What are advantages of roof tile making machine?

2025-03-11 12:00Definition of roof tile making machine

Metal roofing machine is a kind of mechanical equipment specially used for producing various roof tiles. It is widely used in building structures such as roofs by processing metal coils or other materials into tiles of specific shapes. Roof tile machines can produce various types of tiles according to different design requirements to meet the diverse needs of the construction industry.

Application of metal roofing machine

The main purpose of roof tile machine is to manufacture roof tiles. Common types include corrugated panel, standing seam, glazed panel, IR panel, etc. These roof tiles can effectively improve the beauty and durability of buildings. In addition, roof tiles can also be used for insulation and heat preservation, improve the energy efficiency of buildings, and are suitable for residential, commercial buildings, industrial facilities and other fields.

Market demand for metal roofing machine

With the continuous development of the global construction industry, the demand for roof tile making machines has gradually increased in many countries and regions. The following are some countries with a large demand for metal roofing machines:

1. India

India's infrastructure construction is developing rapidly, and tiles are widely used as an important building material. The market potential of roof tile machines in India is huge, especially in rural areas, where the demand for roof tiles is particularly evident in traditional architectural styles.

2. Brazil

The construction industry in Brazil is booming, and the demand for metal roofing machines is also rising. Due to local climatic conditions, the waterproof and thermal insulation properties of roof tiles are valued, making roof tile machines one of the popular equipment.

3. South Africa

The demand for roof tiles in the construction market in South Africa continues to grow, especially in new residential and commercial buildings. The application potential of roof tile machines in this market is huge.

4. Europe

In many European countries, roof tiles still occupy an important position as a traditional building material. The market demand for roof tile machines in these countries is stable, especially in new construction and renovation projects.

Convenience brought by automated roof tile machines

With the advancement of science and technology, automation technology has been widely used in various industries, and the roof tile production industry is no exception. The introduction of automated metal roofing machines has completely changed the way traditional roof tiles are produced, bringing many conveniences to manufacturers and users.

1. Improve production efficiency

One of the biggest advantages of automated roof tile machines is that they greatly improve production efficiency. Traditional roof tile production usually relies on manual operation, and the production process is slow and prone to errors. Automated metal roofing machines can continue to produce through computer control and mechanized operation, significantly shortening the production cycle.

Automated roof tile making machines can achieve 24-hour uninterrupted production, reducing shift changes and downtime. This continuous production capacity enables manufacturers to meet the market's large demand for roof tiles, especially during the busy season of the construction industry, and can deliver orders in time to improve customer satisfaction.

2. Reduce labor costs

The introduction of automated metal roofing machines significantly reduces dependence on labor. Traditional production methods require a large number of workers to operate and monitor, and automated roof tile machine can largely replace these labor.

By using automated roof tile machines, companies can reduce the number of employees and reduce labor costs such as wages and training. This not only reduces the burden on enterprises, but also enables enterprises to focus resources on more valuable work, such as research and development and market development.

In addition, automated roof tile making machines reduce the direct participation of workers in production, thereby reducing the risk of work-related injuries. Many automated roof tile machines are designed with safety in mind and are equipped with a variety of safety protection measures to ensure that operators work safely under remote monitoring.

3. Improve product quality

Automated metal roofing machines can significantly improve the production quality of roof tiles through precise computer control and high-quality mechanical design.

In traditional manual operations, due to human factors, the roof tiles produced often have problems such as inconsistent size and uneven appearance. The automated metal roofing machine ensures that the size and shape of each roof tile meet the design standards through precise control, reducing the production of unqualified products.

In addition, modern automated roof tile machines are usually equipped with real-time quality monitoring systems that can detect each batch of products during the production process. This system can detect problems in a timely manner and make adjustments to ensure the quality stability of the final product.

4. Optimize resource utilization

Automated metal roofing machines also show significant advantages in resource utilization. Through efficient production processes and intelligent management, enterprises can make better use of raw materials and energy.

During the automated production process, the metal roofing machine can accurately calculate the amount of materials required and minimize the generation of waste. This efficient material utilization not only reduces production costs, but also plays a positive role in environmental protection.

Many modern automated roof tile machines focus on energy efficiency in design, and reduce energy consumption by optimizing mechanical structure and operation process. Energy-saving equipment not only reduces operating costs, but also contributes to the sustainable development of enterprises.

5. Enhanced safety

Automated roof tile machines not only improve production efficiency and reduce labor costs, but also enhance the safety of the production process.

Many automated metal roofing machines are equipped with remote monitoring systems, so that operators can monitor the production process at a safe distance and detect and deal with potential problems in a timely manner. This monitoring method not only improves safety, but also reduces workers' direct contact with dangerous environments.

Automated roof tile machines usually have fault detection and alarm systems. When the equipment is abnormal, the system will automatically stop working and sound an alarm to prevent accidents. This intelligent fault handling mechanism improves the safety and reliability of the production process.

