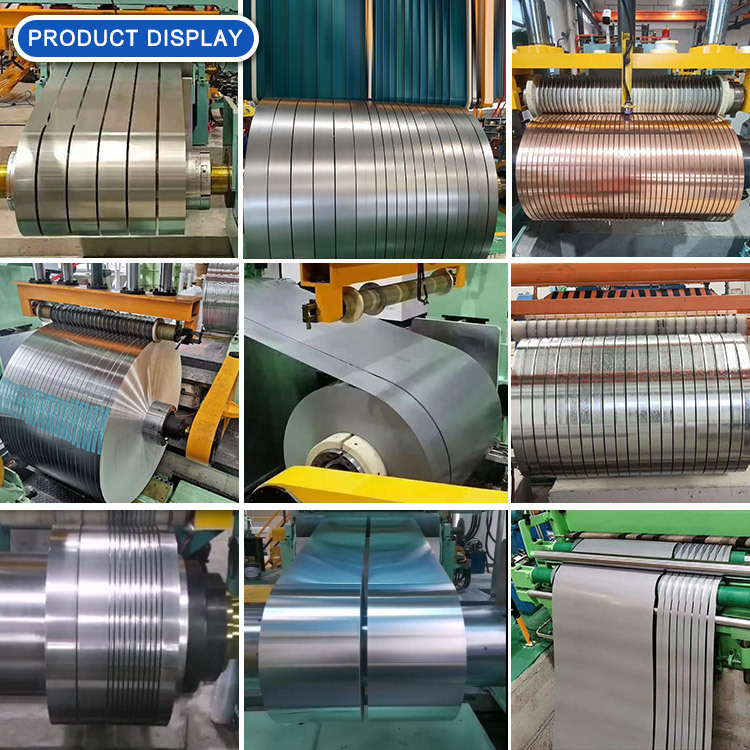

Double Slitter Head Coil Slitting Machine Display

1. Position: After the side guide device

2. Function: used to slit the coil to required width strip.

3. Structure and features: The disc shear is composed of two movable knife seat parts, power part, base and other parts.

Steel coil slitting machine is a machine that cuts strip coils longitudinally into various widths. The width of the sheared product can be flexibly changed by switching the combined spacer. Adjustment of the knife shaft adopts the lower shaft fixed, the upper shaft adjusted as a worm gear synchronous adjustment of the knife shaft spacing mode, can accurately control the gap between the upper shaft and the lower shaft. The upper and lower knife shafts adopt nuts as axial fastening, and the upper and lower knife shafts are equipped with a protective sleeve for the knife at the shaft end. The main machine adopts motorized opening and closing seat frame (motor-driven), which is convenient to replace the blade.

The main slitting line parameters

| Material of raw materials | stainless steel, cold-rolled steel |

| Raw material thickness | 0.2mm-2.0mm |

| Raw material width | 300-1550mm |

| Raw material roll inner diameter | Φ508mm |

| Raw material roll outer diameter | ≤Φ1800mm |

| Raw material volume weight | ≤12 tons |

| Slitting speed | 0-80m/min (normal working) |

| Total power | about 150KW |

| Floor area | about 18m × 6m |

Metal Slitting Machine Standard Acceptance requirements

| Strip width | 40 mm minimum |

| Finished product tolerance | subject to new knife cut:Thickness 0.2-2.0 mm=±0.03mm |

| One-sided straightness (sickle bending) | ≤0.3mm/M |

| Buttercup | ≤0.05mm |

| Production speed and cutting capacity:(subject to actual operation) | 2.0-mm can be divided into ≤ 6 (speed: 50M / Min)10 strips at 1.5 mm (speed: 60M/Min)15 points can be divided into 1.0 mm (speed: 80M/Min)20 pieces can be divided into 0.2mm (speed: 100M/Min) |

| Finished product winding inner diameter | ≥ 508 mm |

| Coiling finished product requirements | no material is received, and the receipt is neat |

| Each unit | no problem when single or continuous operation |

Coil Slitting Line Equipment Composition

| Hydraulic pallet truck | one for each feeding and discharging |

| Hydraulic uncoiler | 1 set |

| Five-bar leveling machine and head hydraulic shearing machine | 1 group |

| Looper (Bridge Bridge) | 1 group before and after |

| Guide device (ie manual side guide) | 1 group |

| Slitting host | 1 group |

| Independent waste coiler (with automatic cable) | 1 left and right |

Hydraulic tensioning machine with narrowing device | 1 set |

| Separator, hydraulic coiler | 1 set |

| Hydraulic system | 1 set |

Technical Specification Steel Coil Slitting Machine

| Material | hot rolled sheet, galvanized sheet, cold rolled sheet, stainless steel, aluminum sheet, galvanized sheet, etc. |

