How To Manufacturing The Metal Roof?

2024-09-29 14:321. What is metal roof panel?

Metal roof panel refers to a roofing form that uses metal plates as roofing materials, combining the structural layer and the waterproof layer into one. There are many types of metal plates, including galvanized plates, aluminum-zinc plates, aluminum alloy plates, aluminum-magnesium alloy plates, titanium alloy plates, copper plates, stainless steel plates, etc. The surface of the plates can be painted.

2. The production process of metal roof panel

The production process of metal roof sheet is mainly divided into the following 4 steps:

(1) Uncoiling & Feeding

The decoiler machine uncoils the metal coil and feeds it directly into the metal roofing machine for the next step of metal roofing sheet production. You can choose a manual decoiler machine or an optional fully automatic hydraulic decoiler machine to increase the automation of the metal roof panel production line.

(2) Main forming part

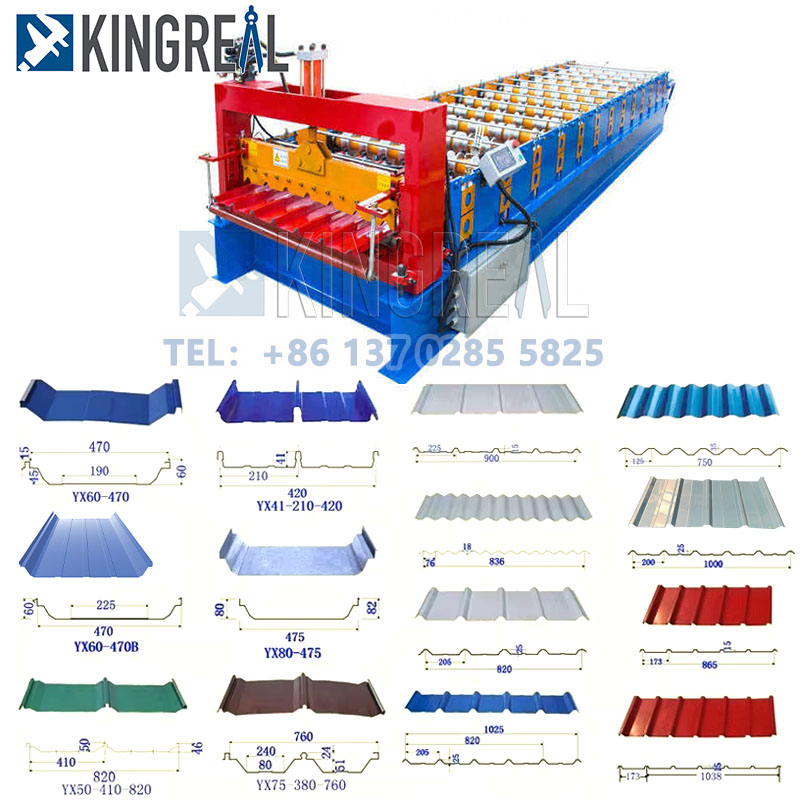

Depending on the production requirements of different metal roof panel manufacturers, the structure of the main forming machine will also be adjusted, such as single-layer metal roofing machine and double layer roofing sheet roll forming machine. After setting the parameters on the control panel, the main forming machine can automatically produce metal tiles of the required size. KINGREAL supports customized machine design and production. You only need to tell us your production requirements or provide sample drawings, and we can customize the appropriate metal roof sheet making machine design for you.

(3) Cutting

After the main forming machine forms the metal sheets, they are finished. The size of the metal sheet is set on the control panel, and the cutting station will automatically cut the formed metal tiles into the required length. The cut metal tiles are the final complete products, which can be directly sent to the construction site for installation or packaged and sent to the market for sale.

3. Characteristics of metal roof sheet

(1) Strong durability: The material of metal tiles determines its strong durability. It is not easily affected by natural forces such as weather and climate, and can remain the same for a long time.

(2) Good waterproof performance: The surface of the metal sheet adopts special treatment technology to make it waterproof and will not cause water seepage or leakage due to weather changes such as rainfall.

(3) Good windproof performance: The surface of the metal roof sheet is flat and fixed by riveting, making the entire roof very strong and able to resist the impact of wind well.

(4) Easy to install and maintain: Metal roof panel do not require much professional skills during installation. They are also relatively light and do not require the use of large lifting equipment. In addition, metal roof panels are relatively simple to maintain, requiring only regular cleaning and painting.

4. Application of roof panel

(1) Construction: Metal roof sheets are widely used in the construction field, such as commercial buildings, villas, industrial plants, etc. In addition to good decorative effects, they can also provide waterproof and windproof properties.

(2) Decoration field: Metal roof panels are widely used in house roofs, exterior wall decoration and other fields because of their beautiful appearance and diverse colors.