Metal Cut To Length Production Line

KINGREAL Metal Cut To Length Machine is made to shear metal coils with varying thicknesses into sheets (0.3-3MM) with a predetermined width so that they can be processed. further.

Contact us for a current quote!

- KINGREAL

- China

- 100 Days

- 9999

- Information

- Download

Metal Cut To Length Line Video

Metal Cut To Length Line Description

KINGREAL Metal Cut To Length Line is hydraulic drived, full automatic,high precision equipment set can produce different type of steel coil such as aluminum ,color steel ,stainless steel and etc.

KINGREAL Feature Coil Process Equipment:

1. Double Slitter Head Slitting Machine

2. Heavy Duty Coil Slitting Machine

3. Stainless Steel Cut To Length Line

4. Cut To length Line With Fly shearing

5. Light Gauge Cut To Length Machine

6. Medium Gauge Cut To Length Machine

7. Heavy Gauge Cut To Length Machine

CTL Line Mechanical Characteristics

| Including coil loading car, hydraulic decoiler, looping pit table,slitter, scraps rewinder, looping pit table ,tension station,recoiler, transport trolley ,hydraulic system,electric control system. For processing manufacture, hot-rolled plate, carbon steel, stainless steel, aluminum and other non-ferrous metals. |  |

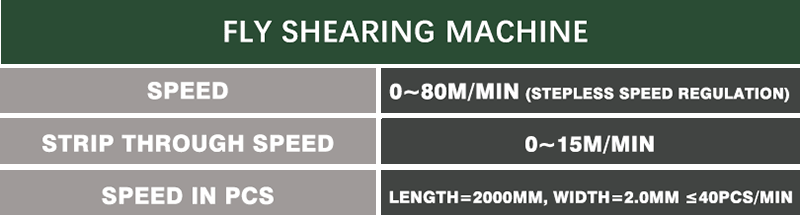

Cut To Length LineTechnical Specification

●Material width: 800-1600mm

●Material thickness: 0.3-2.2mm

●Products sizes: As per requirements

●Automation: Manual Operation/Full-Automatic Production with PLC

●Certificate: CE certificate, ISO 9001 certificate

●Machine Power: 380V 50HZ or according with customers‘ request

●Speed: 0-100 m/min

●AIR Supply: 5 kg/cm2

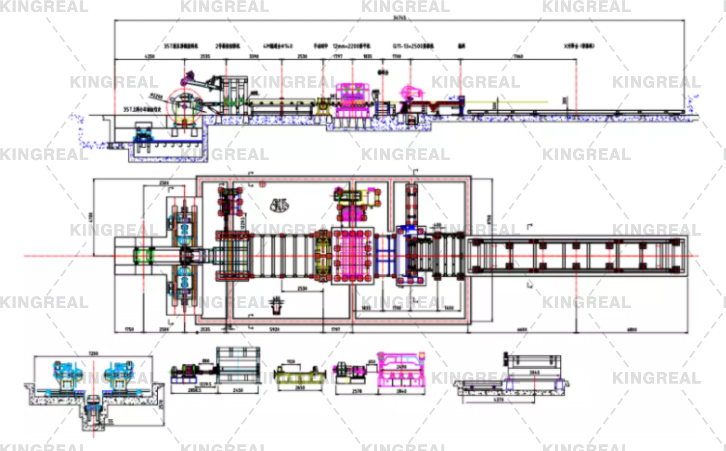

Workflow Of KINGREAL Metal Cut To Length Machine

Hydraulic Decoiler → Pinch feed roller feeding → High precision leveling device → Fixed length cutting → Unloading table / Automatic stacking table

Main Components Detail

1. Decoiler With Hydraulic Cantilever, Number One

The maximum capacity of the KINGREAL hydraulic cantilever for uncoiling and supporting coils is 15 tons.

The uncoiler is retractable and suited for the coil inside diameter thanks to hydraulic cylinders. It has a cantilever arm attached.

2. Highly Accurate Leveling Equipment

For high speed feed and exact length control adjustment, the KINGREAL leveling machine is driven by a servo motor. Programmable control is used to operate the control console.

