Linear Strip Ceiling Roll Forming Machine

KINGREAL MACHINERY is professional manufacturer the complete machine for metal linear strip ceiling, baffle ceiling roll forming line, open cell ceiling full automatic making machine,and other type metal ceiling making machine.We can making machine according with your different design and.

KINGREAL machines have exported to many oversea countries,and have the good reputations.We can provide the suitable solution of machine for you according to your detail request and product size.

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

Linear Strip Ceiling Roll Forming Machine

KINGREAL MACHINERY is professional manufacturer the complete machine for metal linear strip ceiling, baffle ceiling roll forming line, open cell ceiling full automatic making machine,and other type metal ceiling making machine.We can making machine according with your different design and. KINGREAL machines have exported to many oversea countries,and have the good reputations.We can provide the suitable solution of machine for you according to your detail request and product size.

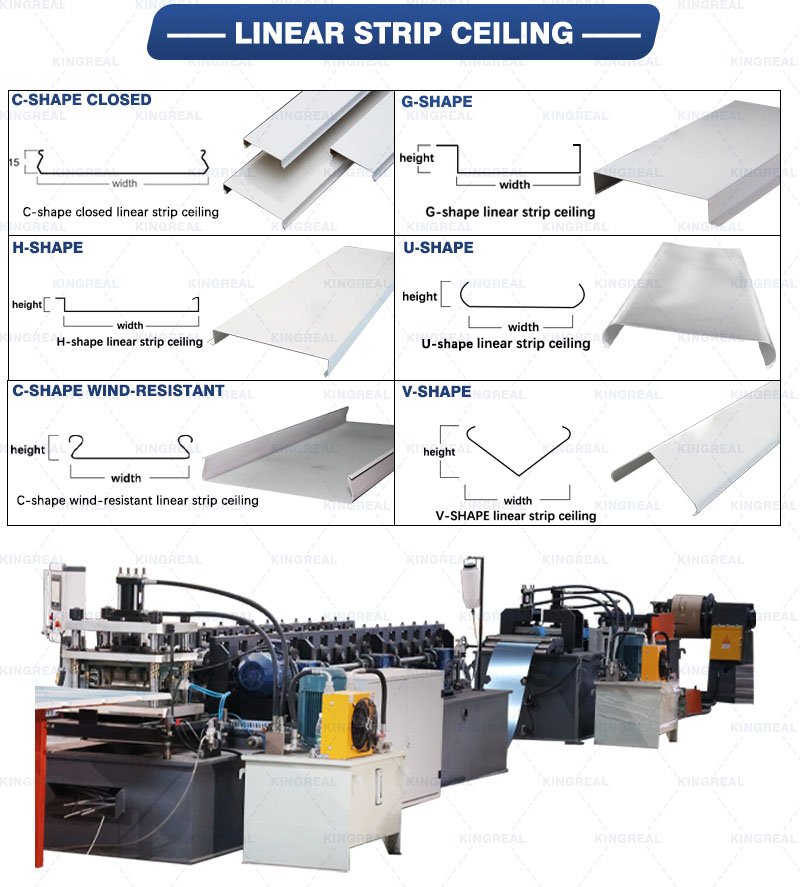

Linear strip ceiling system can absorb high levels of noise and it can be used both internally and externally. Sets of clips, hanging wires & metal ceiling linear strips are used for installation. Ceiling Strip with groove, ceiling strip without groove, self supporting with groove and selg supporting without groove linear strip systems give decrorative style and modernity with square edge strips.

Welcome to contact us if you have any requirements, we look forwards to cooperation with you !

