Metal Cable Tray Roll Forming Machine

KINGREAL can supply Metal Cable Tray Roll Forming Machine, which design to produce different type cable tray produce according the customer needing!

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Cable Tray Roll Forming Machine Description

| Cable Tray Roll Forming Machine is a kind of industrial equipment specially designed for manufacturing cable trays, through which raw materials (usually steel or aluminum plates) are processed into various shapes and sizes of cable trays by automated process. In the electrical wiring of buildings, a cable tray system is used to support insulated electrical cables used for power distribution, control, and communication. Cable trays are used as an alternative to open wiring or electrical conduit systems and are commonly used for cable management in commercial and industrial construction. They are especially useful in situations where changes to a wiring system are anticipated, since new cables can be installed by laying them in the tray, instead of pulling them through a pipe. |  |

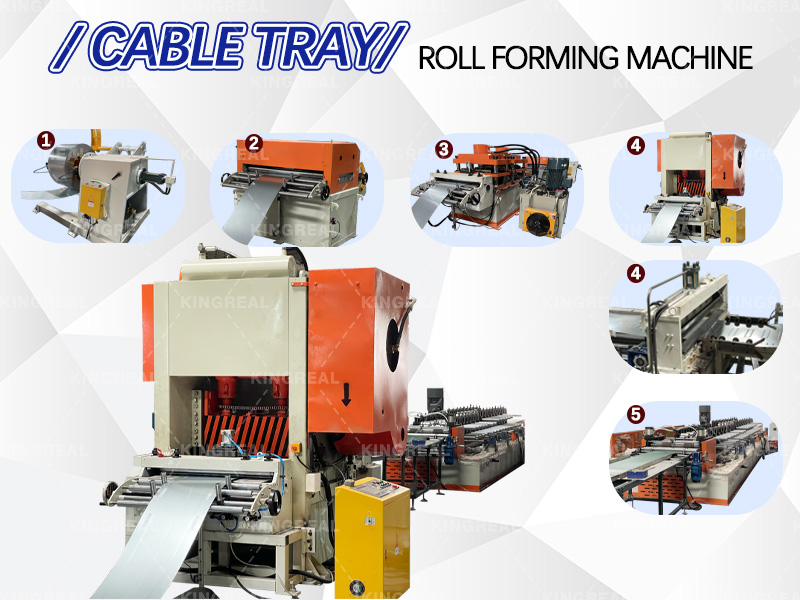

Main Components

Hydraulic Decoiler, Precision Straightening Machine, Hydraulic Notching Station, High-Speed Punching Press, Servo Feeders, Main Roll Forming Machine and Products Output Table.

Common Size About Cable Tray System

Gi Steel-made Cable Trays. Product width is adjustable from 200-600mm, can be set by computer control system, all machines will adjust as per requirement. Following pictures are 300mm width and 600mm width products

Features About Cable Tray Production Line

1. Yaskawa Servo Motors, Yangli 400tons High-Speed Punching Press, Worm Speed Reducers, High-Quality Hydraulic Stations, Computer Controlled Systems... We featured this production line with very powerful systems.

2. ±2.5mm Tolerance for Product Length, ±2mm Tolerance for Product Height, ±0.3mm Tolerance for Servo Feeding, Strict Quality Control System for Final Products, Samples Delivery for Clients’ Approvement, We do our best to make finished products the same as drawings.

3. CR12 Steel-Made Rollers, 40MM Thick Machine Panel, 80MM Diameter Main Axis, COPRA Software Designed and Verified by Experienced Engineers... The key components are made for the sole purpose – to let this production line serve our clients for a very, very long time.

Cable Tray Product Application

Product Display About Cable Tray System

Quality Insurance

KINGREAL has passed ISO9000 certification and has the ability of ISO9000 quality system management. It has also passed the international CE certificate certification.

Technology Support

As a professional manufacturer of roll forming machine in China, KINGREAL has been in design - production - installation - after-sales for more than 20 years. KINGREAL is able to customize production solutions according to customer‘s drawings and specific parameter requirements.

After you ordered, our technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.

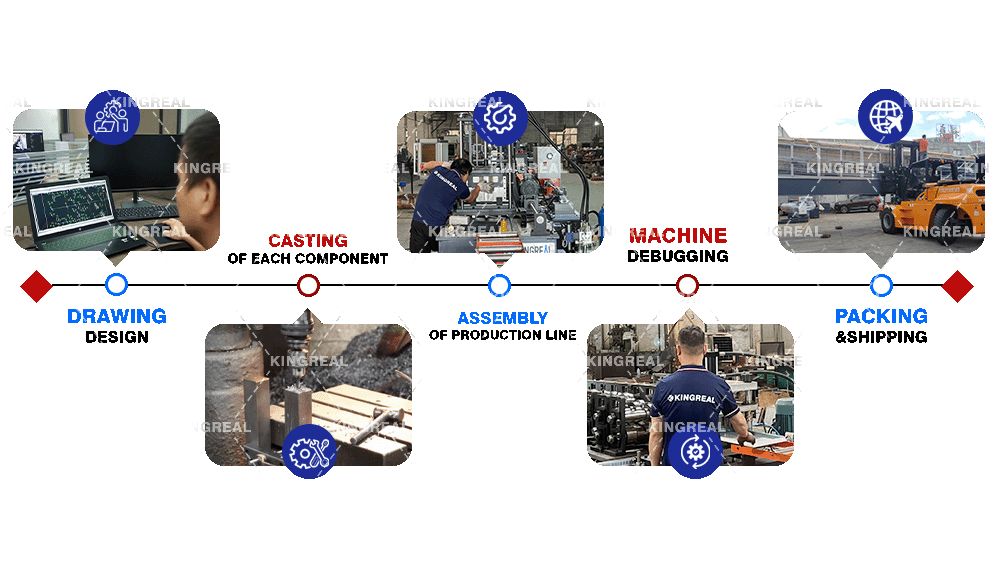

How To Process The Roll Forming Machine?