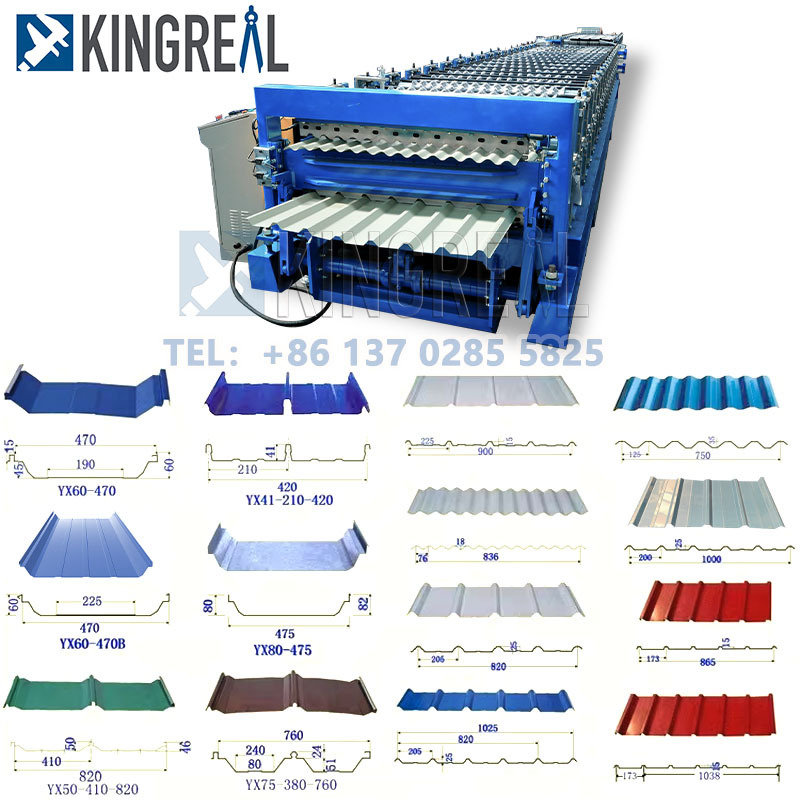

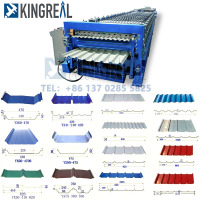

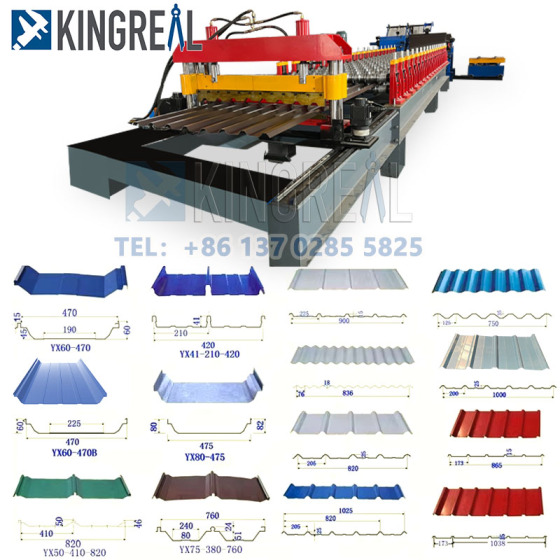

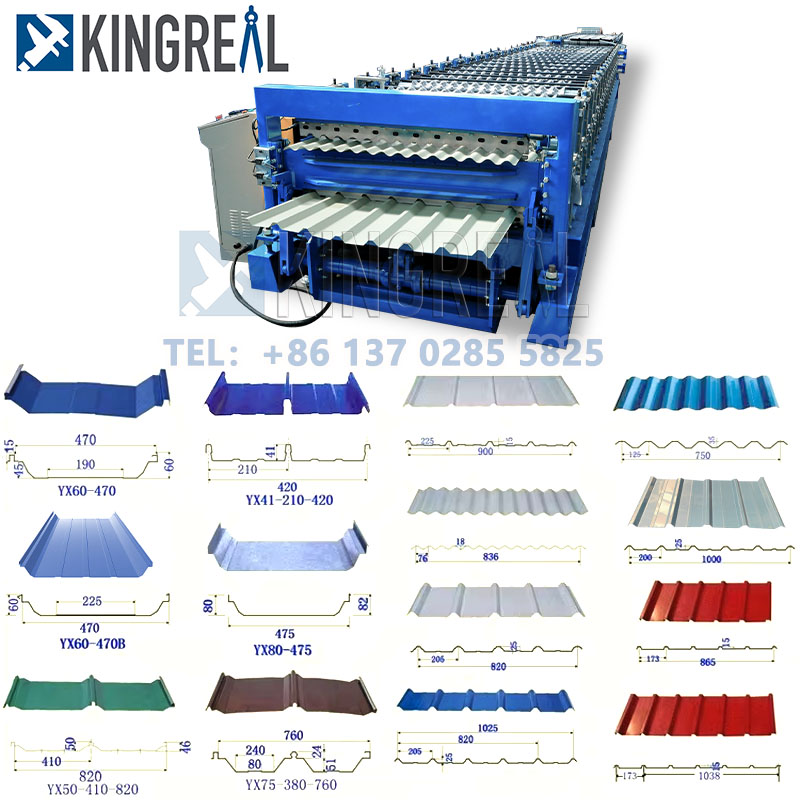

Corrugated Roof Sheet Forming Machine

KINGREAL Corrugated Roof Sheet Forming Machine is an advanced roof tile roll forming machine that produces corrugated roof tile with high speed.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Corrugated Roof Sheet Machine

Description of Corrugated Roof Sheet Forming Machine

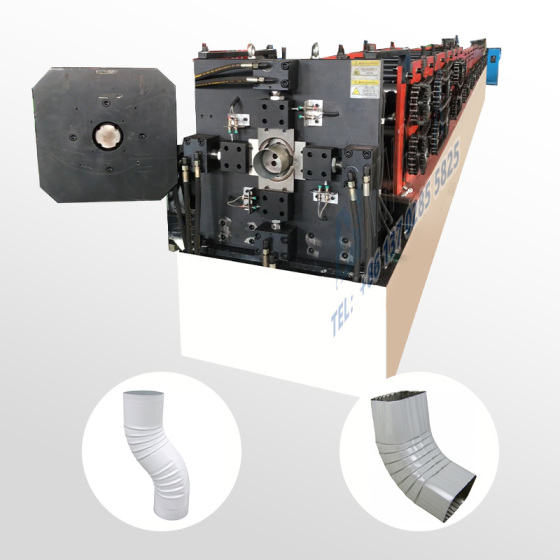

