What is the difference between hr and cr aluminum coil?

2024-11-20 18:24"The production process is the core competitiveness of aluminum coil manufacturers. With the progress of science and technology, modern aluminum coil production has achieved a high degree of automation and intelligence. From melting, casting, hot rolling, cold rolling to cutting and packaging, each link is equipped with advanced equipment and technology. For example, the use of advanced melting technology can effectively control the content of gas and inclusions in the aluminum liquid, and improve the purity and mechanical properties of aluminum coils; while high-precision cold rolling units can ensure the surface finish and flatness of aluminum coils to meet the stringent requirements of high-end markets."

The Application Range Of HR And CR Aluminum Coils?

Due to the good mechanical properties and ductility of hot rolled aluminum coils, it is more suitable to be used in occasions where it is required to withstand large stresses and deformations, such as automobile bodies, building curtain walls, and so on. In the aerospace field, hot rolled aluminum coils are also widely used due to their excellent performance. In addition, hot rolled aluminum coils have good corrosion resistance and processability, and can meet the needs of a variety of complex processes.

Cold rolled aluminum coil because of its good surface quality, high dimensional accuracy and excellent bending and tensile properties, in the mold manufacturing, precision instruments and instrumentation manufacturing and other fields occupy an important position. With the continuous development of industrial technology, the demand for high-precision, high-performance materials is increasing, and the market demand for cold-rolled aluminum coils is also expanding.

Production process of hot rolled and cold rolled aluminum coils

The production process of hot rolled aluminum coils is relatively complex and continuous, mainly including raw material batching, ingot melting, continuous casting, heating and rolling, cooling and quenching, straightening and trimming, passivation treatment and other links. Among them, heating rolling is the core step, through the plastic deformation at high temperature, the aluminum ingot gradually thinning and achieve the required size and performance. Cooling and quenching help to fix the organization of the coil and improve its mechanical properties.

The production of cold rolled aluminum coils is relatively simple, relying mainly on the strong pressure of the cold rolling mill to further process the hot rolled aluminum coils at room temperature or low temperature. During the cold rolling process, the aluminum coil is rolled through multiple passes, gradually thinning to the target thickness, while obtaining a more uniform surface and higher dimensional accuracy. Since no heating is involved in the cold rolling process, energy consumption is low, which is conducive to energy saving and emission reduction.

Processing of hot and cold rolled aluminum coils

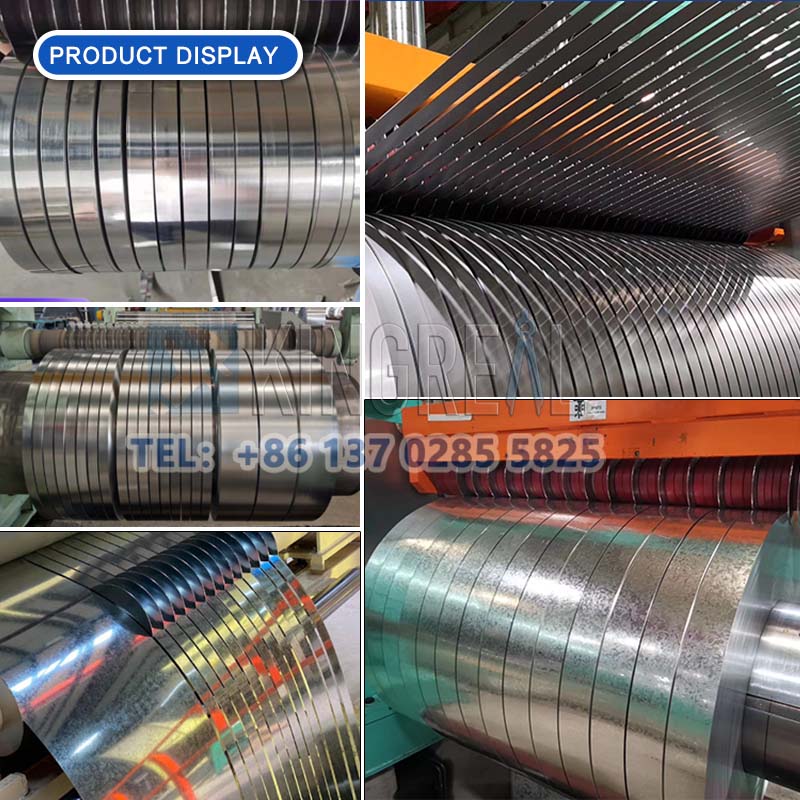

Coil Slitting Machine is the process of cutting a wide aluminum coil into several narrow coils, which is commonly used in the processing of aluminum coils after hot and cold rolling. The slitting machine first unrolls the aluminum coil and cuts it into narrow coils of the required width by adjusting the spacing of the cutters. This process allows for the flexible production of aluminum strips of various specifications for the manufacture of electronic products, automotive parts, etc., according to the needs of different applications.

Cut-to-length shearing line is the process of cutting aluminum coils into flat sheets of fixed dimensions, usually used for processing aluminum coils after cold rolling. The cut-to-length shear cuts the aluminum coil into sheets of the desired length through a series of precise shearing operations. This process is particularly suited to the production of aluminum sheets required by industries such as construction, marine and home appliances, ensuring that each sheet is the same size for subsequent processing and installation.