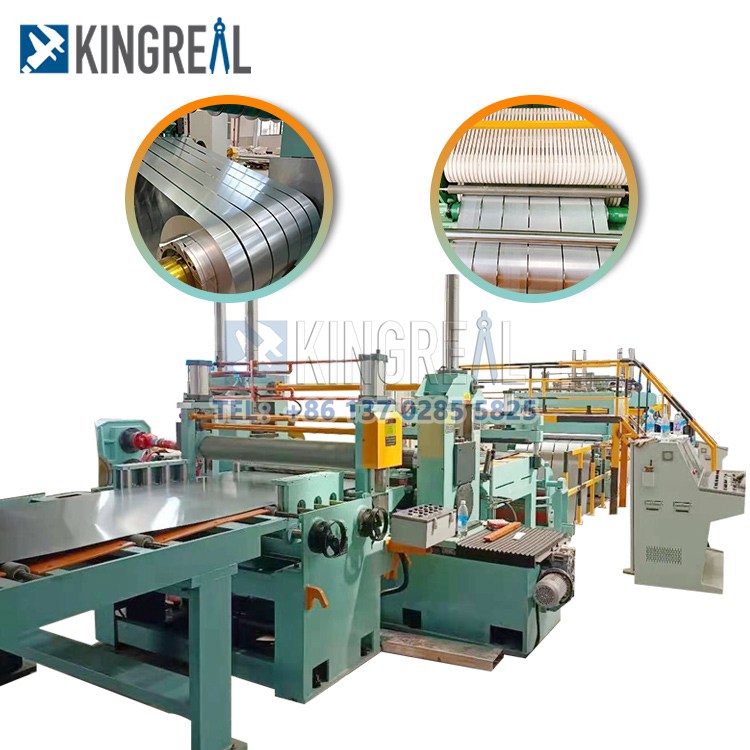

Steel Coil Slitting Line

KINGREAL high speed series disc Steel Coil Slitting line - Thin steel Sheet is a continuous production line consisting of uncoiler, pinch initial correction, main coil slitting machine and recoiler.

- KINGREAL

- China

- 100 Days

- 9999

- Information

- Download

KINGREAL Steel Coil Slitting Machine Video

KINGREAL Steel Coil Slitting Machine Video

KINGREAL Coil Slitting Machine Successful Cases in Global

Years of penetration into the Metal Sheet Slitting Machine equipment market, KINGREAL have successfully stocked many successful cases and localized technical support experience:

1. Double Slitter Head Slitting Machine

2. Heavy Gauge Slitting Line

3. Silicon Slitting Machine

4. Narrow Strip Coil Slitting Machine

5. High Speed Coil Slitting Line

And so on...

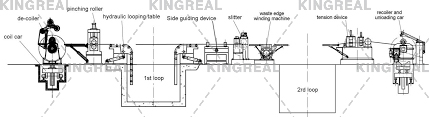

Basic Procedure Of The Thin Sheet Steel Coil Slitting Line

KINGREAL Steel slitting machine is a kind of mechanical equipment used for cutting and slitting metal materials into strips. It mainly consists of loading trolley, uncoiler, leveler, slitter, waste edge winder, tensioner, winder and unloading device. These equipments work in concert to slit wide metal or non-metal coils into precise narrow web strips. The coil is hoisted from the coil store to the coil preparation device, and then sent to the uncoiler drum by the steel coil trolley. The coil is opened to fix the coil on the reel, the strap is removed, and the unwinding device is used.

The lead is introduced into the pinch device, through the side guide of the looper, the disc is cut and cut (trimmed), the edge wire is collected by the edge machine, and the strip is fed through the looper and the tension table. The winding jaws can be produced in conjunction with the belt.

