Light Gauge Steel Framing Machine

KINGREAL Light Gauge Steel Framing Machine using professional-grade industrial computer CNC automatic control, which has the characteristics of high product accuracy, high degree of automation and high degree of automation. We have successfully shipped to Saudi Arabia and Russia, etc.

Welcome to contact us!

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video Display About Light Steel Framing Machine

Light Gauge Steel Frame Machine Description

KINGREAL Light Gauge Steel Framing Making Machine is composed of MAKER LGS production control software, and the molding machine, which comprises three steps of stamping and forming and cutting, the production method of the front punching shear.

The features of light steel frame roll forming machine is that has their own design of production control software, to achieve the best results. With independent intellectual property rights LGS framing machine production control software can insure the system be used in all kinds of working environment with its industrial grade computer.

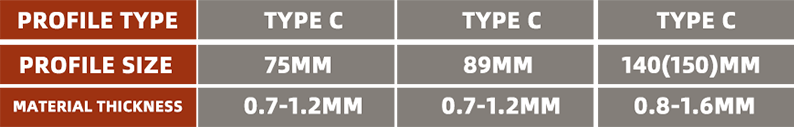

Technical Specification Of Light Gauge Framing Machine

| Section sizes | 89*41mm |

| Raw materials thickness | 0.7-1.2mm (G300-G550) GI materials strip, Aluzinc materials strip |

| Raw materials width | 181mm |

| Standard production speed | 350-900m/h |

| Max. Production speed | 1600m/h |

| Hydraulic system power | 7.5kw |

| Hydraulic oil capacity | 300L |

| Main machine remote control | Wireless remote control equipped |

| Punching molds | dimple hole, Chamfer cut, Web notch, lip cut, service hole, bolt hole and shearing |

| Machine Dimension | 5200*1100*1660mm |

| Machine weight | 5500KG |

| Decoiler | Max. load 2000KG, automatic hydraulic expension |

Main roll forming machine power | High precision 7.5kw servo motor |

Components Of LGS Roll Forming Machine

- Decoiler - Material leveling device - Main roll forming machine - Automatic punching - Cutting - Products collecting table - Control cabinet |  |

Unique Custom Design For Light Steel Frame Machine

Hydraulic Decoiler Auto hydraulic expansion design, the material inner diameter 460-520mm, external diameter maximum 1400mm, maximum loading weight 2000kgs, automatic decoiler straightener with VFD speed setting. And the power is 4KW. |  |

Copra Software Design The forming rollers of the LGS framing channel making machine is designed and simulated by Copra software. Then it is improved according with KINGREAL's experiences. |  |

High Quality Punching Stations The punching molds of the LCG framing house is specially designed with high quality S45C materials as the molds base. And D2 high quality mold steel for the blade. The auto lubrication system is equipped to ensure the machine long time stable running. |

|

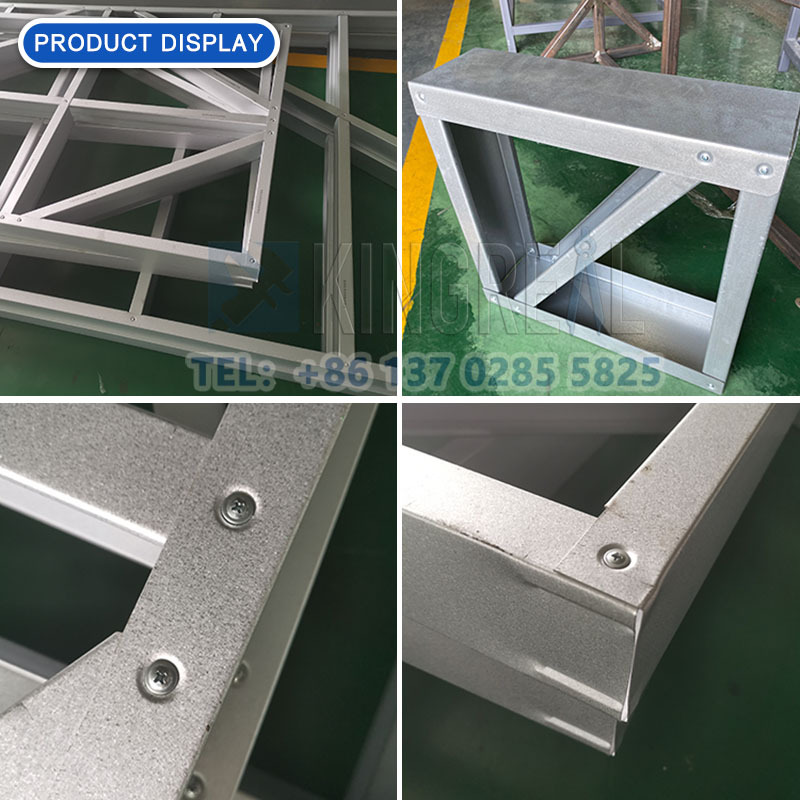

Light Gauge Steel Framing Display

KINGREAL's light gauge steel framing machines are capable of producing various types and sizes of LGS frames, and one lgs framing making machine can efficiently process metal raw materials of different thicknesses to meet the diverse needs of customers.

