Double Layer Roll Forming Machine

The double layer metal roof panel products are formed by Double Layer Roll Forming Machine from high quality metal sheet or metal coil, the features of the machine are light, strong strength and long lasting service life.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

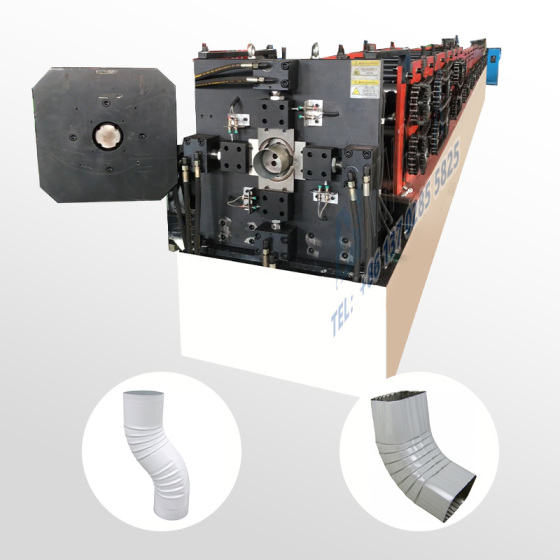

Description of Double Layer Roll Forming Machine

KINGREAL Double Layer Roofing Sheet Roll Forming Machine is a highly efficient production machine with a unique design that enables it to produce two metal roof tiles at the same time. The metal roof machine utilizes advanced processes and technologies for fast, precise and reliable production capacity.

The metal roofing machine double layer structure enables it to handle to manufacturing process of two metal roof tiles at the same time, which greatly improves production efficiency. It has two independent production lines inside, each with the processes of forming, cutting and cooling the metal tiles. This parallel operation allows the machine to carry out two production processes simultaneously, thus halving production time.

Specification of Double Layer Roof Tile Roll Forming Machine

Raw Material | PPGI/GI |

Middle Plate | 18mm |

Wheel | 45# steel, hardness HRC 58-60℃ |

| Shaft | high quality 45# forged steel, with anti-return pad |

Shearing knife | Cr12 / Cr12MOV, heat treatment, HRC 58-60℃ |

Main motor power | 5.5KW |

| Productivity | Up: 1.5-3m/min Down: 8-12m/min |

Control System | PLC Control System, 360 degree rotation |

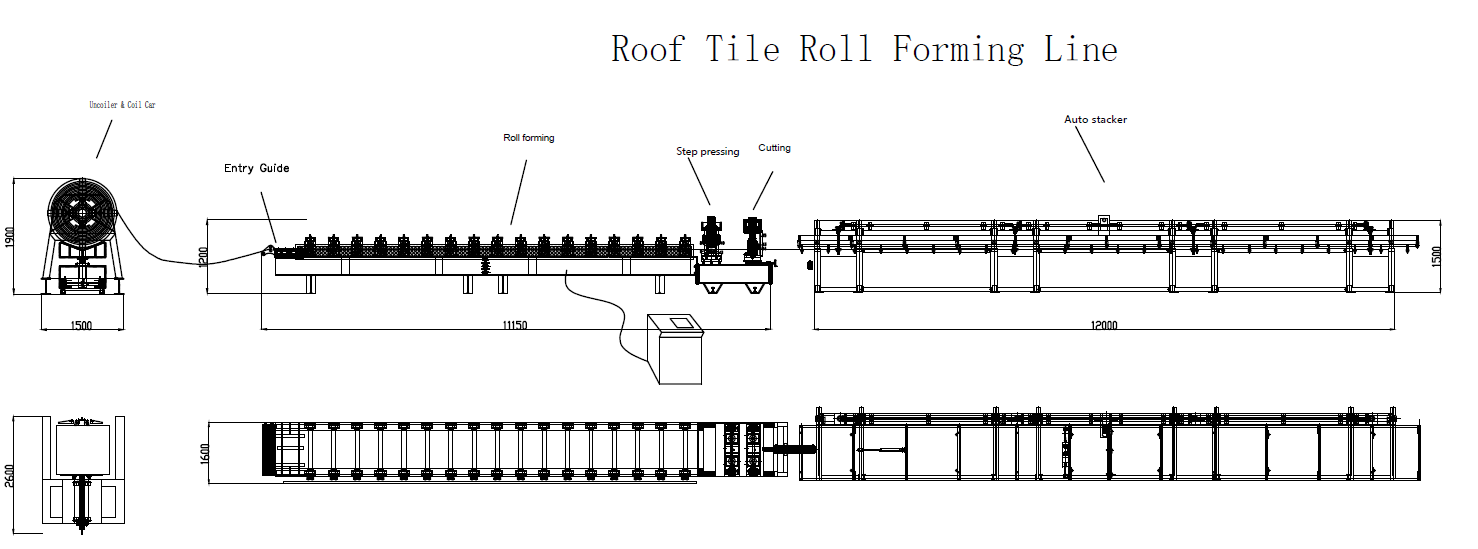

Main Processes

Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting - Finished Metal Roof Panel Out Put