Technical Specification Of High Speed Coil Slitting Line

1. Equipment Technical Data

| Applicable materials | cold rolled plate, color plate, galvanized plate, pickled roll |

| Material quality | domestically produced genuine steel or international standard steel |

| Tensile strength | δb≤450Mpa, δS≤260Mpa |

| Material thickness | 0.5-3mm |

| Material width | 600-1600 (Max) |

| Steel coil inner diameter | φ470-520 |

| Steel coil outer diameter | φ1600mm (Max) |

| Coil weight | 15T (Max) |

| Vertical scissors shaft diameter | φ200 Material: 40Cr |

| Vertical scissors | φ200Xφ340X20 |

| Vertical scissors material | 6CrW2Si |

| Maximum number of branches | 30 |

2. Finished slitted product parameters:

| Width accuracy | ≤ ± 0.05mm |

| Other parameters of the equipment | / |

| Power | 380V/50Hz/3Ph |

| Line speed | 0-120m/min |

| Installed capacity | 200 Kw |

| Production line area (approx.) | length 28mX width 8m |

| Production operators | 1 skilled worker and 2 general workers |

| Production line direction | from right to left (the console is facing the unit) |

| Equipment color | white gray |

3. The Coil Slitting Machine Composition

■Hydraulic loading trolley ■Hydraulic expansion and discharge rack ■Pinch and leveling mechanism ■Hydraulic cross cutting machine ■Small heavy head ■Storage looper I ■ Lateral positioning device ■ slitting host ■Receiving waste wire device ■Storage Looper II ■Pre-separation tension damping device ■Hydraulic fixed length shear ■Hydraulic winding host ■Hydraulic unloading trolley ■Hydraulic control system ■Electronic control system |  |

Features And Process For The KINGREAL High Speed Coil Slitting Machine

1. KINGREAL high speed series high-speed precision slitting and slitting unit adopts programmable design, which automatically switches the working mode of the production line according to the nature of the plate, which can obviously improve the production efficiency and reduce the maintenance frequency. 2. The expansion and contraction hydraulic cylinder of the hanging material unwinding machine and the winding machine adopts one-piece design, and the failure rate is low. |  |

3. The high-efficiency disc tension brake combination is arranged on the main shaft of the uncoiler, slitting main machine and winder, which is adjusted by the air pressure circuit, and automatically brakes the brakes under certain conditions to avoid the looseness of the steel coil. Take off. 4. The pinch feeder actively feeds and can automatically run synchronously with the production line. 5. The slitting main machine adopts the integrated base and the separate transmission structure, which can effectively improve the rigidity of the mechanical structure, reduce the vibration amplitude of the longitudinal scissors and improve the quality of the finished product. |  |

6. The vertical plane shear axis reference plane amplitude accuracy is within 0.006mm, which can better extend the tool life and ensure the precision of the finished product. 7. The crimping wire adopts tension type winding and is equipped with a slip structure, which can effectively improve the stability of mechanical operation. 8. The direct pressure type tension damping structure adopts the wool felt with good elasticity and high wear resistance coefficient as the fabric to ensure smooth operation during the production of the equipment; in addition, it is equipped with a pressure balance device to balance the pressure on both sides of the pressure receiving surface. |  |

Separate press mechanism adopts hydraulically configurable back pressure combination to stabilize the pressure, automatically rises as the coil diameter increases, and always effectively presses the coil. The self-tension design of the finished product winding can improve the tightness of the finished product winding.

Process Flow And Characteristics Overview

The steel coil is transported from the steel coil warehouse to the steel coil preparation device, and then sent to the unwinder reel by the steel coil trolley. The reel is opened to fix the steel coil on the reel, and the bundle is removed. With the unwinding device, the belt is introduced into the pinching device, conveyed to the coarse correction, through the side guide centering, strip cutting (cutting), looping, tension winding, and cutting. 2) Adaptable materials: cold rolling, electro-galvanizing, hot-dip galvanizing, aluminum-zinc plating, electrical steel, coated plate, stainless steel.

