Downspout Roll Forming Machine

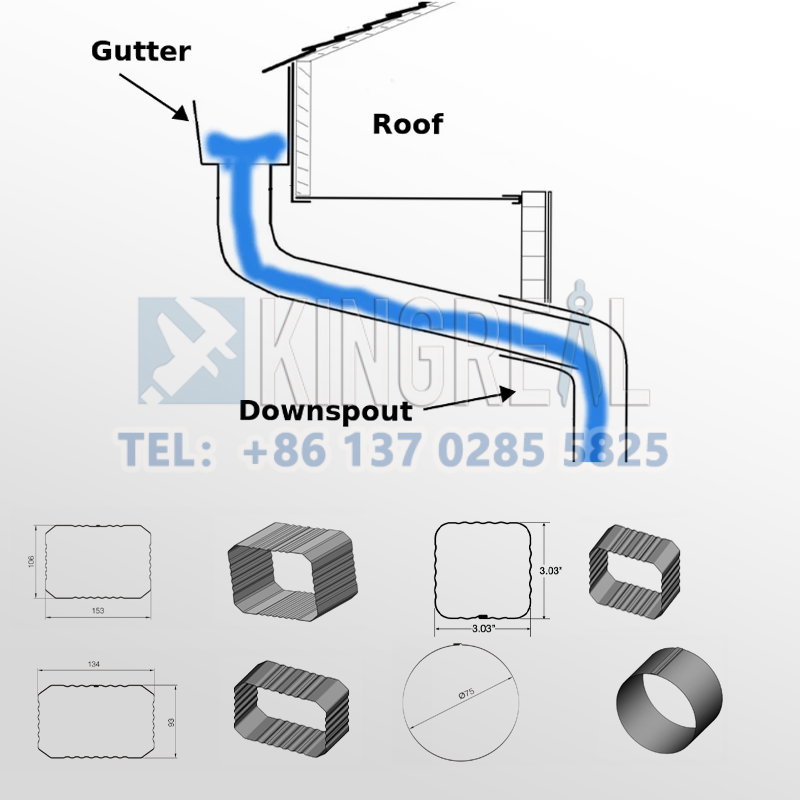

KINGREAL Downspout Roll Forming Machine is also known as downpipe roll forming machine, which is designed to efficiently and accurately produce Rectangular downspouts or round downspouts of customized lengths from metal coils. Downspouts are bridges used to drain rainwater from the gutter into the local rainwater pipes. Downspouts complement the metal roof tile system and together form the overall drainage system of the building.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Downspout Roll Forming Machine

Introduction of Downspout Forming Machine

KINGREAL downpipe roll forming machine is a kind of equipment specially used for manufacturing precise and well-sealed downspouts. The main function of downpipe is to effectively guide rainwater discharged from rain gutters to the ground, prevent water flow from flooding the foundation of the building, and ensure the safety and durability of the building.

KINGREAL downpipe roll forming machine can be customized according to the specific requirements of customers. Engineers will understand the actual needs of customers in detail, including specifications, raw materials, and expected production speed. This personalized service ensures that each downspout forming machine can meet the specific application needs of customers and provide the best production efficiency and product quality.

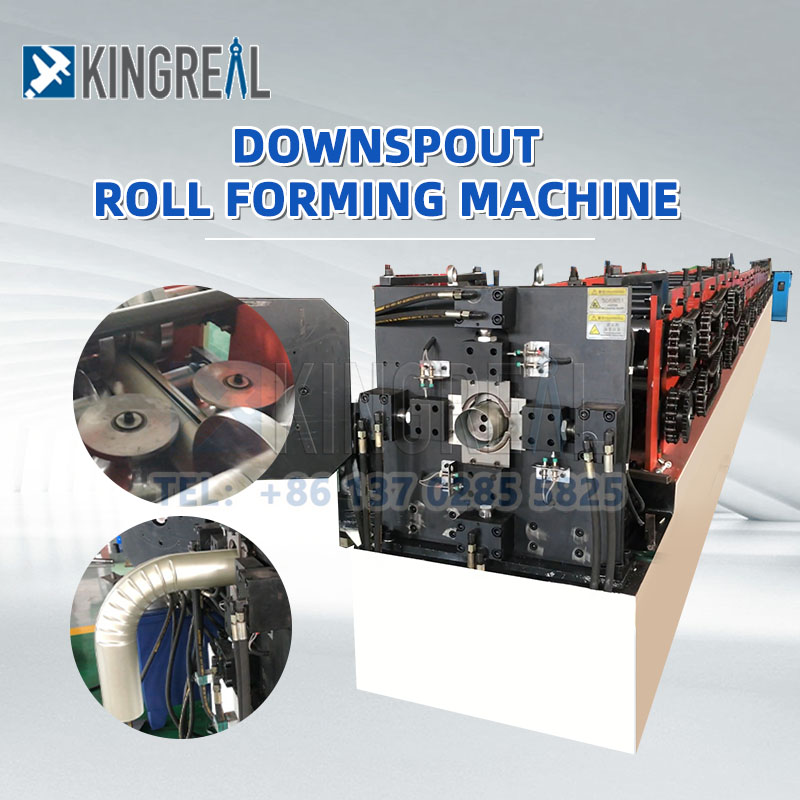

During the production process, KINGREAL downpipe roll forming machine produces seamless and consistent downpipes in an efficient manner, which are widely used in various construction projects.