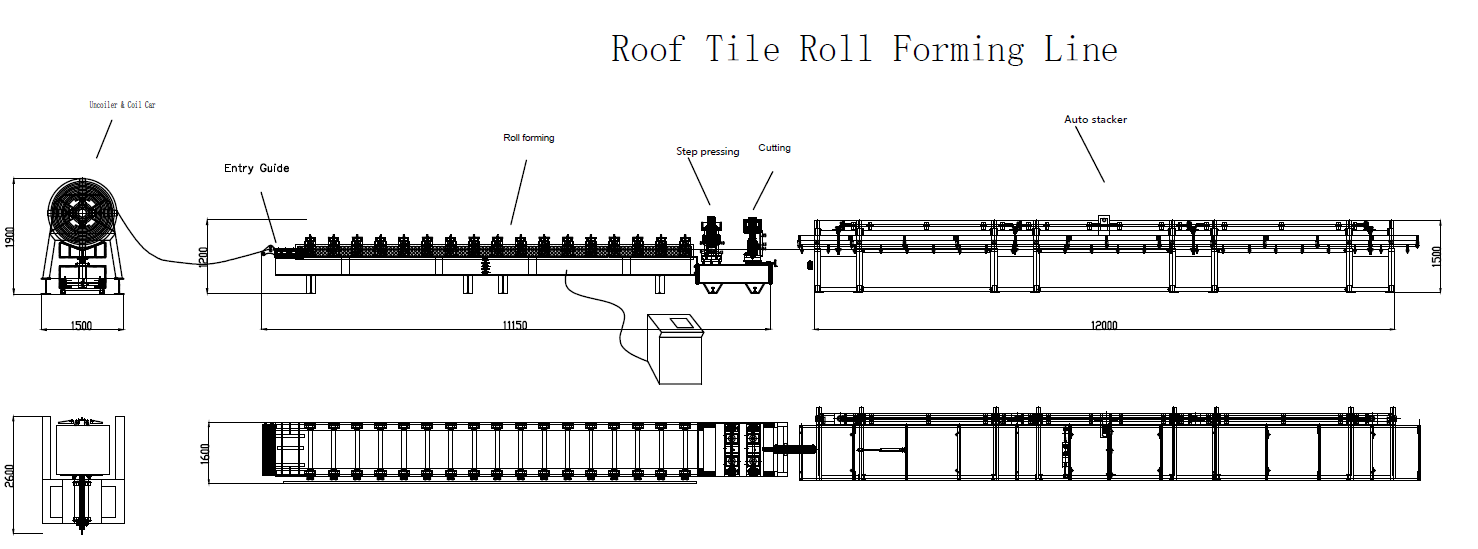

KINGREAL corrugated roof tile making machine is a specialized in the production and manufacture of corrugated roof tiles, using advanced technology and automation systems to efficiently produce high quality corrugated tile products. This corrugated roof tile making machine is a fully automatic production line for the roof corrugated roof panels. The machine includes Decoiler, straightener, servo feeder, punch press, cable tray cover main roll forming machine, shearing machine, automatic control system.