| Material weight | up to 10T |

| Material thickness | 0.15-0.8mm |

| Material width | ≤1550 mm |

| Discharge width | 20 mm-1550 mm, stepless |

| Tool shaft diameter | φ180 mm |

| Slitting speed | 0-180 m/min, stepless |

| Unilateral non-straightness | ≤0.1mm/m |

| Slitting width error | ±0.02 mm |

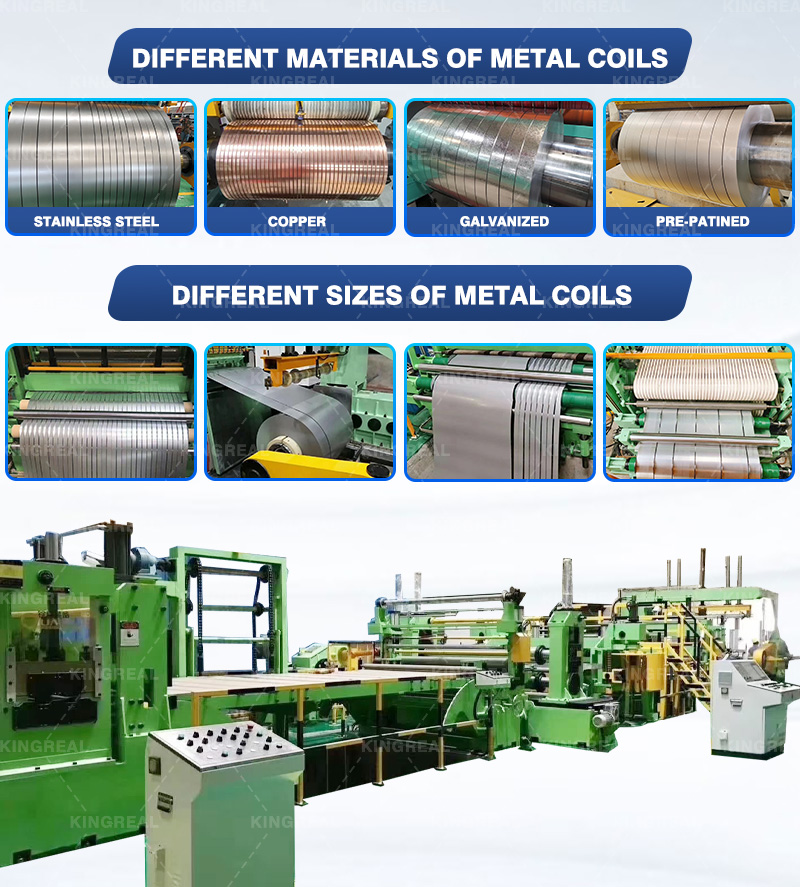

Multiple Choice for Your Coil Sliting Production

Different feed materials and different size of finished coils is optional.

KINGREAL can provide a variety of metal coil slitting machines to meet the different production needs of customers, including but not limited to:

Copper slitting machine

Aluminium coil slitting machine

Hot-rolled slitting machine

Cold-rolled slitting machine

Stainless steel slitting machine

Silicon steel slitting machine

KINGREAL Technical Team

KINGREAL is not only integrating R&D, have our own technical team and factory, but also have many years of experience in the design and manufacture of Coil Slitting Machine. We have successfully customized Coil Slitting Machine lines to meet the needs of customers in many countries.

KINGREAL has established the localized technical support team in Indonesia, Brazil, Saudi Arabia, Canada, India and etc.. Localized service points in other countries are also in progress.

Customer Visit

KINGREAL warmly welcomes customers from all over the world to visit KINGREAL's factory and experience the operation of the steel coil slitting machine in person. To ensure that the customer's visit experience is smooth and pleasant, KINGREAL will provide professional pick-up and drop-off services and accompany customers throughout the visit.

During the visit, KINGREAL's staff will lead customers into the workshop to witness the efficient operation of the metal slitting machine. Customers will observe the performance of the steel slitting machine on site and measure the finished narrow strips.

After understanding KINGREAL's metal slitting machine, KINGREAL will invite customers to the conference room for more in-depth exchanges. KINGREAL's professional engineers will communicate with customers in detail to understand their specific needs and provide tailor-made steel slitting machine solutions. Through this interaction, KINGREAL hopes to ensure that every customer gets the best equipment that meets their production requirements.