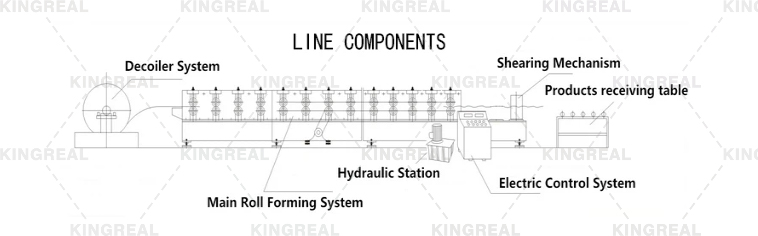

Components For The Linear Strip Ceiling Machine

| (1) Decoiler (2) Automatic cutting corner device (3) Roll forming machine (4) Leveling machine (5) Hydraulic bending device (6) Cutting mold & Bending mold (7) Product collecting table (8) Electrical control system |  |

Working Process Of Linear Strip Ceiling Equipment

Decoil roll material-----Cutting corner-----Leveling-----Feeding----Roll forming product-----Automatic bending-----Collecting product

Technical Specification Of Ceiling Strip Making Machine

S shaped strip ceiling roll forming machine Main parameters

| Line structure | Portal-type frame style, A3 steel |

| Forming Roller Stations | 12 Stations |

| Forming rollers | Cr12, Quenching, hardness HRC56-58º |

| Hydraulic punching system | Servo feeding; Holes position tolerance ±0.03mm |

| Forming Speed | 7-12 meters / min |

| Main motor | 5.5kw |

| Material of Sheet | Soft Quality (Annealed) Galvanized Sheet |

| Sheet Thickness | 0.3 to 0.5 mm |

| Cutting mode | Hydraulic automatic punching and cutting machine |

| Control Cabinet | 3xAC380v, 50HZ |

| Main machine sizes (L*W*H) mm | 6000*700 *700 |

Linear Strip Ceiling Machine Destail

| ①Hydraulic Decoiler Hydraulic uncoiler is a kind of mechanical equipment used for metal coil carrying discharge and unfolding. Effective prevention of loose material: Hydraulic unwinder adopts hydraulic expansion method instead of common hand-cranked expansion method, which ensures that heavy coils can still be tensioned inside the ring, thus effectively preventing the phenomenon of loose material. Flexible discharge speed control: the hydraulic unwinder is equipped with frequency converter to realize the function of speed regulation, which improves the stability of production and makes the discharge speed more flexible and controllable. |  |

②High Precision Straightener The 21-group roller precision leveler offers several advantages and is particularly suitable for high-quality leveling of precision materials. With 21 sets of rollers, the leveler provides higher leveling accuracy for applications that require extremely high plate flatness. Adaptable: capable of handling a wide range of plate thicknesses and materials, including stainless steel, brass, phosphor bronze, aluminum alloys and more. Highly efficient production: the design of multiple sets of rollers enables the leveler to complete the leveling of a large number of materials in a shorter period of time, improving production efficiency. |  |

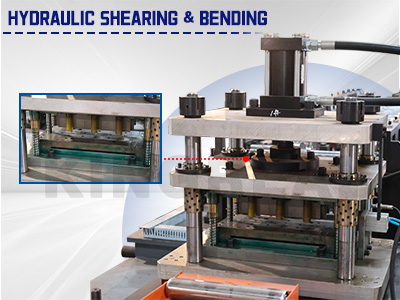

③Hydraulic Shearing a.The hydraulic parts use high efficiency environmental protection energy storage type hydraulic system. And it adopts Taiwan hydraulic components and equipped with air cooling system. b.Shearing Method: stop shearing, the blade material is Cr12Mov with quenching treatment hardness up to HRC60℃. |  |

Meeting respective usage and functions

(1) Metal false ceiling

(2) Metal strip ceiling

(3) Metal slat ceiling

(4) Metal buckle ceiling

(5) Metal linear ceiling

(6) Steel Purlin C Profile

(7) Metal pinch plate ceiling

(8) Aluminum C-shape long shape ceiling

(9) Galvanized steel furring channel ceiling

Quality Control

KINGREAL has established a strict quality control process to ensure that every production step meets the standards and requirements. This includes raw material procurement, production process, assembly, testing, etc. To ensure that every part of the machine meets quality standards. KINGREAL also passed the international CE certificate certification.

Installation Service

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

After-Sales Services

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what we have been insisting on doing. The global localization service point is under construction.