Another Features of kingreal steel coil slitting line

In order to ensure the long-term stability of product performance, the key components of this equipment are imported products such as bearings, blades, cutter shafts, and receiving reels. The domestic processing and procurement parts adopt the highest technical standards among domestic counterparts.

a. Automatic feeding centering function;

b. The unwinding function assisted by the trolley;

c. Ultrasonic detection unwinding tension automatic control system;

d. Unwinding reel prevents inner ring crease function;

e. The movable platform lifts the convenient board and the automatic tailing function;

f. Hydraulic lock knife and knife shaft anti-jump function; line out knife, test knife;

g. The side wire collects the function; the fine side wire does not stop the winding function;

h. Constant tension winding function;

i. Automatic positioning function of the winding jaws;

j. fixed length slitting function;

k. Full-line linkage single operation;

How To Ensure The Quality Of Steel Slitting Machines

As a professional manufacturer of metal coil slitting machines in China, KINGREAL is committed to providing customers with high-quality metal coil slitting machines. From the procurement of raw materials, precision casting of components to the assembly and commissioning of the steel coil slitting machine in the factory, a series of quality inspection processes are carried out to achieve high-quality coil processing and production effects, helping customers improve production efficiency and quality.

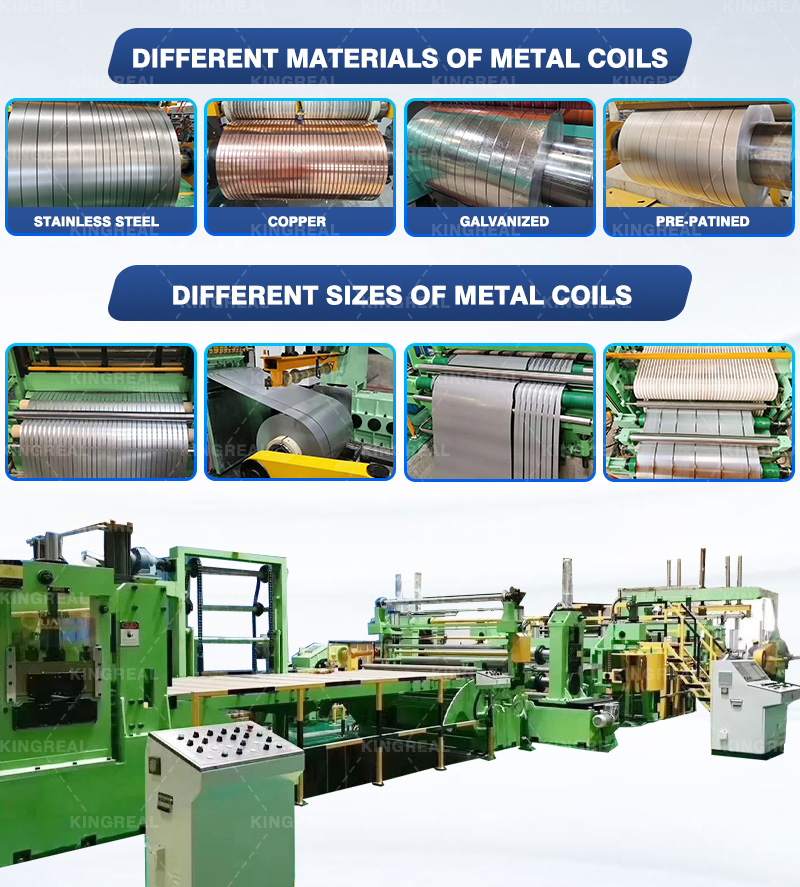

Final Coil Slit Product Display

KINGREAL can provide customers with various coil slitting machine solutions, whether customers need stainless steel slitting machines, copper slitting machines, galvanized slitting machines, aluminum slitting machines, hot-rolled slitting machines, cold-rolled slitting machines, etc., KINGREAL can provide the corresponding metal slitting machines. And KINGREAL's coil slitting machines can slit narrow strips of different widths for metal coils according to customer needs.

Customer's Feedback in Saudi Arabia

KINGREAL will regularly visit customers who have purchased KINGREAL coil slitting machines to inquire about the recent use of the coil slitter and whether there are any optimization suggestions for KINGREAL coil slitting machines. Recently, KINGREAL staff received good comments from a Saudi Arabian customer, who said that KINGREAL's coil slitting equipment are of good quality, very durable, low maintenance costs, and fast slitting speed, which greatly improves production efficiency.