What is warehouse pallet rack machine?

2025-03-08 12:00Warehouse Pallet Rack Machine, also known as pallet upright rack machine, warehouse pallet rack making machine, is a device for the production of different sizes and types of columns. It produces pallet racks that meet the needs of the shelf system through multiple workflows such as unwinding, leveling, punching, forming and cutting. These pillars support the shelving system, carrying a variety of goods and ensuring storage efficiency and safety in places such as warehouses, supermarkets and offices.

Market demand for pallet upright rack machines

It is precisely because of the prosperity of the shelf system, the demand for warehouse pallet rack making machines is also very large. The pallet upright rack machine can efficiently and accurately produce various types of pallet racks to meet the needs of the market for different load-bearing capacities and designs.

In the modern logistics and warehousing industry, the market demand for pallet upright rack machines is growing day by day. This trend is mainly due to several factors:

1. The rise of e-commerce: With the popularity of online shopping, the demand for warehousing and logistics centers has increased sharply, promoting the construction of shelf systems.

2. Transformation of the retail industry: supermarkets and shopping malls have increased requirements for the diversity and flexibility of shelves, prompting an increase in demand for various shelf pillars.

3. Office storage needs: Modern office environments have increased demand for efficient storage solutions, requiring columns to adapt to different storage needs.

Upright racks in different shelving systems

Shelf systems can be divided into light, medium and heavy duty systems, each system has different requirements for the upright rack:

1. Load-bearing capacity

- Light shelving system: suitable for storing lighter items, the bearing capacity of the column is usually less than 300 kg.

- Medium shelving system: Designed for medium load, bearing range between 300 kg and 800 kg.

- Heavy shelving system: Strong load-bearing capacity, capable of supporting loads of more than 800 kg, suitable for storing heavy items, such as machinery and bulk materials.

2. Material and thickness

- Light shelving system: The column is generally made of thin cold-rolled steel or galvanized steel, and the thickness is smaller to reduce the overall weight.

- Medium shelving system: Column material thickness is moderate, usually using stronger steel to provide better strength and stability.

- Heavy shelving system: The columns are made of heavy steel and designed for high strength construction to ensure safety and stability under high loads.

3. Design the structure

- Light shelving system: the column design is simple, usually linear structure, easy to light and economic.

- Medium shelving system: Columns may have reinforcement or other structural designs to enhance load-bearing capacity and stability.

- Heavy shelving system: The column design is complex and often includes multi-layer reinforced structures capable of handling extreme pressures and shocks.

4. Accessory compatibility

- Light shelving system: accessories design is relatively simple, suitable for the storage of light goods.

- Medium shelving system: various accessories, can adapt to different types of goods storage needs.

- Heavy shelving system: Accessories designed specifically to support heavy loads often require stronger connections and support systems.

5. Application Scenarios

-Light shelving system: suitable for storage for small stores, offices or home use.

- Medium shelving system: widely used in warehouses, supermarkets and medium-sized enterprises.

- Heavy shelving system: mainly used in heavy industry, logistics centers and large warehouses.