Before leaving the factory, KINGREAL downspout roll forming machine will undergo rigorous installation and testing to ensure that each downspout forming machine can meet high standards of production requirements. At the same time, KINGREAL will also provide customers with detailed operation guides and corresponding video tutorials so that customers can get started quickly. If necessary, KINGREAL will also send professional engineers to the customer's factory for guidance and training to ensure that customers have no worries when using the downspout roll forming machine.

Workflow of Downspout Forming Machine

Decoiler -- Main Roll Forming Machine -- Bending & Cutting Station -- Run Out Table

1. Feeding: First, large rolls of metal coils are fed into the machine as raw materials for manufacturing downpipes. The downpipe roll forming machine can handle metal coils of various materials, including galvanized steel, color-coated steel, etc., to meet the needs of different customers.

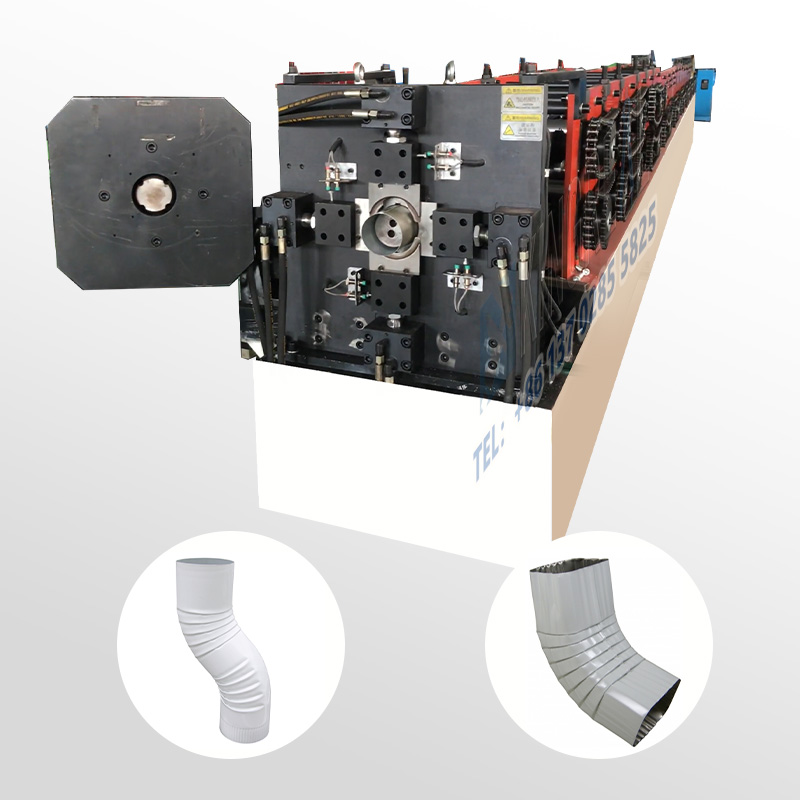

2. Forming process: The downspout forming machine processes metal coils through a series of precision rollers, dies and forming mechanisms. Through a multi-stage forming process, the downspout roll forming machine can shape the metal into the required downpipe shape, including rectangular, circular or other custom designs.

3. Bending & Cutting: After the forming is completed, the cutting mechanism equipped with the machine cuts the downpipe into the required precise length to ensure that each product meets the installation requirements. The cutting process adopts the die shearing method to ensure a smooth cut and reduce the trouble of subsequent processing.

4. Output: Finished downspouts are usually extruded directly from the downspout forming machine to form seamless lengths. These finished products can be immediately packaged and shipped, or installed directly on the building, which improves production efficiency.

Parameters of Downpipe Roll Forming Machine

| Electric motor power of forming machine | 3KW |

| Electric motor power of hydraulic tank | 5.5KW |

| Roll stand | 19 level rollers and a series of vertical rollers |

| Thickness of rolling material | 0.5-0.6 mm/color steel |

| Roller material | high-quality45steel |

| Control system | adopting Siemens PLC control system |

| Shear mode | adopting mould shear after being formed |

| Dimension of forming machine | 17000 mm – 1200 mm – 1400 mm |

Features of Downspout Forming Machine

Seamless design

The biggest advantage of KINGREAL downpipe roll forming machine is its ability to manufacture seamless downpipes. This seamless design significantly reduces the risk of rainwater leakage, ensuring that rainwater can flow smoothly and avoiding water damage caused by leakage at the pipe joints. In addition, seamless downpipes are more beautiful in appearance, adding a neat and high-end feel to the building.

