High Speed Cut To Length Line

KINGREAL High Speed Cut to Length Line process is controlled by PLC, intelligent one-button start and stop, simple operation, stable operation, high production efficiency, neat stacking, suitable for mass production, which speed can up to 80m/mim

- KINGREAL

- China

- 120 Days

- 9999

- Information

- Download

Video About Fly Shearing Cut To Length Line

Description Of Cut To Length Line

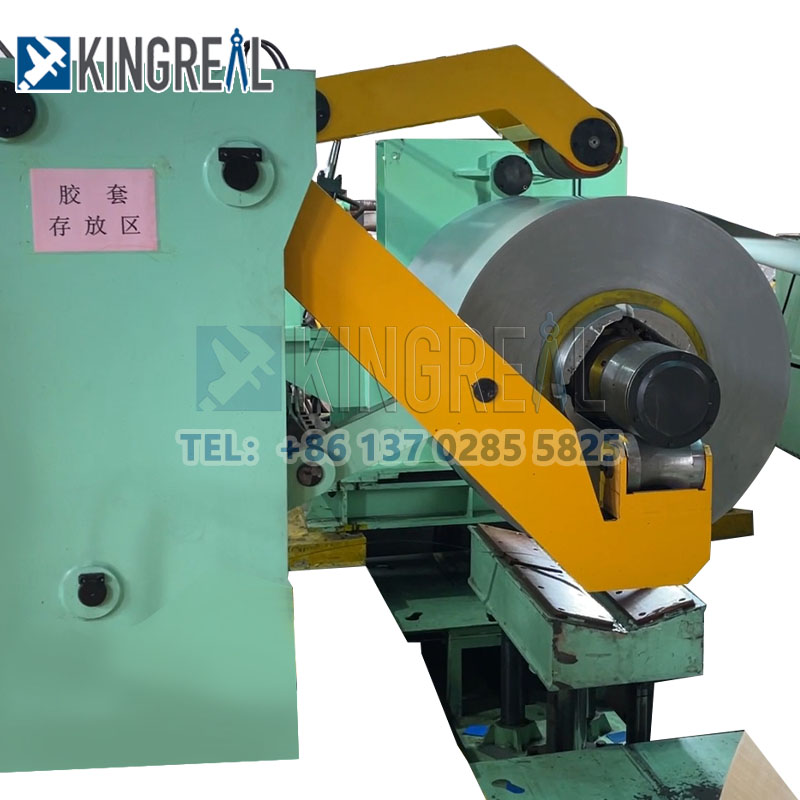

KINGREAL High Speed Cut To Length Line is used to unwind, level, cut and cut the metal coil into a flat sheet of the required length and stack it. The production line mainly consists of loading car, unwinding machine, leveling machine, feeding mechanism, flying shear, conveying device, stacking device and discharging device. It is a high-performance product integrating machine, electricity and liquid.

The steel plate is started with one button start, and the flying shear cutting process follows the steel plate forward, and the steel plate is cut at the same time, so that the reciprocating circulating steel plate does not stop the feeding work. The whole process is controlled by PLC, intelligent one-button start and stop, simple operation, stable operation, high production efficiency, neat stacking, suitable for mass production.

Main composition of cut to length line machine

Uncoiler, leveling machine, looper bridge, centering device, flying shear, belt conveyor, first receiver, second receiver, discharge device, loading trolley, looper, first Lifting platform, second lifting platform, cable trench, electric control cabinet, cable trench, hydraulic station, hydraulic station, 1# console, 2# console, 3# console

Techncial Specification

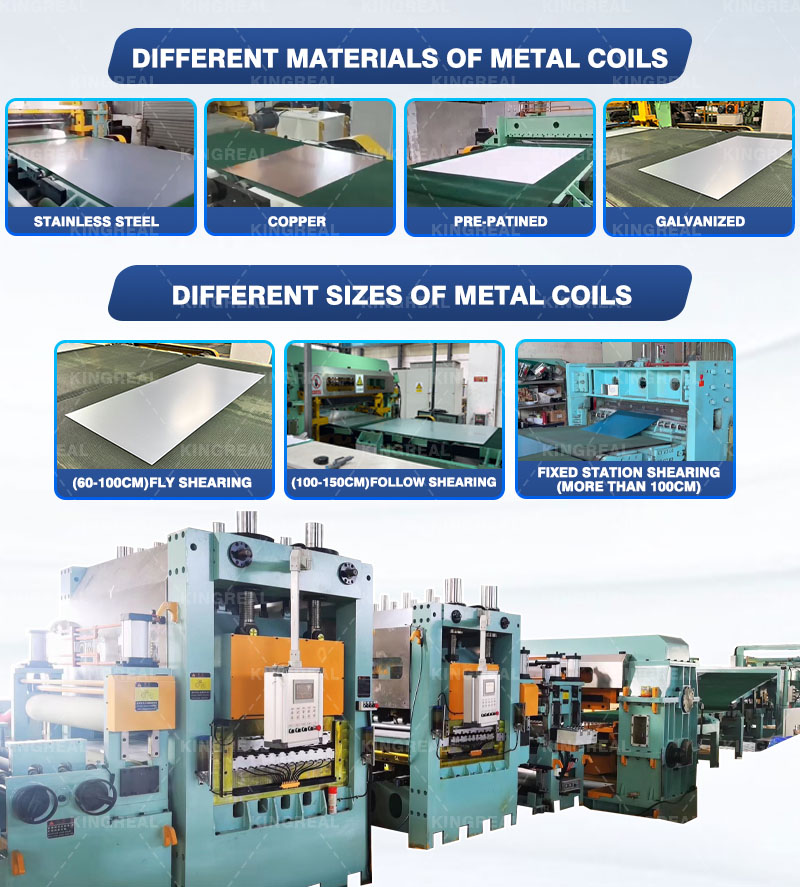

1. Raw Material : CR Steel/Aluminum/Copper

2. Coil Thickness : 0.4-3MM

3. Width : 1500MM

4. Coil OD : ≤Φ1800mm

5. Coil ID : Φ508mm、Φ610mm

6. Coil Weight : 20T

7. Length : 500-6000MM

8. Speed : 80M/Min

Main Components Detail

1. Hydraulic Decoiler An essential component of a metal shearing line, a hydraulic decoiler is used primarily to unroll and direct metal coils to shearing or other processing machinery. Supporting Coil: Assists in maintaining the stability of the coil by tightening its bore. Maintaining strip tension while smoothly unwinding the strip is known as strip unwinding. |  |

2. Fly Shearing Equipment Main components are the electric part, pneumatic clutch, blade, and main frame. - Main frame: Premium carbon structural steel is welded throughout, and after welding, it is annealed. - Blade: The four-sided cutting edge of the Cr12 material blade is replaceable, and it has undergone heat treatment to a hardness of HRC62. |  |

3. Equipment for Auto Stacking |  |

Applicable materials

Cold rolled sheet, electrolytic galvanized sheet, hot dip galvanized sheet, color coated sheet, stainless steel sheet, aluminum sheet, copper sheet, etc.

About Us

KINGREAL is one of the most professional coil processing equipment manufacturers in China. Its main coil processing equipment includes slitting machines and cut-to-length lines, and also provides customized coil solutions for other industries. KINGREAL has engineers and technicians with extensive expertise to meet various customer needs, as well as its own processing plant to produce high quality machines.