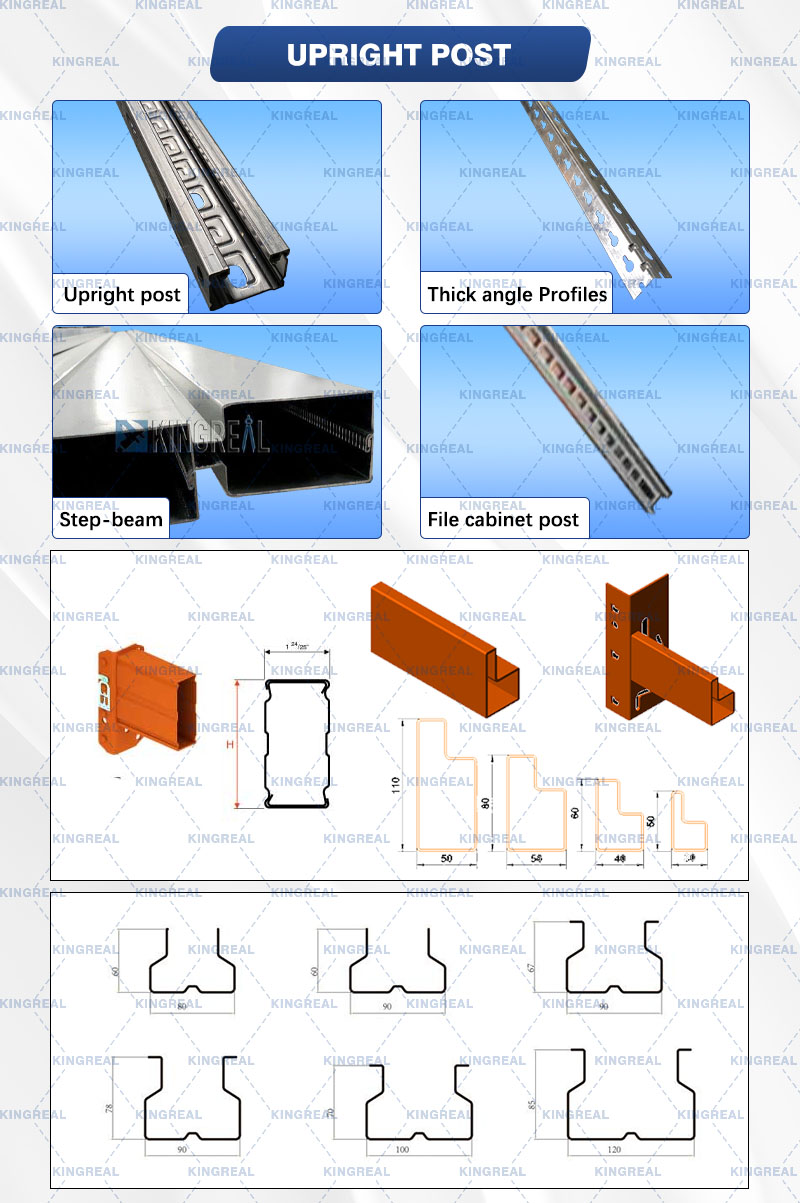

Common types of upright racks

In the shelf system, the type of pallet rack directly affects the bearing capacity, stability and application scenario of the shelf. Here are some common upright rack types:

1. Upright Post

Definition: Upright post is the most common type of upright post in a shelving system, usually mounted in an upright position as the main support structure for the shelf.

- Features:

- Material: Usually cold rolled steel or galvanized steel, with good load-bearing capacity and corrosion resistance.

- Design: Simple structure, usually linear, easy to produce and install.

- Load-bearing capacity: Suitable for light and medium-sized shelves, a wide range of load-bearing.

- Application: Widely used in warehouses, supermarkets and office environments, suitable for storing various types of goods.

2. Thick Angle Profile

Definition: A Thick angle is an angular column made of thick steel, commonly used in heavy-duty shelving systems.

- Features:

- Material: Thicker steel is used to enhance the strength and stability of the column.

- Design: The angular design makes it more stable under transverse and longitudinal pressures.

- Load-bearing capacity: suitable for heavy shelves, able to withstand larger weight of goods.

Applications: Mainly used in heavy industry, logistics centers and large warehouses, suitable for storing heavy equipment and materials.

3. Step-beam

- Definition: Step-beam is a specially designed beam, usually used in conjunction with a straight column to form a support structure for a shelf.

- Features:

- Material: Usually made of high-strength steel to ensure good load-bearing capacity.

- Design: The stepped design allows the shelf layers to be placed at different heights, facilitating the adjustment of layer spacing.

- Load-bearing capacity: suitable for medium and heavy shelves, strong load-bearing capacity.

- Application: Widely used in warehouses and logistics centers, especially for occasions where storage space needs to be adjusted frequently.

4. Box-Beam

Definition: A Box-beam is a beam of box-type construction commonly used in heavy-duty shelving systems to provide additional strength and stability.

- Features:

- Material: Commonly used high-strength steel, designed as a hollow structure, reducing weight while maintaining strength.

- Design: The box structure enables it to withstand greater loads and is suitable for high-density storage.

- Load-bearing capacity: Suitable for heavy duty shelves, especially in environments with high loads and high storage requirements.

- Application: Suitable for heavy industry, warehouses and logistics centers, especially where heavy goods need to be stored.

Main components of pallet upright rack machine

The warehouse pallet rack making machine consists of several key components, each of which plays an important role in the production process.

Punching machine

Punching machine according to customer needs on the metal coil punching, aperture and pass can be customized. KINGREAL's punching machines have the following advantages:

- Fast speed: efficient punching speed, can meet the needs of large-scale production.

- High precision: High punching precision to ensure that the size of each hole is consistent and meets the design requirements.

Roll forming machine

The roll forming machine is the most important part of the pallet upright rack machine. The metal sheet is cold-formed by the roll forming machine to form the column shape required by the customer. It features include:

- High quality roller: high hardness, wear-resistant roller to ensure stability and consistency in the forming process.

Cutting station

The cutting station is responsible for cutting the formed columns according to the length set by the customer. KINGREAL's cutting stations offer the following advantages:

- High quality blade: equipped with high hardness blade, smooth incision during cutting, reduce subsequent processing processes.

- Intelligent control: Through intelligent device control, the cutting length is fully in line with customer set parameters, improving production efficiency.

Selection of warehouse pallet rack making machine considerations

When choosing a warehouse pallet rack making machine, one of the most important considerations is the quality of the machine. High quality pallet upright rack machines not only ensure the smooth operation of the production process, but also significantly improve production efficiency. Stable operating status means that equipment can maintain consistent performance over long periods of time, thus reducing downtime due to equipment failure. This is of great significance for enterprises that pursue efficient production.

High quality warehouse pallet rack making machines usually have a longer service life because they are designed and manufactured with durable materials and advanced technology. This durability not only reduces the chance of damage to the pallet upright rack machine, but also reduces the cost of servicing and replacing parts. For enterprises, lower maintenance costs mean a higher return on investment, which can effectively optimize the operating budget.

KINGREAL is always committed to providing the highest quality warehouse pallet rack making machines. KINGREAL selects the highest quality raw materials in the manufacturing process to ensure that every pallet upright rack machine has excellent performance and durability. In addition, after the production of the pallet upright rack machine is completed, KINGREAL carries out a series of rigorous quality inspection procedures. These tests not only cover the overall performance of the warehouse pallet rack making machine, but also include a detailed examination of each roller and component. KINGREAL carefully measures the dimensions of each component to ensure that they fully conform to the parameters specified on the design drawings. This meticulous quality control process is designed to ensure that each pallet upright rack machine is able to demonstrate its superior performance and reliability in practical applications.