Roof Sheet Making Machine

KINGREAL roof sheet making machine can produce different types of roof tiles, with the advantages of fast forming speed, large output, reliable performance, automation and easy operation.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Roof Sheet Making Machine

Description Of Roof Sheet Making Machine

KINGREAL roof sheet making machine is specially used to manufacture metal roof tiles. Metal roof tiles are an economical solution with good high temperature resistance and are in great demand in markets such as Africa. Compared with traditional concrete roof tiles or asphalt roof tiles, metal roof tiles are lighter and more durable, and can effectively cope with various climatic conditions.

KINGREAl can provide customers with a variety of metal roof tile solutions. KINGREAL roof tile making machine has the characteristics of fast operation speed, high production precision and durability.

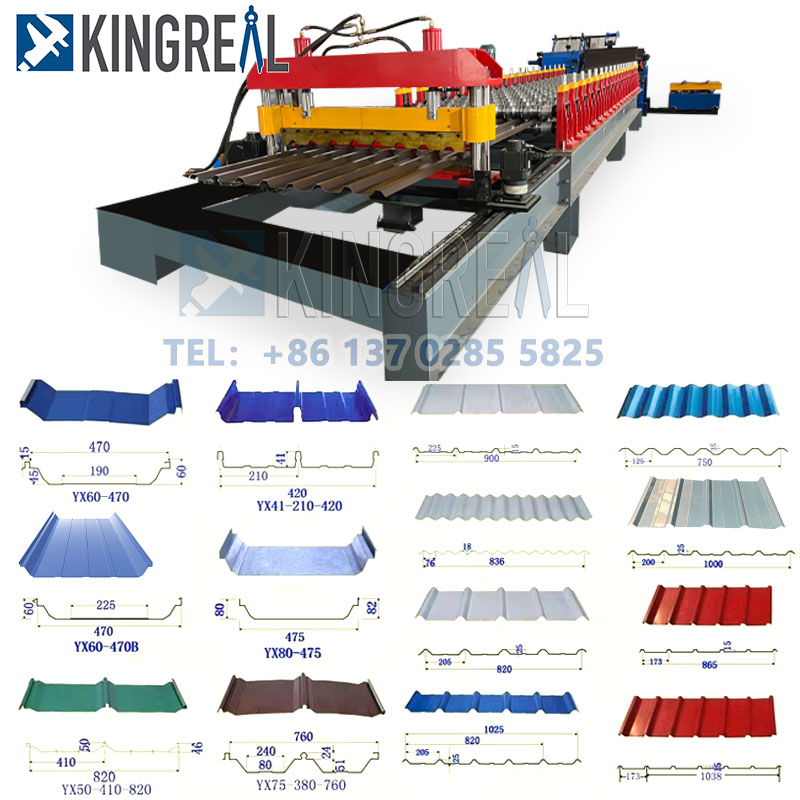

Different Types Of Metal Roofing Machines

KINGREAL provides a variety of roof tile making machines, you can choose according to actual production needs. If you need more relevant metal roofing machine information, please feel free to contact KINGREAL, including but not limited to the following roof sheet making machines:

