Triangle Tee Roll Forming Machine

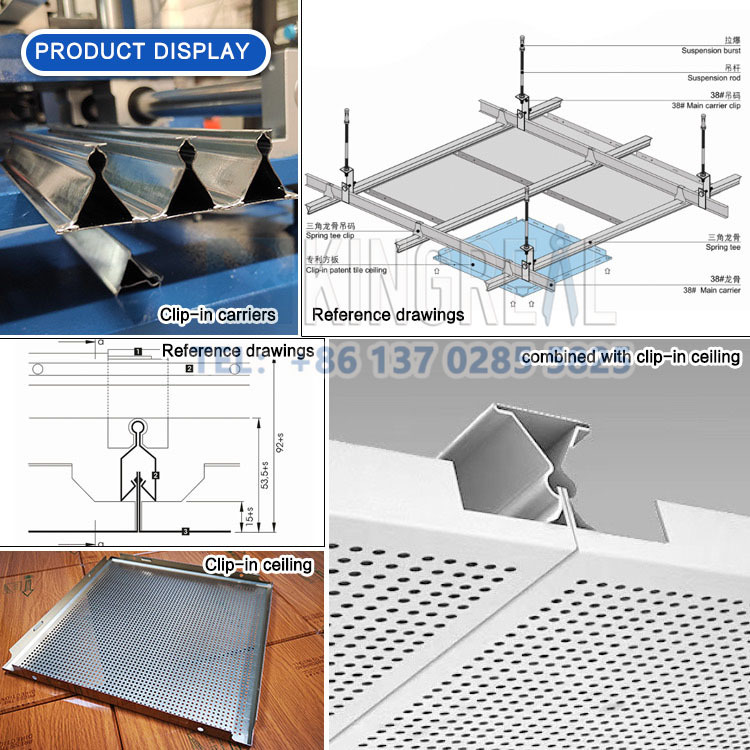

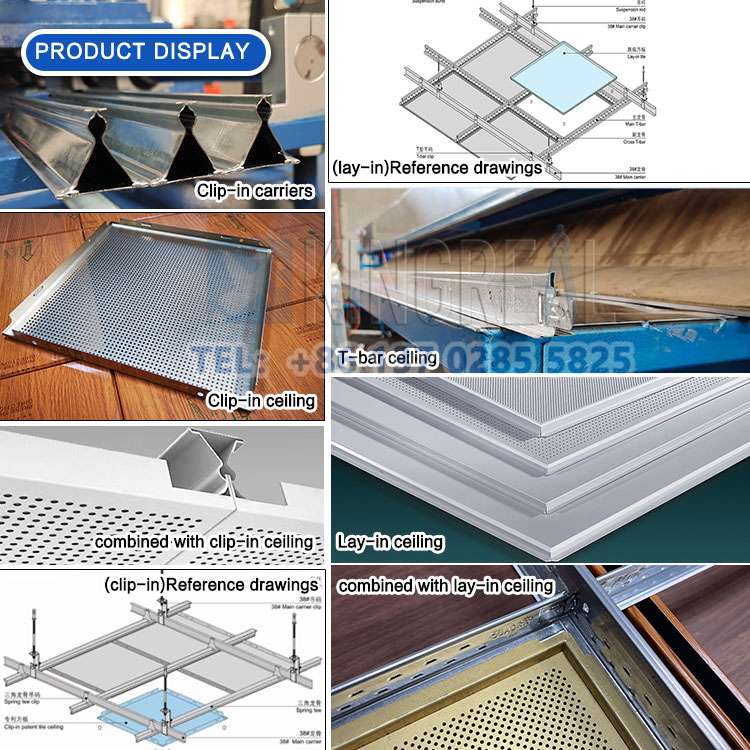

KINGREAL can provide the triangle tee roll forming machine ( also called spring tee roll forming machine), which is design for carrier the suspended clip-in metal ceiling tile and other construction of frames and support structures for large buildings.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video Display

Description Of Triangle Tee Roll Forming Machine

KINGREAL Triangle Tee Roll Forming Machine is one of the most popular type of carriers for Clip-in Metal Ceiling Tiles. This spring tee production line is featured with precision roll forming and high-speed follow shearing. The Spring Tee Making Machine is compatible with stainless steel or galvanized steel as raw material. It can produce carriers for different sizes of metal ceiling tiles such as 300x300mm, 300x600mm, 450x450mm, 600x600mm etc. With metal ceiling tiles production line, these 2 machines can manufacture a complete metal ceiling tiles system.

