Light Steel Villa Structure Roll Forming Machine

KINGREAL Light Steel Villa Structure Roll Forming Machine is for produce the steel structure of the light steel villa house, which maximum speed up to 1000mm per second for light steel components.

As a professional manufacturer, KINGREAL can customize and design different LGS roll forming machines according to customers‘ relevant requirements and product drawings, welcome to contact us.

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video Display

Description Of LGS Roll Forming Machine

KINGREAL Light Steel Villa Structure Roll Forming Machine is for production of the steel structure of the light steel villa house, which maximum speed up to 1000mm per second for light steel components.

KINGREAL Light Gauge Steel Roll Forming Machine consists of automatic material decoiler, material leveling device, main roll forming machine, automatic punching, cutting, products collecting table and control cabinet. According to the specific requirements of light steel villa construction, it is equipped with: dimple screw holes, chamfer, web through holes, small edge cutting, pipeline holes, web shrinking, cutting and other punching dies and coding devices.

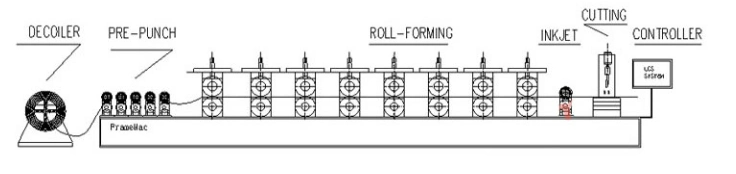

Working Process Drawing Of Light Steel Villa Structure Machine

Decoiler -- Pre-punch -- Roll forming -- Inkjet -- Cutting --Controller

Technical Specification

| Products Name | C-Shaped LGS Frames |

| Products sizes | C75, C89, etc |

| Automation | Manual Operation/Full-Automatic Production with PLC |

| Machine Power | 380V 50HZ or according with customers‘ request |

| Speed | 900m/h, Hydraulic Shearing System |

| Decoiler | Auto with Servo Motor ; Power - 1.5 Kw ; Max load 2 Tons |

| Main Unit Power | 7.5KW |

| Hydraulic Power | 5.5KW |

| Equipment Total Power | 14KW |

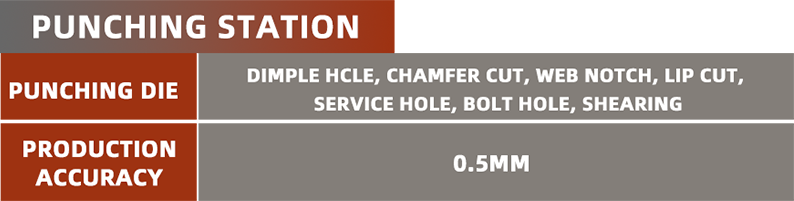

| Steel Framing Accuracy | 0.5mm |

Feature Of Light Gauge Framing Production Line

1. Read design data directly while in production, without manual intervention.

2. Real-time monitoring whole production process by graphics, which can show which work piece is working, the length, pcs and material condition etc.

3. Monitor and control the production process with automatic fault detection and alarm system to protection.

4. Improve efficiency to add, modify or cancel the task at any time, no matter single rob piece or whole unit. It can solve the scrap problem caused by material defect or personal error.

