Baffle Ceiling Carrier Roll Forming Machine

KINGREAL Baffle Ceiling Carrier Roll Forming Machine is specially designed for the production of baffle ceiling carrier products, which are typically used in conjunction with baffle ceiling installations. Typically consists of 2 In 1 feeding equipment, high speed punch presses and molding machine equipment.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video Display

Description Of Baffle Ceiling Carrier Roll Forming Machine

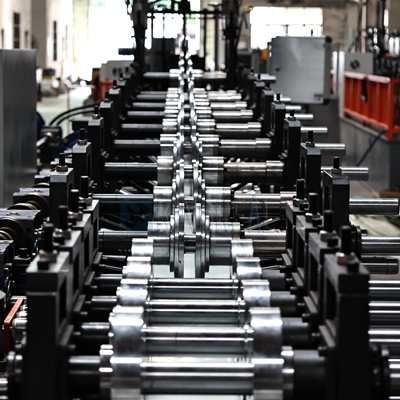

KINGREAL Baffle Ceiling Carrier System Roll Forming Machine is for production the carrier for the baffle ceiling, the whole production including combine decoiler & straightener, auto punching machine, roll forming line part, shearing part and electrical control system. The whole baffle ceiling carrier machine adopts the steel structure, the whole processing after welding, the bearing capacity is strong, and the operation is stable and reliable. The important parts of the baffle ceiling carrier machine and the components are all equipped with accessories from well-known domestic enterprises, thus effectively ensuring the performance of the equipment. KINGREAL u baffle ceiling carrier equipment is featured with high precision, high speed perforation and roll forming. The main machine including combined straightener and decoiler, high speed perforation press, high precision servo feeder system, high precision roll forming machine and follow shearing system. |  |

Technical Specification

| Raw material | Gi steel |

| Product shape | As per clients requests |

| Product length | 3000mm |

| Production capacity | 30m/min |

| Electricity requirement | 380V 50Hz 3 Phases |

| Power consumption | 10KW |

Main Component Details

Punch Press 25ton High Performance International Standard & NC Servo Feeder KINGREAL use 25 tons high speed press to punch the hole. And the machine including one set of punch mold. The press is famous brand YANGLI, China. This punch press needs compressed air connection. |  |

Structure of a Strong Roll Forming Machine The single-piece machine frame for the KINGREAL is made by welding together steel panels. One panel, 30mm thick, will be fitted to the frame after meticulous processing by the Plano miller. This will ensure the precision of the fundamental size. The machine will also be strengthened in order to resist deformation and ensure long-term performance. |  |

Unparalleled Independent Archway Panel Construction KINGREAL offer a superior independent archway panel construction for roller groups. Archways were processed and surface treated after being cast utilizing our original design. KINGREAL arches are not only strong and durable, but also provide stable properties. |  |

Two Solution Of Metal Ceiling Carrier Roll Forming Machine

1. Linear Strip Ceiling Carrier Roll Forming Machine

Linear Strip Ceiling is a common interior decoration material consisting of multiple parallel aluminium or steel strips joined together to form a grille-like structure and installed on the interior ceiling. Strip ceilings are commonly used in commercial buildings, public spaces, offices and other interiors.

The installation of a linear strip ceiling requires a combination of carrier profile. KINGREAL has designed and supplied linear strip ceiling roll forming machine for this purpose.

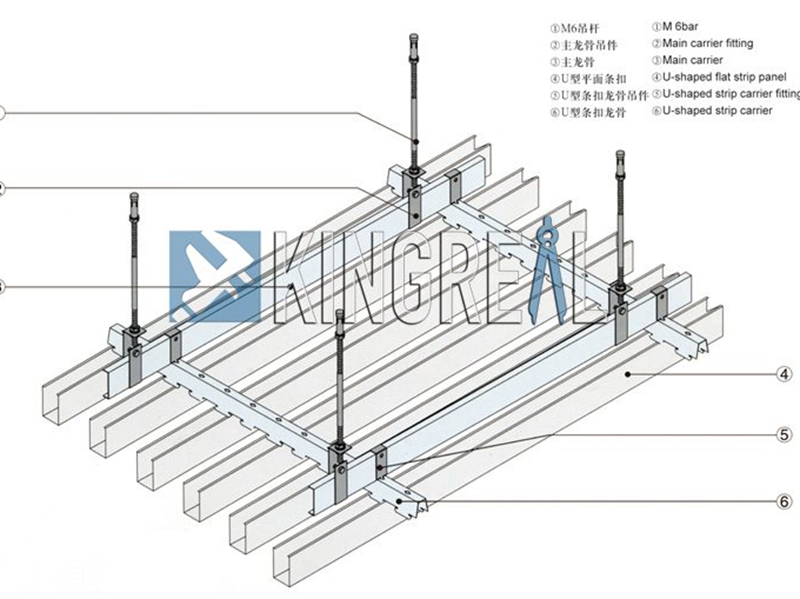

2. U Baffle Ceiling Carrier Roll Forming Machine

The U Baffle Ceiling is a more decorative ceiling, consisting of many squares of aluminium alloy or steel, which can be formed into different patterns and shapes. With the advantages of being lightweight, fireproof, moisture-proof, easy to install and maintain, the baffle ceiling is widely used in the interior decoration of commercial, office and hotel premises.

