Linear Strip Ceiling Carrier Roll Forming Machine

KINGREAL can provide Metal Ceiling Carriers Production Line, which can produce carriers profile for multiple metal ceiling products, including linear strip ceiling, metal baffle ceiling and metal ceiling tiles etc. Linear Strip Ceiling Carrier Roll Forming Machine possibility producing different sizes and shapes of carrier according to customer requirements.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video Display

Description Of Linear Strip Ceiling Carrier Roll Forming Machine

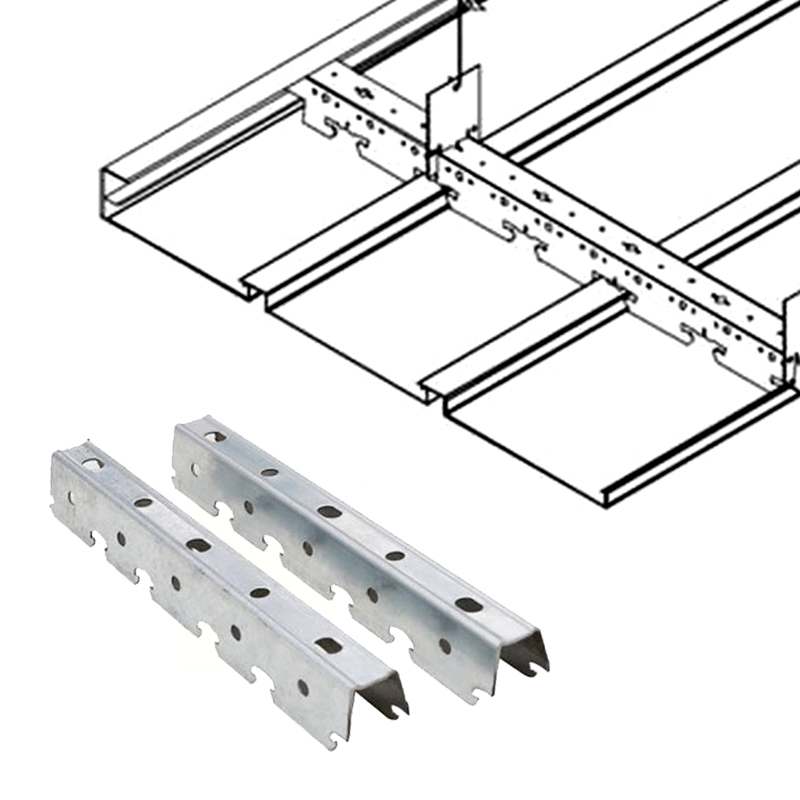

KINGREAL Metal Ceiling Carriers Production Line can produce carriers for multiple metal ceiling products, including linear strip ceiling, metal baffle ceiling, metal ceiling tiles etc.The Linear Strip Ceiling Carriers Roll Forming Machines are adapted to the specifications and sizes required for the production of different types of ceiling stud products.

Different metal ceiling carriers for different metal ceiling systems. KINGREAL can customize the production line to let it meet clients needs. This linear strip ceiling carrier production line is featured with precision punching press, quality roller stations, follow shearing station for fast cutting and touch screen display for easy operation.

Main Components Of The Line

- Combine decoiler&straightener - Punching press&servo feeder- Main roll forming machine - Automatic shearing station - Product output table and Electrical control system. |  |

Technical Specification

| Machine Name | Metal Ceiling Carriers Production Line |

| Products Name | Metal Carriers With Different Sizes |

| Products sizes | As per requirements from clients |

| Automation | Manual Operation/Full-Automatic Production with PLC |

| Certificate | CE certificate, ISO 9001 certificate |

| Machine Power | 380V 50HZ or according with customers request |

| Speed | 0~20m/min, Hydraulic Follow Shearing System |

| Main Features | Equipped with air cooling system, Famous brand hydraulic system, light curtain safety protection |

