Metal Linear Strip Ceiling Making Machine

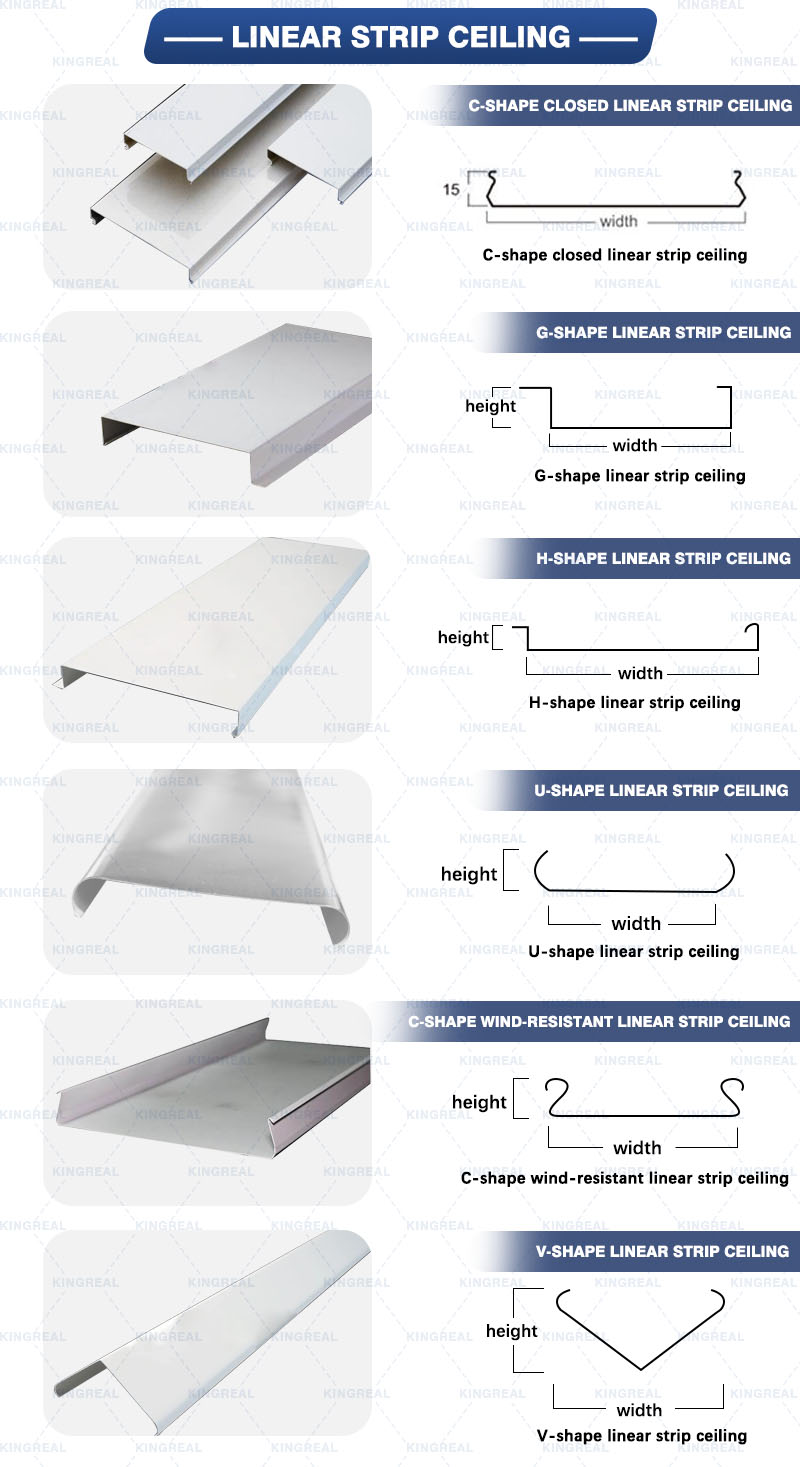

KINGREAL Metal Linear Strip Ceiling Making Machines can produce various sizes and shapes of linear strip products, such as R84, C-type, and S300 series etc. And we can according to your detailed requirements and product size to provide you with the appropriate machine solution.

- KINGREAL

- China

- 80 Days

- 9999

- Information

- Download

Machine Description

KINGREAL machinery offer full solution of high-quality Linear ceiling roll forming machines series, and they are widely used for cold roll forming of different kinds of linear strip ceilings, U shape baffle ceilings and other suspended metal ceilings. KINGREAL Metal linear ceiling making machine can produce different width of shape strip linear ceiling strips on the same system.

Only need simply input the requested with on touch screen, then the servo motor will drive the rollers to the requested position. Also, automatic edge bending is an option for the high-ends products clients.