Technical Specification of Corrugated Sheet Manufacturing Machine

| Raw Material | Galvanized, Aluminum, PPGI and so on |

| Material Thickness | 0.3-0.8mm |

| Rollers’ Material | Steel #45 |

| Forming Speed | 20M/Min |

| Driving System | Chain Drive Or Hydraulic Drive |

| Cutting System | Post-cutting |

| Power Supply | 380V 50Hz |

| Frequency Changer Brand | Yaskawa |

Main Components of Corrugated Sheet Manufacturing Machine

- Decoiler

- Feeding Machine

- Main Roll forming Machine

- Hydraulic Cutting Station

- Out Put Table

Technical Specs

Equipment frame structure | 350H steel |

| Hanging board | square steel hanging board |

| Forming shaft material | 45# |

| Forming wheel material | bearing steel |

| Host motor | 5.5KW |

Equipment shearing power | 4KW |

Cutting off method | hydraulic cylinde |

Equipment working speed | 0-20m/min |

Blade material | manganese vanadium |

Features of Corrugated Roof Tile Making Machine

1. Stable: The Corrugated Roof Tile Making Machine has a sturdy structure and is made of high quality materials to ensure its stability and durability. Adopting advanced control system, it is capable of precise operation and adjustment to ensure the production of corrugated tiles in accordance with the specifications.

2. High efficiency: Equipped with efficient production line, it can produce corrugated tiles quickly and continuously to improve corrugated roof tile production efficiency.

3. High degree of automation: Equipped with automation function, capable of automatically completing the process steps of cutting, molding, coating and stacking of shingles, reducing manual operation and improving production efficiency.

4.Flexible production: With adjustable production capacity, capable of expanding or reducing the production line according to the demand, in order to meet the production demand of different scales.

Corrugated Roof Sheet Making Machine With Auto Packaging Unit

KINGREAL provides fully automated packaging solutions for customers' metal roof making machines, aiming to significantly improve production efficiency. This configuration not only optimizes the production process, but also effectively reduces the time and labor costs in operation.

The fully automated packaging machine can quickly and accurately pack the finished metal roof tiles after the corrugated roof sheet making machine is completed. Compared with the traditional manual baling method, the automated packaging unit has obvious advantages in speed and consistency. It can complete a large number of packaging tasks in a short time, reducing the instability and human errors caused by manual operation, thereby ensuring the consistent packaging quality of each batch of products.