Main Components Details

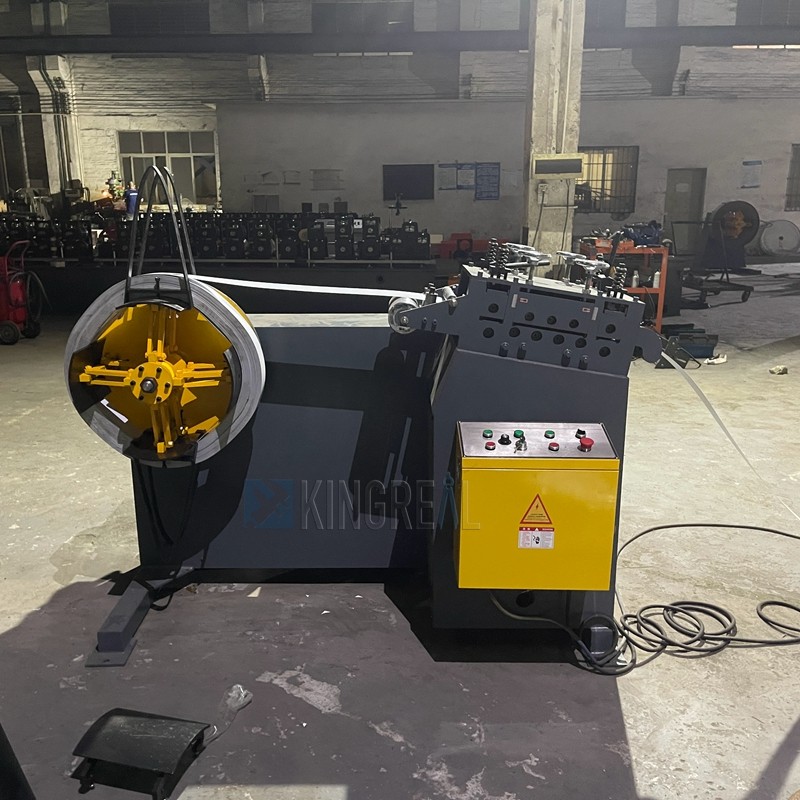

Combine Decoiler & Straightener2 In 1 The KINGREAL 2 in 1 decoiler & straightener is used for coil sheet metal unwinding and straightening tasks. Decoiler and straightener are both present in this combo. KINGREAL offers a hydraulic decoiler, a manual decoiler, and an optional trolley for fully automatic metal loading in order to adapt to changing demands. High precision straightening is offered by the straightener. KINGREAL ensures that the materials are straight and that the completed goods are highly accurate by doubling the number of rollers. |  |

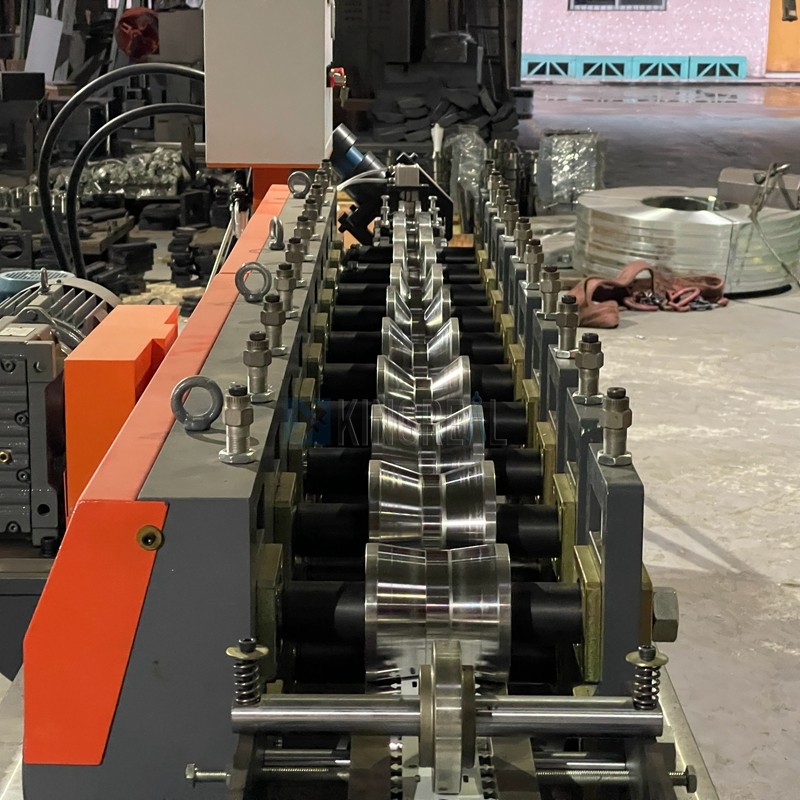

Strong Roll Forming Machine Structure Steel panels are welded together to form the single-piece KINGREAL machine frame. Following careful processing by the Plano miller, one panel with a 30mm thickness will be mounted to the frame. This will guarantee the fundamental size accuracy. Additionally, it will strengthen the machine to prevent deformation and assure long-term performance. |  |