KINGREAL linear ceiling making machinery Mainly include

1. U shape baffle ceiling roll forming machine (Auto width & height adjustable)

2. C-shape linear suspended ceiling roll forming machine

3. S-shape linear ceiling roll forming machine

4. H-shape linear suspended ceiling roll forming machine

5. G-shape linear ceiling roll forming machine

6. Round tube ceiling roll forming machine

7. V-shape strip ceiling roll forming machine

8. Aluminum Louver Ceiling roll forming machine

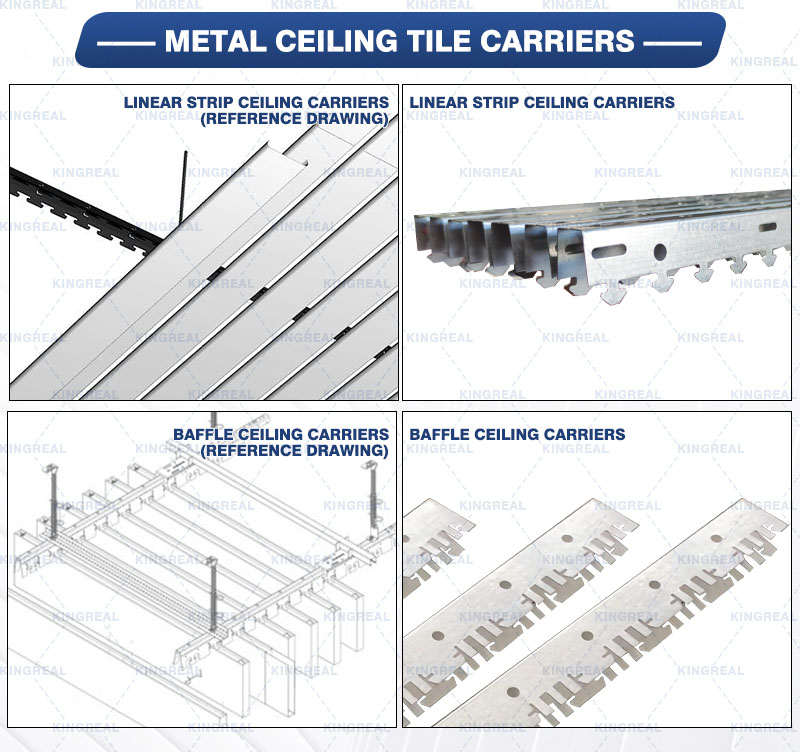

9. Linear Strip Ceiling Carrier roll forming machine

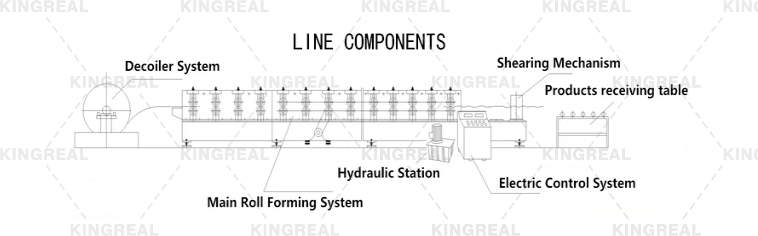

Structure of Metal linear ceiling making machine

- Hydraulic Decoiler - Main Roll Forming Machine - Shearing Station - Output Table - Electrical & Hydraulic System

Main Components Detail

1. Raw Material Uncoiler It adopts manual expanding frame and the capacity is 1.5 Ton. Manual feeding and manual expanding. a. Power: no. b. Decoiler speed: < 25m/min c. Max. Materials width: 400mm d. Max. Loading Capacity: 1.5ton e. Material Inner diameter: φ480mm-φ520mm f. Max material external Diameter: <φ1200mm |  |

| 2. Roll Forming Machine Detail a. Machine frame: the machine frame is fused together into a single piece structure using steel panels. Following fine processing by the planomiller, one panel with a thickness of 20 mm will be installed on the frame. This will guarantee the fundamental size accuracy. Additionally, it will strengthen the machine to lessen the impact of deformation. |  |

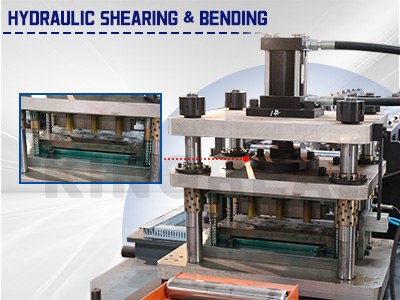

| 3. Hydraulic Bending Cutting Station High stability: the high rigidity frame design of the hydraulic bending machine ensures the stability of the machine in operation, and can withstand greater working pressure, and is not easy to produce vibration and deformation, so as to ensure the accuracy and quality of processing. High precision: Realize high-precision bending processing of various metal plates. By setting the corresponding parameters in the system, it is easy to realize various bending forms and realize the fine processing requirements. |

|

KINGREAL Ceiling Making Machine System

1. Baffle Ceiling Roll Forming Machine

2. Open Cell Ceiling Forming Machine

3. Metal Ceiling Carrier Forming Machine

Machine Quality Control

KINGREAL has established a strict quality control process to ensure that every production step meets the standards and requirements. This includes raw material procurement, production process, assembly, testing, etc. To ensure that every part of the machine meets quality standards. It has also passed the international CE certificate certification.

Installation Service

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.