- Double layer roof tile machine

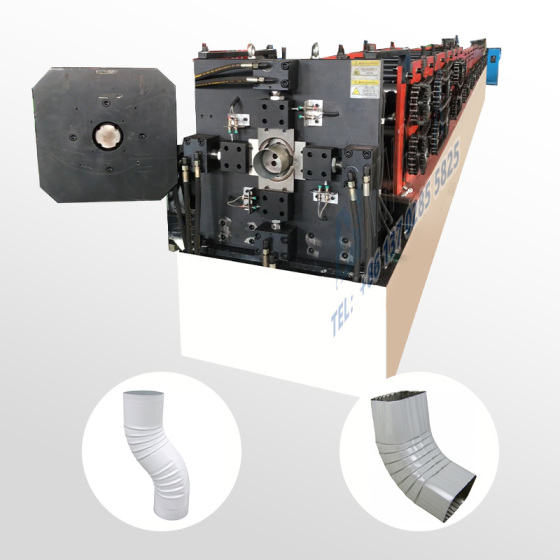

- Downspout roll forming machine

- Gutter roll forming machine

- Metal deck roll forming machine

- Standing seam roof panel machine

- Metal roof ridge cap machine

- Snap lock roof panel machine

- R panel machine

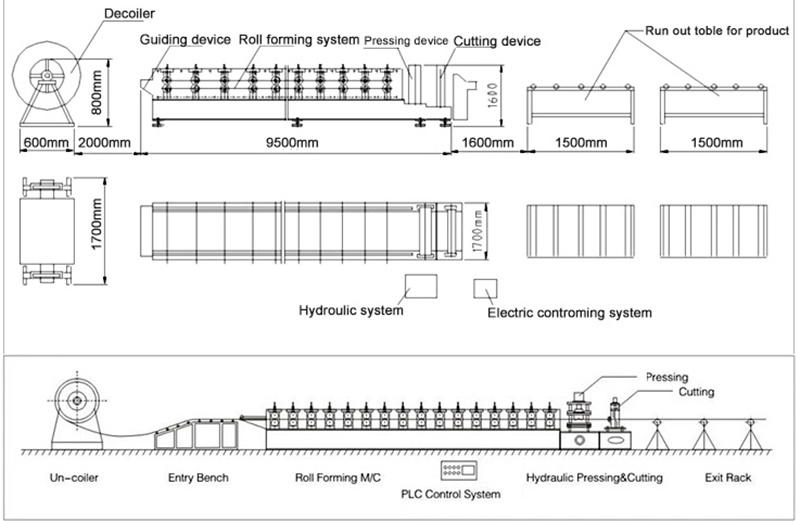

Workflow Of Roof Tile Making Machinet

Decoiler -- Guiding Device -- Roll Forming Machine -- Cutting Device -- Run Out Table

Features Of Metal Roofing Machine

Decoiler

KINGREAL roof tile making machine is equipped with an efficient automatic decoiler with the ability to quickly uncoil, which can significantly improve production efficiency. This design not only saves labor costs, but also ensures a smooth supply of materials, reduces potential risks during operation, and improves overall work safety.

High-quality rollers

The forming roller has undergone multiple precision machining to ensure its wear resistance and durability. This high-quality roller design can maintain stable performance during long-term production, reduce replacement frequency and maintenance costs, thereby improving the overall service life and production efficiency of the metal roofing machine.

Independent archway

The structure of the roll forming machine is composed of independent archways, which can effectively ensure the smooth operation of the roof tile making machine. The independent archway structure not only enhances the stability of the metal roofing machine and reduces vibration, but also ensures safety during high-speed operation, and improves the consistency and quality of the product.

Cutting system

The cutting system achieves precise roof tile cutting, and the flatness and neatness of the cutting surface meet high standards. The cutting length strictly follows the set parameters to ensure that the size of each metal roof tile is consistent and meets the specific needs of customers.

Advantages Of Metal Roofing Machine

Wear-resistant and durable rollers

The rollers have been precision-processed many times, and have excellent wear resistance and durability, which significantly extends the service life of the roof tile making machine. This design can reduce maintenance frequency, reduce production costs, and improve overall work efficiency.

Ability to handle a variety of metal materials

KINGREAL metal roofing machines can handle a variety of metal raw materials, including stainless steel, galvanized aluminum and aluminum profiles. This flexibility allows customers to choose the right material according to specific needs to meet the requirements of different markets.