Seamless downpipes produced using KINGREAL downspout roll forming machine also excel in durability. Since there are no seams, the downpipes are more stable when subjected to water flow pressure, reducing damage caused by fatigue at the joints. This means that the maintenance costs of buildings using seamless downpipes will be significantly reduced during long-term use, and owners can enjoy longer service life and less maintenance troubles.

In addition, the seamless design of the downspout forming machine makes the installation process simpler. Traditional seamed downpipes need to be butt-jointed during installation, which may cause leakage due to improper butt-jointing. The seamless downpipes produced using KINGREAL downpipe roll forming machine eliminate this process, reduce the complexity of construction, and improve construction efficiency.

Customized service

Another major advantage of KINGREAL downspout roll forming machine is that it provides comprehensive customized services. According to the specific needs of different construction projects, the downspout forming machine is able to produce downpipes of various sizes and styles to meet the various requirements of customers.

If customers have special style requirements, they can provide design drawings to KINGREAL engineers. The team will design the downpipe roll forming machine according to the customer's requirements to ensure that the downpipes that meet the expectations can be produced. This tailor-made service not only improves customer satisfaction, but also effectively solves problems encountered when standardized products cannot meet the requirements. Whether it is a special shape, size or material, KINGREAL downspout forming machine can provide corresponding solutions to help customers realize their design concepts.

In addition, customized services also include designs for specific environments. For example, in some extreme weather conditions, the design of downpipes may need to consider stronger pressure resistance or better corrosion resistance. KINGREAL can select appropriate materials and manufacturing processes according to customer needs to ensure that the finished products produced by the downspout roll forming machine can be used normally in specific environments.

Efficient production

KINGREAL downpipe roll forming machine is extremely efficient in the production process and can produce downpipes quickly and consistently. The design and technical optimization of the downspout forming machine enable the production line to complete a large number of production tasks in a short period of time, ensuring that customers can get the downpipes they need in a timely manner.

This efficient production capacity not only saves time, but also significantly reduces labor costs. Traditional production methods may require a lot of manpower and time to complete, while KINGREAL downpipe roll forming machine greatly reduces the reliance on manual labor through automation and advanced technology, making the production process smoother and more efficient. This means that companies can deliver more downspouts in a shorter time, thereby improving market competitiveness.

In addition, efficient production also means lower operating costs. As production efficiency improves, the cost per unit product decreases, and companies can convert the cost savings into more competitive prices to attract more customers. This virtuous cycle not only improves the profitability of the company, but also provides customers with more cost-effective downpipes.

Application of Downspout Roll Forming Machine

Rectangular downspouts vs Round downspouts:

| Shape | Rectangular | Round |

| Flow | More advantages in visual effects and space utilization | More suitable for fast flow |

| Aesthetics | Usually more in line with modern architectural styles | More classic |

How Do Downspouts and Metal Roof Tiles Form a Complete System?

In buildings, downspouts and ,metal roof tiles and other components together form a complete rainwater drainage system, ensuring that rainwater is smoothly guided from the roof to the ground to prevent water damage and structural damage. Metal roof tiles, ridge cap tiles, gutters, downspouts and floor decking complement each other and together form an efficient rainwater drainage system. Metal roof tiles and ridge cap tiles are responsible for guiding rainwater, gutters are responsible for collecting rainwater, downspouts are responsible for draining rainwater, and floor decking provides support for the entire system. Through reasonable design and installation, these components ensure the safety and durability of the building during rainfall and effectively prevent the occurrence of water damage problems.

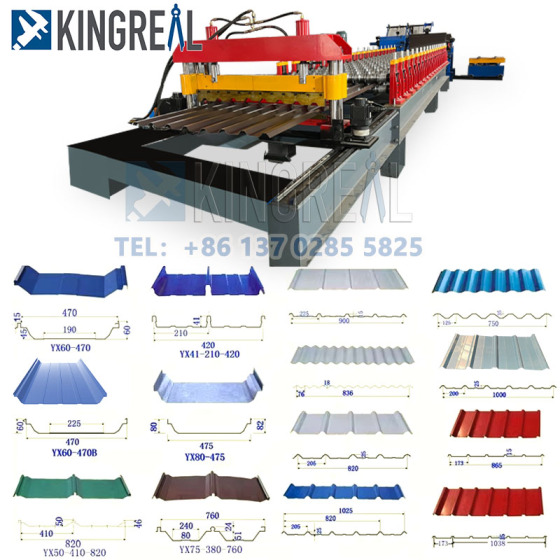

KINGREAL can provide the above machines, various types of metal roof sheet making machines, ridge cap roll forming machines, gutter making machines, downpipe roll forming machines and floor deck roll forming machines. Provide customers with corresponding machines to form a complete metal roof tile system.