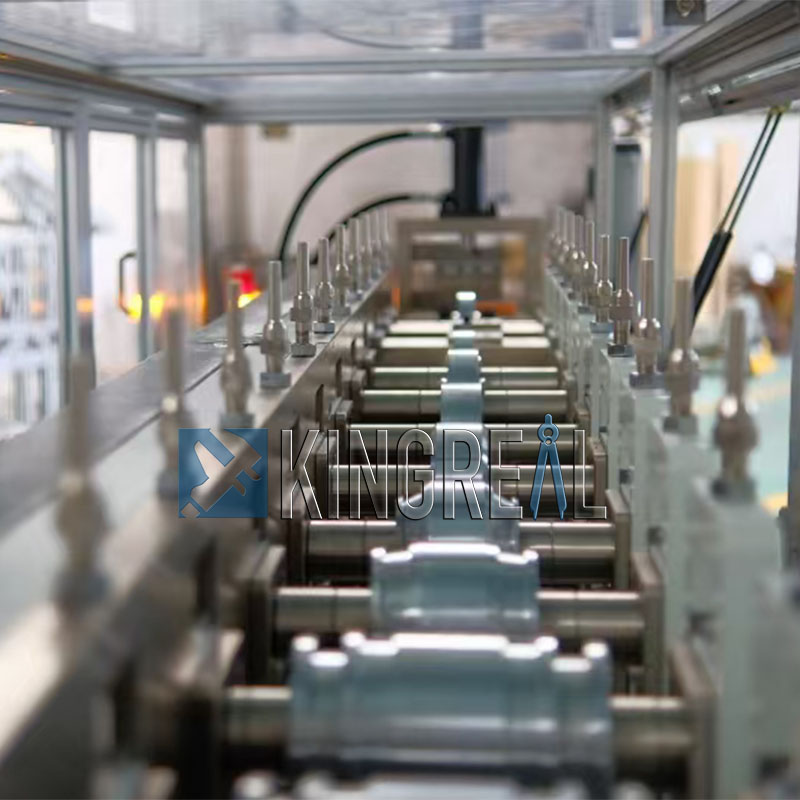

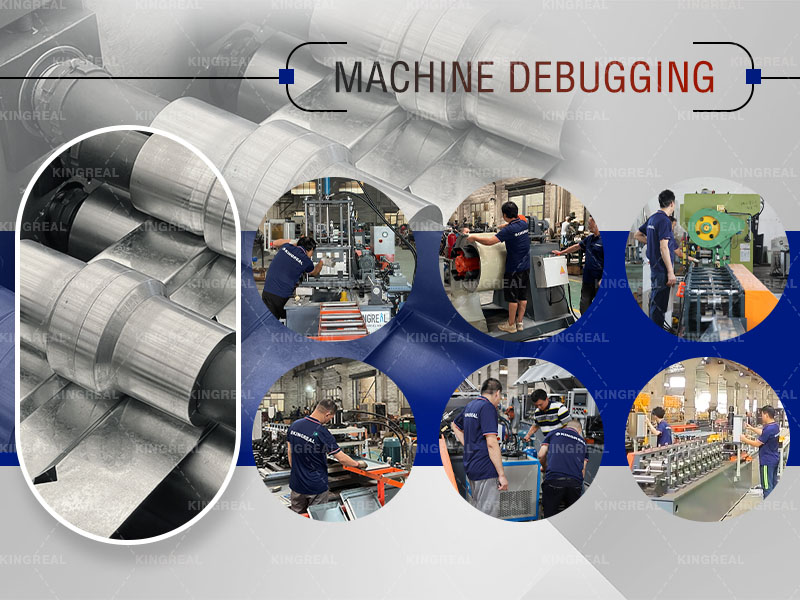

KINGREAL LGS Frame Machien In Factory

After the light gauge steel structure machine is manufactured, KINGREAL staff will conduct a series of detailed test runs. This process is not only a comprehensive test of the equipment performance, but also an important part of ensuring product quality and customer satisfaction.

After a series of detailed test runs, the performance of the KINGREAL lgs construction machine is satisfactory, mainly reflected in the following aspects:

√ The hydraulic parts are of excellent brand and reliable quality

√ High-precision punching to reduce waste generation

√ Fast drawing analysis to improve production efficiency

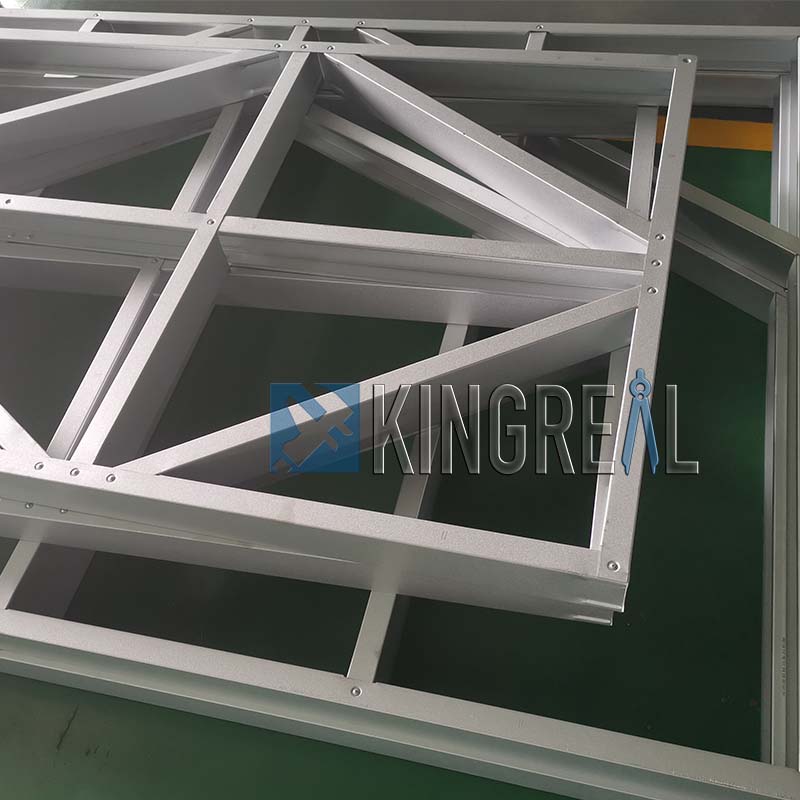

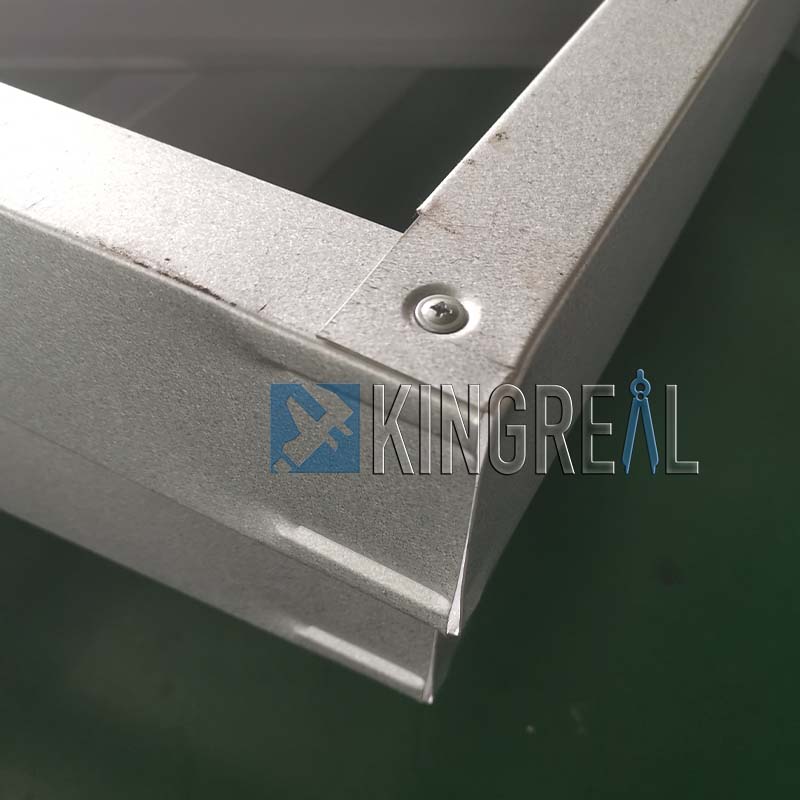

High-precision LGS Frame

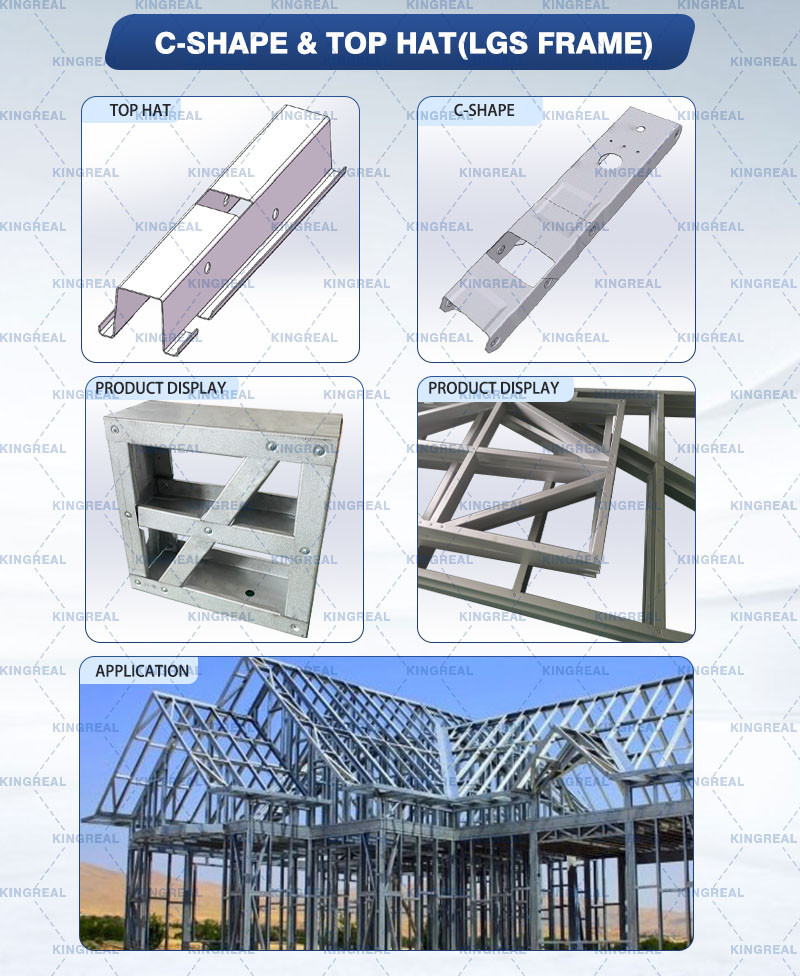

In order to better show the high-precision finished products produced by KINGREAL's light gauge steel structure machine, KINGREAL has compiled a series of real shots. Whether it is a C-frame or a Top Hat-frame, all finished products reflect KINGREAL's strict control of quality. Through these real shots, customers can intuitively feel the production capacity and finished product quality of KINGREAL light gauge steel structure machines.

Application Of Steel Frame Structures

LGS frame is an indispensable metal skeleton structure in modern buildings. It is usually made of galvanized sheet as raw material and rolled by cold bending process. LGS frame is widely used in building parts such as beams, walls, floors and roofs, providing strong and lightweight support for buildings. KINGREAL's light gauge steel structure machine can produce a variety of finished products, including C-type and Top Hat-type frames, to meet different construction needs.

Why Choose KINGREAL MACHINERY?

- Professional production capacity and technical team - Rich experience in production projects - Online after-sales service &b localized after-sales service - Arrange factory inspection service |  |

KINGREAL Exhibition

KINGREAL actively participates in domestic and foreign machine exhibitions to showcase its advanced technology and products. At the exhibition, the KINGREAL team attracted the attention of many customers with professional machine knowledge and enthusiastic service, and many customers reached a preliminary cooperation intention at the booth. KINGREAL looks forward to meeting more customers at future exhibitions to explore cooperation opportunities and jointly promote the development of the industry.