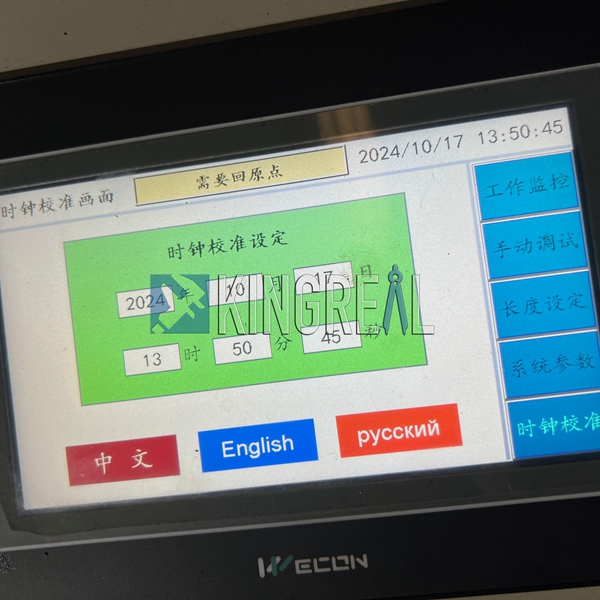

High-precision control system

KINGREAL roof tile making machines use PLC-controlled electric servo drives to ensure high-precision production. Users can easily program through the touch screen to quickly adjust the length and production quantity of the required metal tiles, which improves the convenience and efficiency of operation.

Customized design

KINGREAL engineers can design roof sheet making machines that meet specific needs based on the drawings and cutting shapes provided by customers. This customized service ensures the equipment's effectiveness and customer satisfaction, meeting the specific needs of different industries.

Unique Design -- Metal Roofing Machine With Auto Packaging Unit

According to market research, manufacturers of metal roof tiles have high requirements for the speed of the entire production process and expect to produce enough metal roof tiles in the shortest time. To this end, KINGREAL engineers equipped the fully automated metal roofing machine with a packaging machine. After production is completed, the metal tiles will be automatically transported to the packaging unit for packaging and stacking. This design bids farewell to the traditional manual handling and packaging method, saving time and labor costs. At the same time, the biggest advantage of the automated packaging machine is that it always maintains high efficiency and will not reduce speed due to fatigue, thereby ensuring the continuity and stability of the production process.

Application Areas Of Roof Tiles

Metal roof tiles are widely used in various types and styles of architectural designs. They have the characteristics of fast installation, which can effectively shorten construction time and improve work efficiency.

Metal roof tile:

- Light material and high strength

- Anti-corrosion and rust-proof, not easy to oxidize

- Strong sealing and waterproof

- Fast paving speed and shortened construction time

Customer Visit

KINGREAL warmly welcomes customers to visit KINGREAL's factory and experience the production process and equipment performance of KINGREAL roof tile making machines. In order to ensure that customers obtain comprehensive information during the visit, KINGREAL will send professional staff to accompany the whole process, answer your questions, and introduce KINGREAL's metal roofing machines and their functions in depth.

Visit process:

1. Full accompaniment

KINGREAL's professional team will accompany customers to visit the factory, introduce the working principle and technical characteristics of the roof tile making machine in detail, so that you can have a deeper understanding of KINGREAL's products.

2. Machine demonstration

On site, customers will personally observe the operating status of the roof tile making machine, and even participate in the actual operation to experience the efficiency and stability of KINGREAL roof tile making machines.

3. One-to-one program discussion

After the visit, KINGREAL will invite customers to the conference room for a one-to-one communication with KINGREAL engineers. According to the drawings provided by the customer and the actual production needs, the engineer will develop a tailor-made machine manufacturing plan for the customer. KINGREAL knows that each customer's needs are unique, so KINGREAL's team will do their best to provide you with the best solution.

4. Personalized service

During the discussion, customers can raise any questions or special requests, and KINGREAL's engineers will adjust according to your feedback to ensure that the final solution fully meets your expectations.

If you want to know more about the case of metal roofing machine, please click KINGREAL Roof Tile Machine In South Africa.