Advantages of metal roofing machine

Metal roofing machines have many unique advantages in the construction industry, making them a popular equipment. Here are some of the main advantages of roof tile machines:

Can produce various types of roof tiles

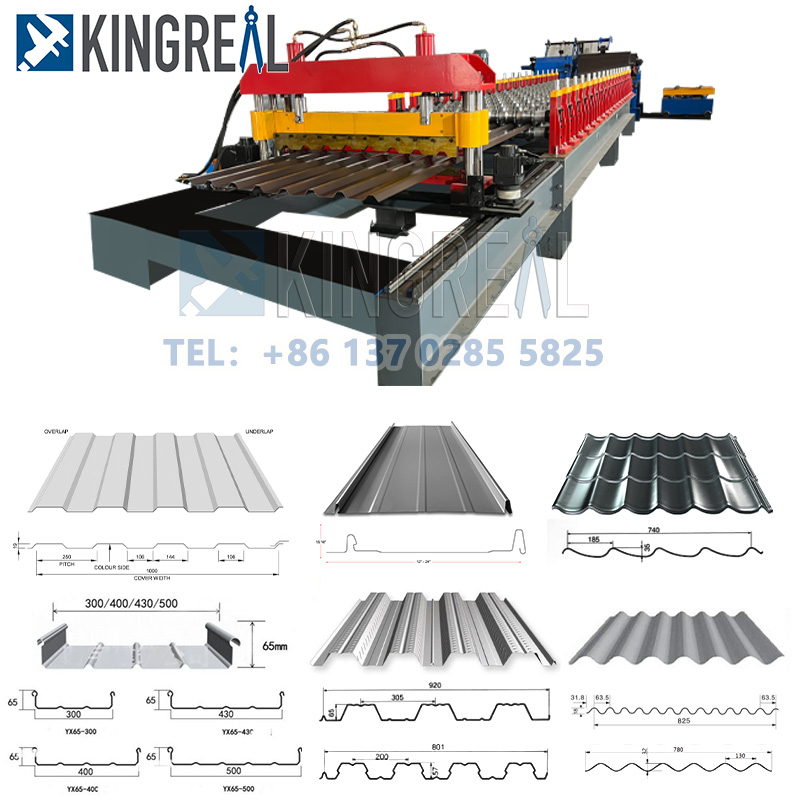

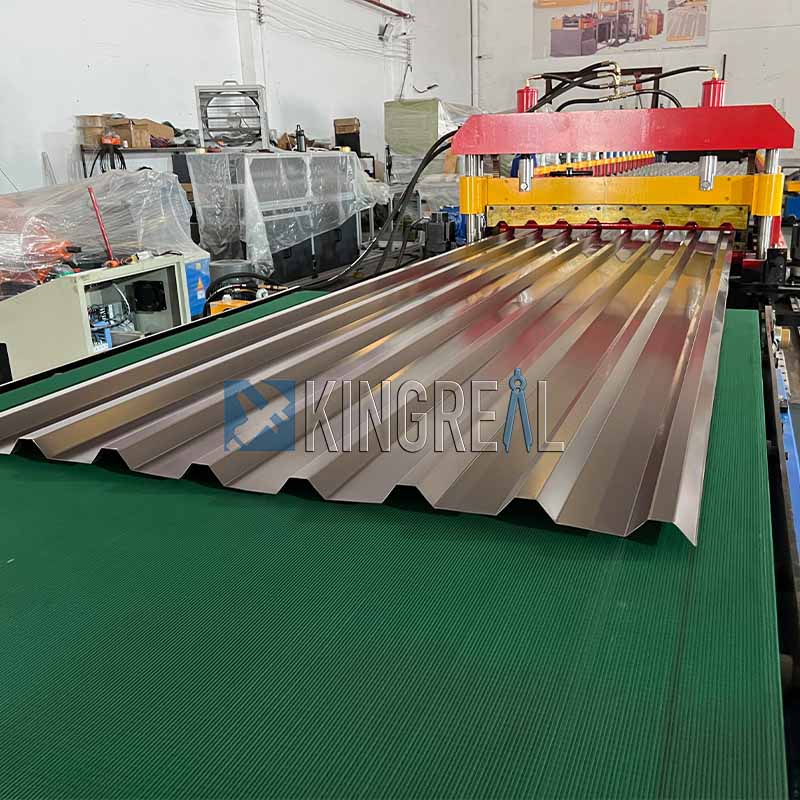

KINGREAL's metal roofing machines can produce many types of roof tiles. For example, roof tiles of various shapes and specifications such as corrugated panel, standing seam, glazed panel, IR panel, etc. can be completed through different settings. Different types of roof tile machines can meet the needs of manufacturers in different markets and provide more choices for customers.

Hydraulic cutting station with high precision

KINGREAL metal roofing machines are usually equipped with hydraulic cutting stations. This design significantly improves the cutting accuracy during the production process. The hydraulic cutting system can accurately cut according to the set size to ensure that the size of each roof tile is consistent. This high-precision cutting not only improves the quality of the product, but also reduces material waste and reduces production costs

High quality forming rollers

The forming process of the roof tile making machine depends on the design and quality of the rollers. KINGREAL roof tile machines are usually equipped with 18 to 20 rollers. This design can better control the forming process of the tiles and ensure that every detail meets the design requirements. At the same time, the rollers are made of high-hardness materials, which can withstand high-intensity workloads and extend the service life of the equipment. This durability makes the production process more stable and reduces the frequency of maintenance and replacement.

Double layer roof tile machine

The double layer metal roofing machine is an innovative design of KINGREAL in roof tile machines, which can produce IBR roof tiles and circular corrugated tiles at the same time. This versatile design not only improves production efficiency, but also provides manufacturers with greater flexibility to meet the changing needs of the market. This not only reduces production costs, but also improves the utilization rate of metal roofing machine