- Home

- >

News

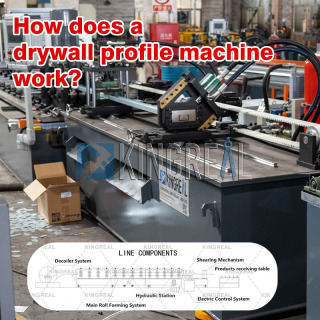

In modern construction engineering, production efficiency and precision are key factors for project success. Ceiling channel making machines, as highly efficient production equipment, are widely used in the construction industry. However, a single machine cannot independently meet complex construction needs. Only by using ceiling channel making machines in conjunction with metal stamping machines can a complete steel structure be formed, improving the production efficiency and installation quality of partition wall and suspended ceiling projects. This article will detail how ceiling channel making machines and metal stamping machines can be effectively combined to form a complete steel structure solution.

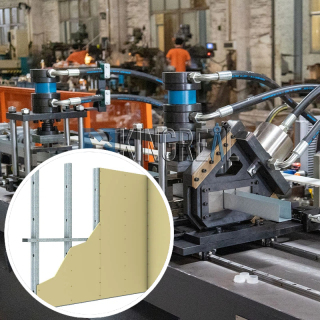

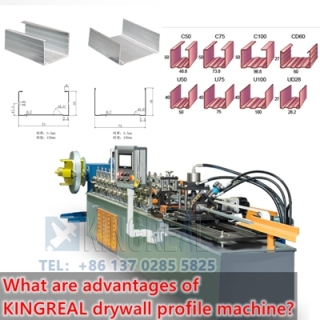

KINGREAL drywall profile machines are specifically designed for producing galvanized steel profiles for drywall applications. This highly efficient stud and track machine ensures precise manufacturing of studs and tracks, providing an ideal production solution for companies requiring large-scale production, high efficiency, and high-quality finished products. With the increasing demand for drywall materials in the construction industry, KINGREAL drywall profile machines are becoming the preferred choice for many companies.

This October, the Canton Fair was held as scheduled, attracting customers from all over the world to Guangzhou. KINGREAL factory, located just an hour's drive from the exhibition center, saw a significant increase in the number of customers it received. Customers from countries such as Israel, Singapore, Kuwait, and India visited the KINGREAL factory to learn about its various machines. In this article, KINGREAL will share some highlights from customer visits to the factory in October.

Metal stud and track machine, also known as drywall profile machine, gypsum board channel machine, and drywall stud and track machine, play a vital role in the modern construction industry. This drywall profile machine not only improves construction efficiency but also ensures the quality and precision of the finished product. Using galvanized coils as raw material, the metal stud and track machine utilizes a series of precision components, including the decoiler, main roll forming machine, hydraulic fly punching and shearing system, and product table, to produce metal studs and tracks of various specifications using a cold bending process. These studs and tracks are used as metal frameworks in construction projects.

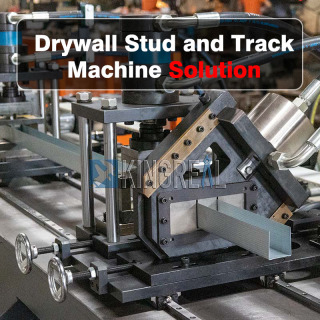

Drywall stud and track machine is also known as drywall profile machine, gypsum channel machine or gypsum board metal profile machine. It is a highly efficient equipment specially used for producing various specifications of stud and track. This drywall profile machine is designed to meet the needs of interior wall frames and non-load-bearing wall frames, and can complete the production of products of different specifications in a short time. This article will introduce the working process, finished product parameters, machine components and customized configuration of the drywall stud and track machine in detail to help customers better understand the advantages and applications of this drywall profile machine.

Drywall profile machines are one of the essential roll forming machines in the construction industry. These drywall stud and track machines are used to make frames for building walls, providing support and stability to the walls. In this article, KINGREAL will discuss various aspects of drywall profile machines with you, including its production process, advantages, potential applications, and more.

In the modern construction industry, the drywall profile machine is a key equipment that is gradually gaining favor among more and more builders and manufacturers. The drywall stud and track machine is designed for the production of galvanized steel non-load-bearing partition walls and has a wide range of applications, ranging from small residential to large commercial and industrial projects. KINGREAL can provide drywall profile machines with different configurations according to customer needs. If you are interested in KINGREAL drywall stud and track machines, please come and consult!

KINGREAL invites you to visit our factory on the occasion of the Canton Fair!

A drywall stud and track machine is a piece of equipment specifically designed to efficiently produce high-quality drywall studs and tracks. Its introduction has significantly improved production efficiency in the building materials industry.

Stud and track making machines are specifically designed for the production of gypsum ceiling profiles (studs and tracks). These profiles are essential components in suspended ceiling systems and are commonly used in residential, commercial and industrial buildings due to their light weight, thin thickness and fast assembly speed.

Last week, after the strict testing of the KINGREAL technical team, the KINGREAL stud and track machine with inkjet coding was confirmed to be able to run stably, and the maximum production speed can reach 100m/min, and it can produce wide and narrow studs and tracks of different sizes with high precision, etc., and then the ceiling channel machine was sent to the Greek customer's factory.

Stud and track machine is an important equipment in the field of building materials production. It is mainly used to produce drywall studs and tracks used in construction. These are widely used in the installation of suspended ceilings, partitions and frame structures. They have the advantages of light weight, high strength, fire resistance and corrosion resistance.