- Home

- >

News

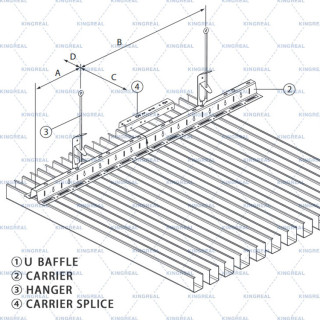

The baffle ceiling machine is used to produce U-shaped baffle ceilings at high speeds of up to 30m/min. The baffle ceiling production line mainly uses aluminum strip as raw material. After uncoiling, leveling, continuous rolling cold bending, and fixed-length cutting, it can produce U-shaped baffles of any size within the design range.

After research, KINGREAL engineers have launched a new design of a 300mm height baffle ceiling machine. Compared with the most common u baffle machines on the market, the rollers of KINGREAL 300mm height baffle ceiling machine use a hollow design, which can avoid the indentation of the finished product due to the weight of the rollers, ensuring that there is no indentation on the surface of the finished baffle ceiling. And the newly designed KINGREAL baffle ceiling machine can produce baffle ceilings up to 300mm.

KINGREAL MACHINERY has been designing, manufacturing and installing metal sheet processing equipment for more than 20 years, specializing in Metal Ceiling Equipment. In order to better develop the integration of industry and trade, and to control the quality of machine design and production more strictly, we have established our own factory in Foshan, Guangdong.