PV Support Bracket Roll Forming Machine

KINGREAL PV support bracket production line can produce anti-vibration bracket series products, including 41 × 21, 41 × 41, 41 × 52, 41 × 62 and other specifications.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Description Of PV Support Bracket Forming Machine

KINGREAL PV support bracket production line can produce anti-vibration bracket series products, including 41 × 21, 41 × 41, 41 × 52, 41 × 62 and other specifications. The pv mounting brackets cold roll forming equipment produced by our company has the following advantages:

1. The equipment control is PLC control, and multiple safety protection is set during normal production.

2. The PV support Bracket production line is a fully automated production line for Decoiler, guiding feeding, leveling, high precision roll forming, fixed length cutting and receiving of fixed size steel strip.

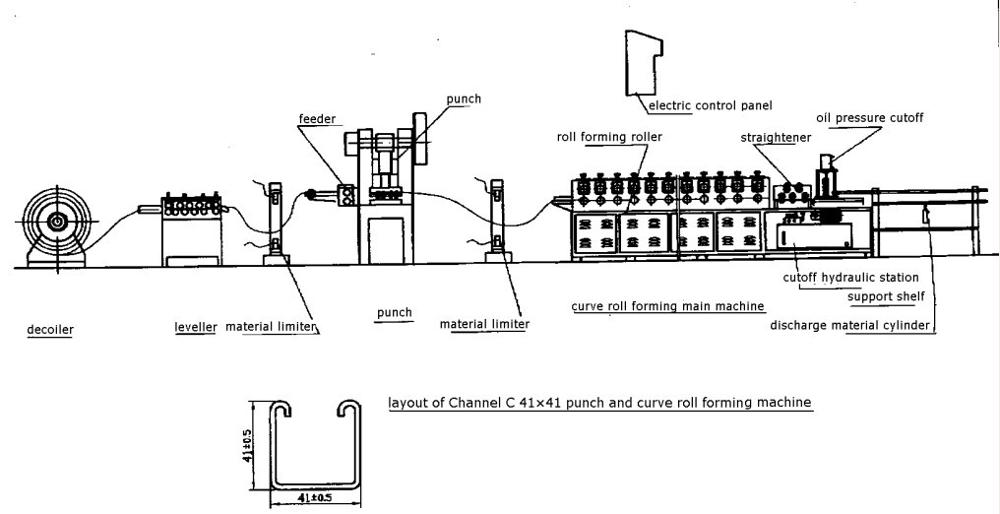

Working Process

PV support bracket roll forming process Uncoil – leveling – pinch, punching – forming – length, cut – receiving equipment

Technical Performance

| sheet thickness | 2.0-3.0 mm line |

| working speed | 15-20 m/min |

mainframe forming speed | 10 – 15 m/min |

| Production area | 30m long × 3m wide |

Total capacity | 60 kw |

The main technical parameters

| Ordinary inner | tensioning rack 300mm, bearing 5T, inner diameter 460-520mm |

| Feed width | 110mm |

| Number of rollers | 15 tracks |

| Rolling speed | 8-15m/min |

| Spindle material | 45# steel, modulation treatment |

Roll material | Gcr15, quenched 55-58°, blackened surface |

Roller diameter | Φ80mm |

| Host power | 15KW turbine reducer |

Hydraulic pump station power | 5.5kw |

New Design: PV Support Bracket Machine With Auto Packaging Unit

In order to maximize the production efficiency of customers and meet the needs of automated production, KINGREAL engineers equipped the pv support bracket roll forming machine with an automatic packaging machine.

After the photovoltaic bracket is manufactured, the finished product will be directly transported to the automatic packaging unit for packaging and stacking. This process reduces the time and manpower required for traditional manual packaging, significantly reducing labor costs. At the same time, the efficient operation of the automatic packaging machine ensures the consistency and quality of the packaging, further enhancing the market competitiveness of the product.

Through this solution, customers can not only save time costs, but also effectively improve the overall operating efficiency of the production line and achieve higher production standards.

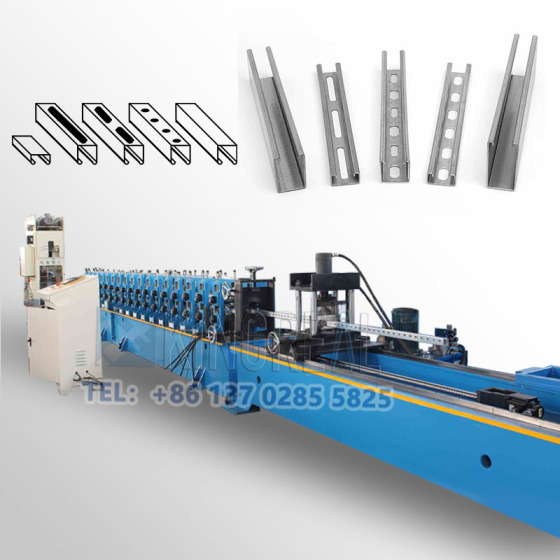

Product Display

KINGREAL solar panel bracket machine can produce finished products of various sizes, including 41 x 21 mm, 41 x 41 mm, 41 x 62 mm, 41 x 82 mm, etc. Common photovoltaic brackets are made of galvanized sheet with a material thickness ranging from 1.5-2.5mm, which is corrosion-resistant and durable.

Solar Post Unistrut Channal Application

The PV support brackets that the KINGREAL solar panel bracket machine can produce play a vital role in the construction of solar panel frames and mounting systems and are widely used in residential and commercial buildings, solar power plants, agricultural applications, transportation infrastructure and other fields.

Different Types of Struct Channel Production in One Machine

For more than 20 years of accumulation, KINGREAL has been focusing on design - production - installation - after-sales. KINGREAL is able to customize production solutions according to customer‘s drawings and specific parameter requirements and stocked many successful customized roll forming machine cases.

Quality Insurance

KINGREAL has established a strict quality control process to ensure that every production step meets the standards and requirements. This includes raw material procurement, production process, assembly, testing, etc. To ensure that every part of the machine meets quality standards.

It has also passed the international CE certificate certification.