Technical Specs

| Number of forming rows | Upper 16 rows Lower 16 rows |

| Machine body structure | 350H steel |

| Size of forming shaft | 80mm |

| Material of moulding wheel | bearing steel |

| Motor of main machine | 5.5KW |

| Shear power | 4KW |

| Working speed | 0-20m/min |

| Blade material | manganese vanadium |

| Cutting method | hydraulic |

Features of Double Layer Roofing Sheet Roll Forming Machine

1. High degree of automation

The double layer roof tile making machine has a high degree of automation. It is equipped with advanced control system and sensors, which can monitor and adjust the parameters in the production process in real time to ensure that the quality and size of each metal tile meet the requirements. At the same time, the roofing machine also has the function of automatic loading and unloading, which reduces the need for manual operation and improves production efficiency and safety.

2.Flexible production capacity

Kingreal double layer roofing sheet roll forming machine also has flexible production capacity. It can adjust the speed and process parameters of the production line according to the user‘s needs in order to adapt to the manufacture of different types and specifications of metal roof panel. This flexibility enables the sheet metal roofing machine to meet the diversified demands of the market and provide customized production services.

3.Higher economic efficiency

Since a double-layer metal roof tile machine can produce two metal roof panel at the same time, a Double Layer Metal Steel Roof Tile Forming Machine saves on the purchase and maintenance costs of one machine compared to using two single-layer metal tile machines. This means lower investment costs and higher production efficiency for companies.

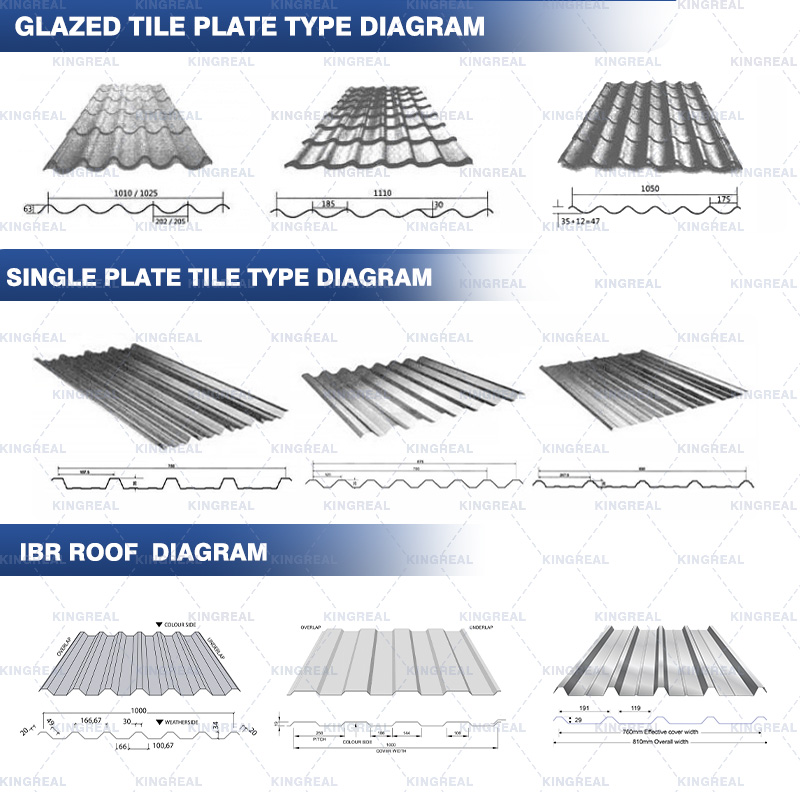

Application of Double Layer Metal Roof Sheet

The application scope of double layer metal tile machine covers many fields such as construction, agriculture, industry, transportation and so on, which can meet the needs of different industries for metal tiles. Its high efficient production capacity and excellent product quality make it an ideal choice for various industries.

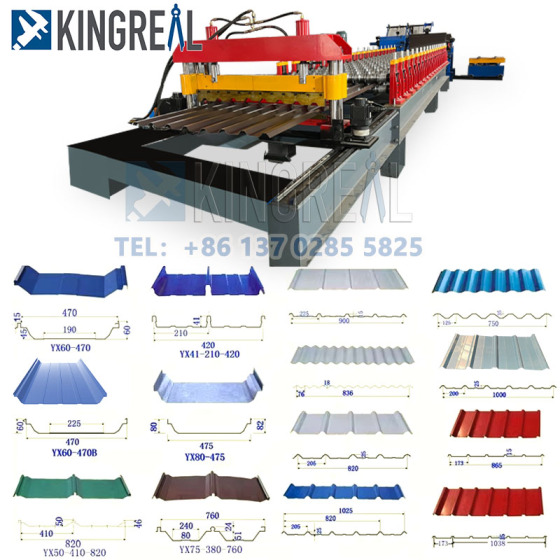

What Our Machine Can Produce

Technology Support

As a professional manufacturer of metal roofing roll forming machine in China, KINGREAL has been in design - production - installation - after-sales for more than 20 years. KINGREAL is able to customize production solutions according to customer‘s drawings and specific parameter requirements.

After you ordered, our technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.