Drive system: synchronized conveyor belt to feed rollers, 15KW servo motor, precision reduction drive

3. High-speed shearing device

Cutting modes include automatic direct signal feeder shears and hydraulic up-and-down shears. 2mm can be safely sheared using gap adjustment design, cutting materials, and heat treatment.

Cut To Length Line Product Display

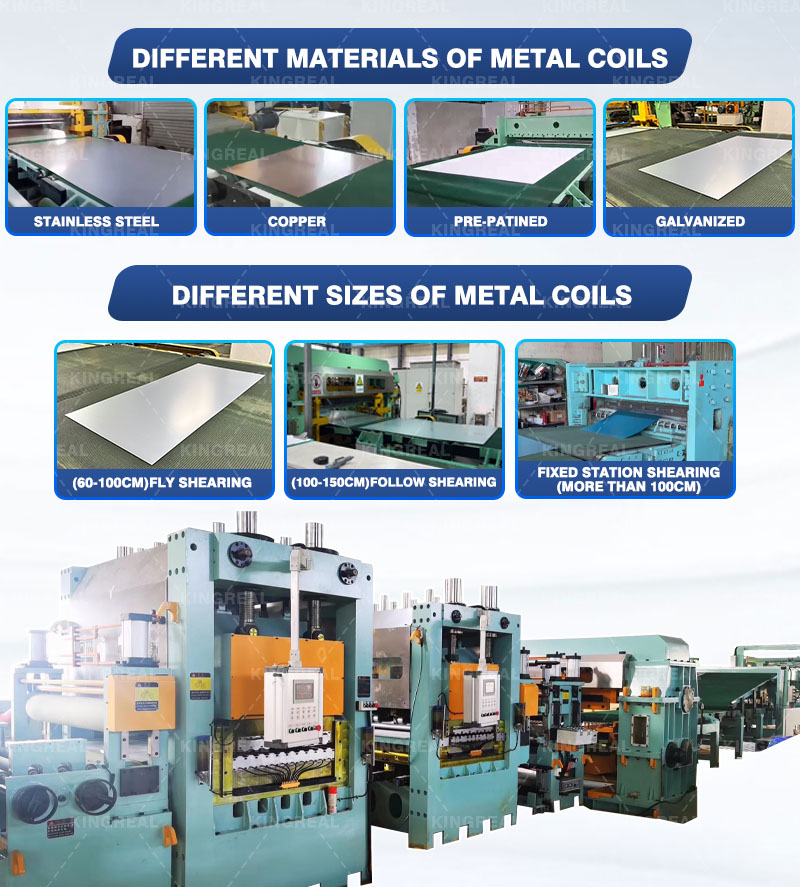

KINGREAL metal cut to length line can process a variety of metal raw materials such as copper, stainless steel, aluminum, galvanized, etc., and according to the different production needs of customers, KINGREAL has designed three metal cut to length lines with different shearing methods, namely, following cut to length line, fixed shearing cut to length line and flying shearing cut to length line.

KINGREAL's metal cut to length line has high precision and can shear high-quality sheets without burrs, with an error range of ±0.1mm.

Customer Feedback From Russia

A customer from Russia recently spoke highly of KINGREAL's fully automated metal cut to length line. He said that the outstanding performance of KINGREAL's metal cut to length line not only significantly improved production efficiency, but also effectively reduced labor costs, bringing significant economic benefits to his production operations.

The customer also mentioned that KINGREAL's metal cut to length line maintains excellent shearing accuracy while ensuring high efficiency. This high-precision processing capability enables the produced metal sheets to meet industry standards.

FAQ

1. Are you a manufacturer?

Yes, KINGREAL Machinery is a professional sheet metal processing machines manufacturer, we are an OEM.

We have been focusing on the field of machine manufacturing for more than 20 years.

2. How to visit your factory?

There are 2 ways: either by plane or by train to Foshan/Guangzhou port. We will be picking you up in plane/train station, then we can go together.

3. What‘s your Install and Training ?

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, Manual book and video is provided to show how to install and operate.