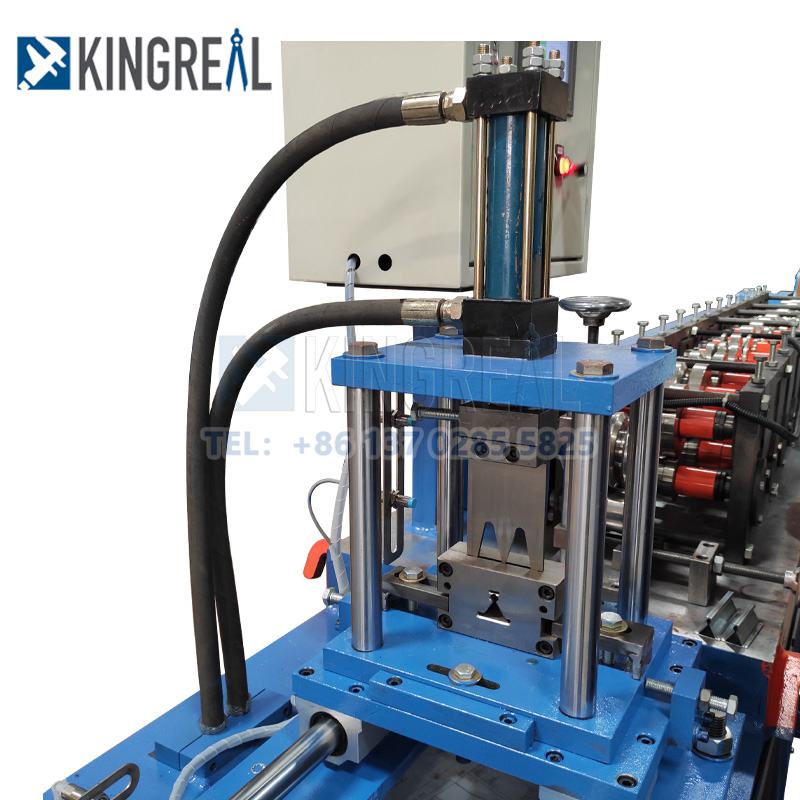

KINGREAL use quality servo motor from famous brand YASKAWA to build our hydraulic follow shearing station, which provides an unbelivable of 100m/min production speed maximum. All specifications can be easily set in the touch screen operating system with multilingual support. Instructions from operator will be transformed by quality PLC control system to let rollers act accordingly.

Main Components Of Triangle Tee Production Line

- Decoiler - Main roll forming machine |  |

Feature Of Spring Tee Roll Forming Machine

High Precision Cr12MoV forming rollers Cr12mov mold steel, heat treatment hardness up to HRC 580-600. Which is processed by CNC machine. |  |

High Speed follow Shearing System KINGREAL use high speed follow shearing system to guarantee non-stop working of the whole production line. Usually powered by high-precision servo feeder, linked with planetary reducer, our high speed follow shearing system drives cutter via synchronous belt to cut. The hydraulic part of cutter is pressurised to ensure quick action and reset. The KINGREAL high speed follow shearing system has the characteristics of high speed, high precision and automation. It is the BEST choice of high-speed automation solutions. |  |

High Quality Electrical Appliances KINGREAL use high-quality imported electrical appliances, such as Japanese Yaskawa NC servo feeder, PLC from FATEK, MCGS touch screens, which can ensure stable and continuous work of our machines. |  |

Clip In Ceiling Tile Production Line

KINGREAL can manufacture Clip In Ceiling Tile Production Line, which usually consists of decoiler, levelers, feeders, punch presses, hydraulic press bending forming machine and other components. The Clip In Ceiling Tile products are usually installed with Triangle Tee ( Spring Tee Carrier) to form a complete False Ceiling System. Metal Ceiling Tile Production Line and Triangle Tee Roll Forming Machine are the most common machines used in the building materials industry, and KINGREAL can customize them to meet the needs of our customers.

Clip In Ceiling System

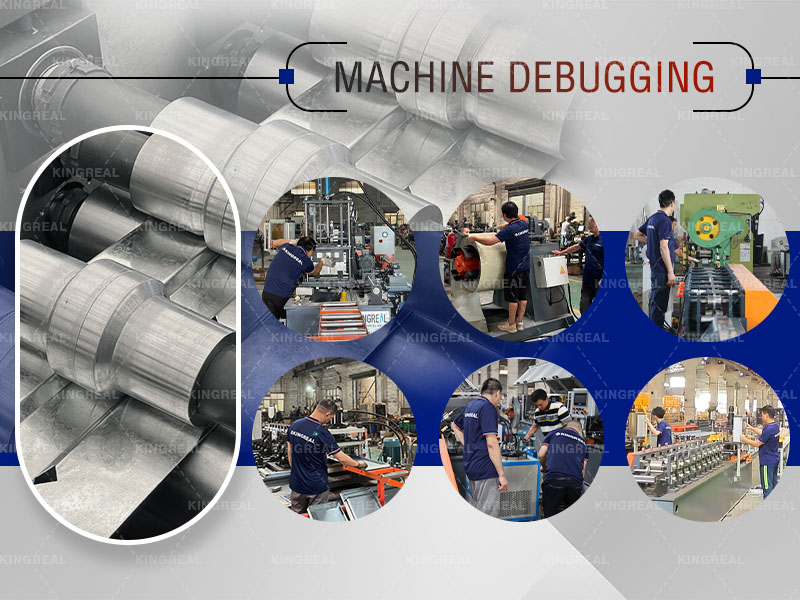

KINGREAL Technical Team

KINGREAL is not only integrating R&D, have our own technical team and factory, but also have many years of experience in the design and manufacture of Ceiling T Bar Making Machine. KINGREAL have successfully customized Metal Ceiling Carriers Production Line to meet the needs of customers in many countries. KINGREAL has established the localized technical support team in Netherlands, Chile, Russia, Bengal, Italy, USA and etc.. Localized service points in other countries are also in progress.