KINGREAL U Baffle Ceiling Roll Forming Machine can produce 150mm, 200mm and 300mm different sizes u baffle ceiling product. And can also provide the Baffle Ceiling Carrier Production Line to produce the carrier profile, which used to installed the suspended baffle ceiling.

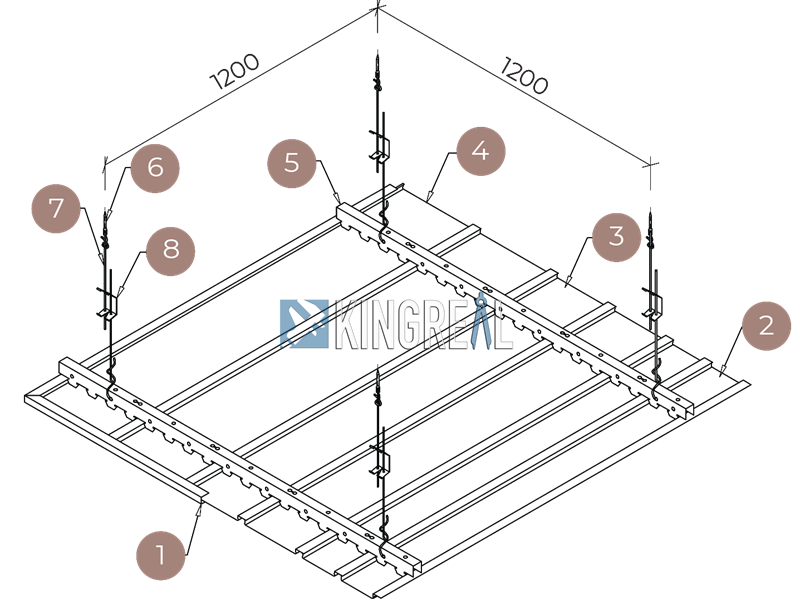

Metal Ceiling Carrier Installation

Linear Strip Ceiling System

Baffle Ceiling System

Both the baffle ceiling carrier and the linear strip ceiling carrier have the advantage of being easy to install. After installation, the hardware accessories can be hidden, which improves the visual beautification effect and the convenience of maintenance. If there is local damage, it can be replaced separately. It plays a supporting role in the metal ceiling system and is an indispensable part.

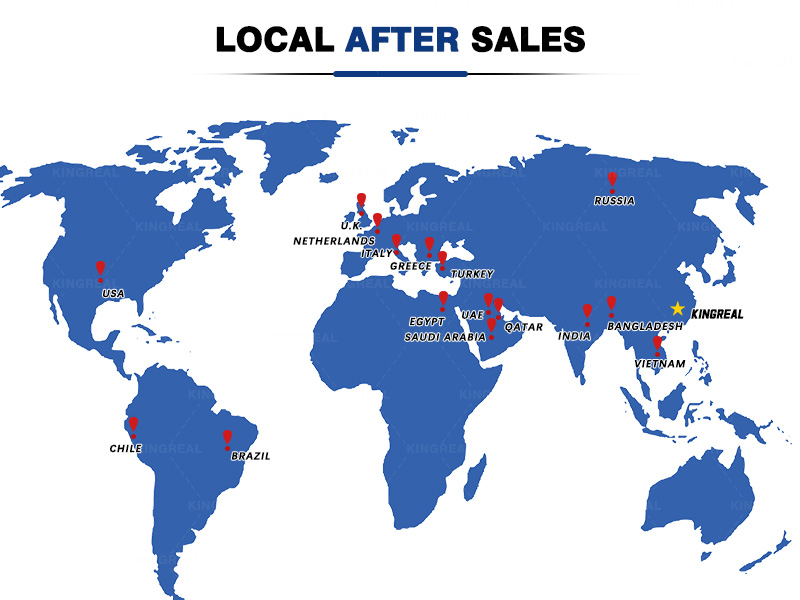

After Sale Service

Services are always highly considered by us, in addition to establishing a complete remote service system, localized after-sales service is also what KINGREAL have been insisting on doing. The global localization service point is under construction.