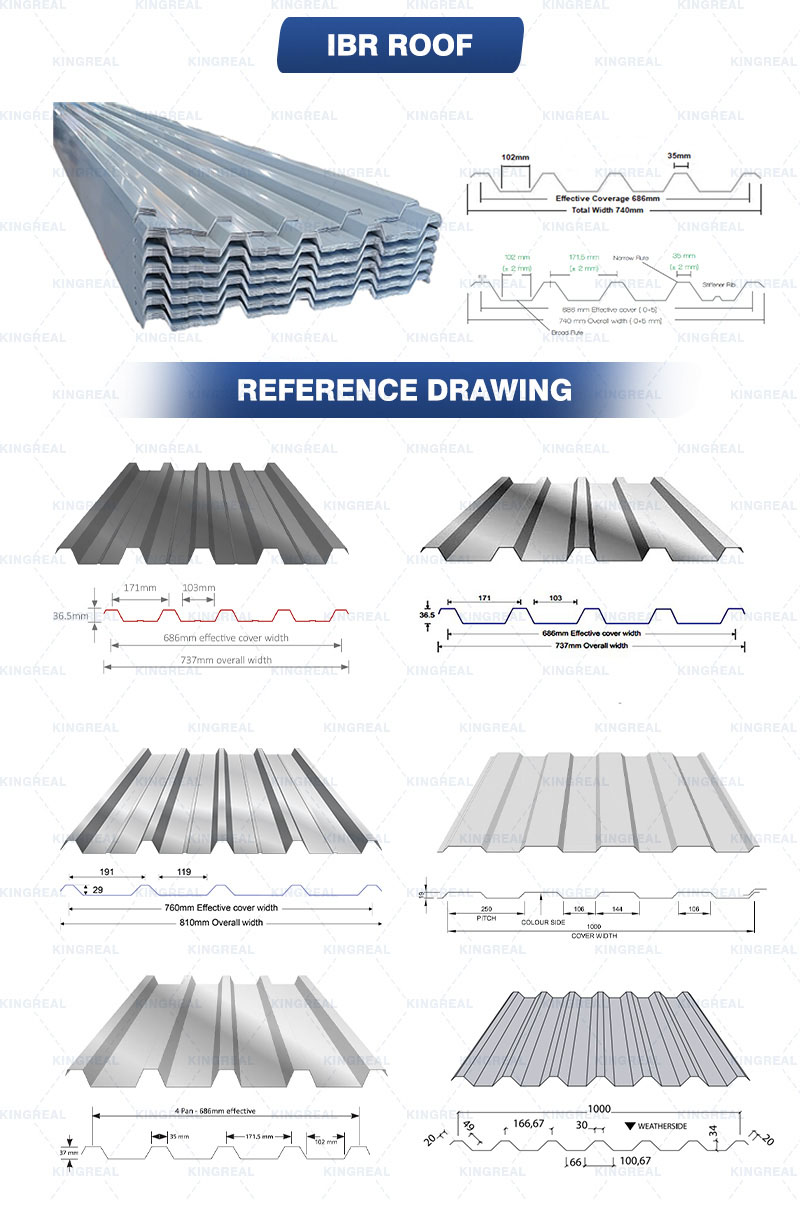

What is Corrugated Roof Tile?

Corrugated roof tiles offer several notable features that make them a popular choice for roofing:

1.Light in Weight: They are relatively light, weighing between 6–14 kg/m², which is about 1/30th the weight of a brick wall

2.Excellent Corrosion Resistance: Made of color-coated steel, these tiles provide superior corrosion resistance and can last more than 30 years.

3.High Strength: Corrugated roof tiles are known for their high strength and resistance to damage or tearing.

4.Widely used: corrugated roofing is versatile and can be adapted to fit any roof size or shape due to its wave-like design. It’s also designed to withstand harsh weather conditions like high winds, heavy rains, or hail. When installed on a slope, corrugated metal roofing systems are particularly effective at shedding water quickly.

KINGREAL Technical Team

KINGREAL is not only integrating R&D, have our own technical team and factory, but also have many years of experience in the design and manufacture of Corrugated Roof Tile Roll Forming Making Machinery. We have successfully customized Corrugated Roof Tile Roll Forming Making Machines to meet the needs of customers in many countries.

KINGREAL has established the localized technical support team in Qatar, India, Saudi Arabia, USA, Egypt and etc.. Localized service points in other countries are also in progress.

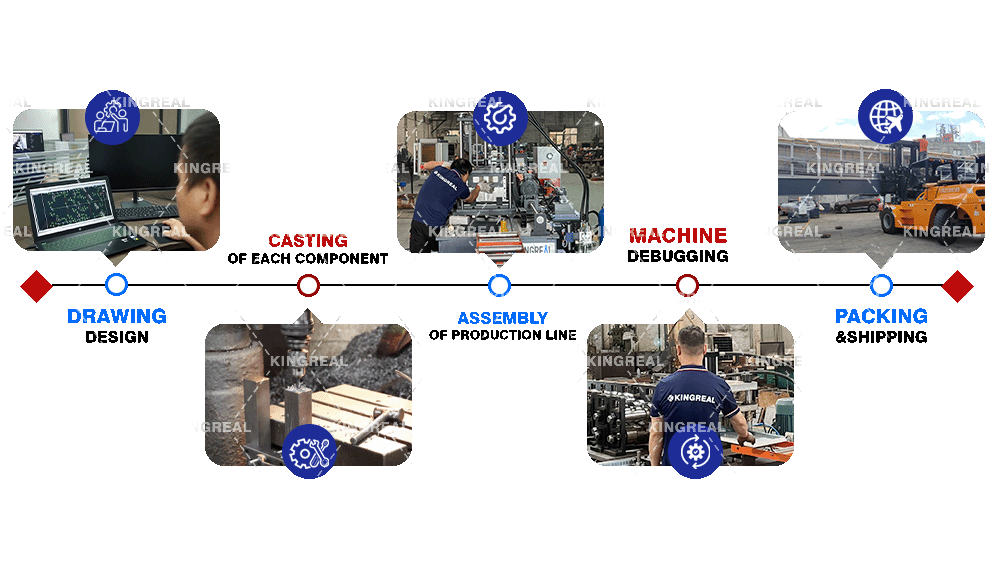

Roll Forming Machine Process