Exceptional Independent Archway Panel Construction For roller groups, KINGREAL has a superior independent archway panel structure. Archways were cast using our unique design, processed, and surface treated. Our arches offer stable features in addition to being sturdy and long-lasting. |  |

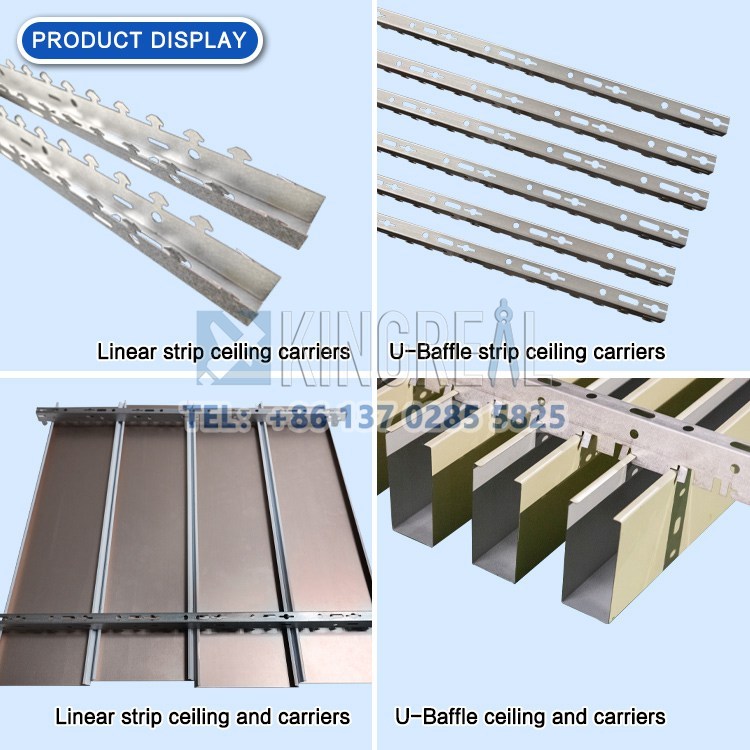

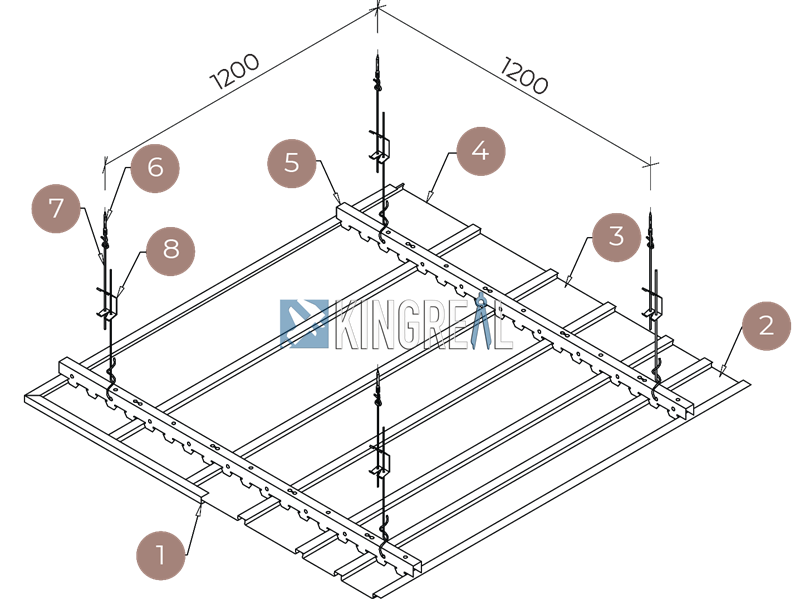

Linear Strip Ceiling Carrier Product

Complete Linear Strip Ceiling System

When installing a linear strip ceiling, the linear strip ceiling carrier is an indispensable basic part. After the ceiling carrier is correctly installed, the linear strip ceiling is fixed on it to achieve the ideal decorative effect. The linear strip ceiling and the strip ceiling carrier together constitute the core of the ceiling system, and the coordination of the two directly affects the overall effect and performance.

KINGREAL not only provides customers with linear strip ceiling carrier roll forming machines, but also linear strip ceiling machines to ensure that the two products can be perfectly matched. KINGREAL is committed to providing customers with a complete linear strip ceiling system, ensuring that each component can be seamlessly connected, bringing high-quality performance and beautiful effects to customers' projects.

Quality Control

KINGREAL has passed ISO9000 certification and has the ability of ISO9000 quality system management.

After you ordered, our technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.

KINGREAL After Sale Service

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.