KINGREAL has a strict light steel framing machine manufacturing process, which is very strict from the beginning of raw material selection. Each batch of raw materials undergoes strict testing to ensure that its quality meets KINGREAL's standards. During the machine manufacturing stage, KINGREAL will also have a professional team to supervise the whole process to ensure that every link meets strict quality control requirements. Customers have given high praise to KINGREAL's lgs steel framing machines, and generally believe that KINGREAL's lgs steel forming machines are of excellent quality, produce high-precision lgs frames, and have low maintenance costs.

Application Of Light Gauge Steel Framing

Light steel structure is a young and very vital steel structure system. has been widely used in general industrial and agricultural, commercial and service buildings, the such as offices, villas, warehouses, stadiums, entertainment, tourism buildings and low and multi-story residential buildings, etc.

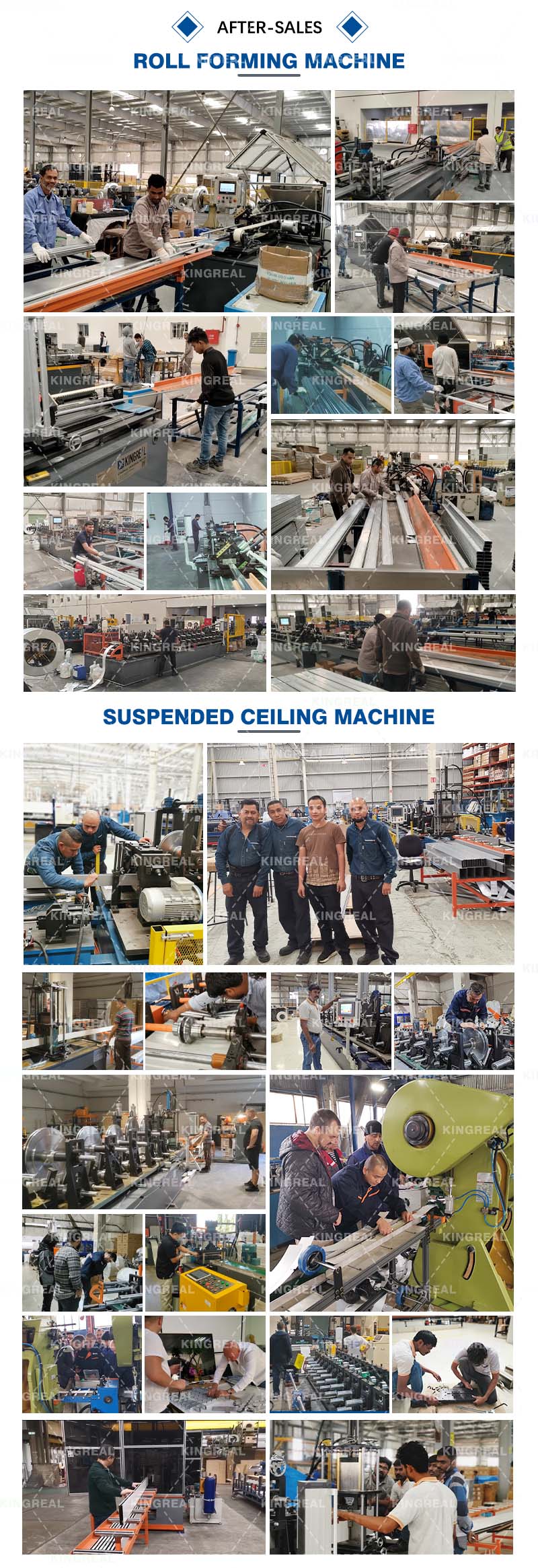

KINGREAL After Sale Service

As one of the professional manufacturers of roll forming machines in China, KINGREAL has its own production workshop and technical team. KINGREAL is able to provide our customers with the most professional production and after-sales service. KINGREAL can provide both online and offline after-sales service for KINGREAL customers. KINGREAL is available 7*24x hours online to answer customers‘ questions. At the same time, KINGREAL will arrange engineers to go to customer‘s factory for installation and technical guidance service.

KINGREAL are looking forward to cooperating with customers from all over the world, welcome to contact us.

Customer Visit

KINGREAL warmly welcomes customers from all over the world to visit KINGREAL's factory for inspection. In order to ensure that every customer can get the best experience, KINGREAL has equipped professional staff to accompany the visit of light gauge steel framing machines throughout the whole process.

During the factory visit, many customers expressed high satisfaction with KINGREAL's service. KINGREAL will lead customers to the test workshop of light gauge framing machines and introduce the main components of lgs framing making machine and their respective functions in detail. Customers can not only see the actual operation of the lgs steel framing machine, but also personally participate in measuring the precision of the lgs frame. The reason why KINGREAL can provide such a detailed factory visit service is due to KINGREAL's confidence and persistent pursuit of its own products. KINGREAL has always been committed to providing customers with high-quality equipment and high-quality services, so that every customer can have a deeper understanding and recognition of KINGREAL's products. Looking forward to your arrival and witnessing KINGREAL's excellent quality with KINGREAL!