Solar Mounting Strut Channel Machine

KINGREAL solar mounting strut channel machine is a special equipment for manufacturing metal profiles for solar mounting strut channel structures of different sizes.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Video About Solar Mounting Strut Channel Machine

Definition Of Solar Mounting Strut Channel Machine

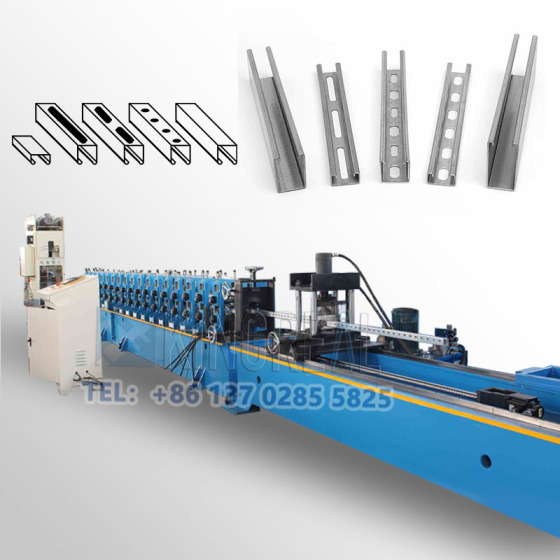

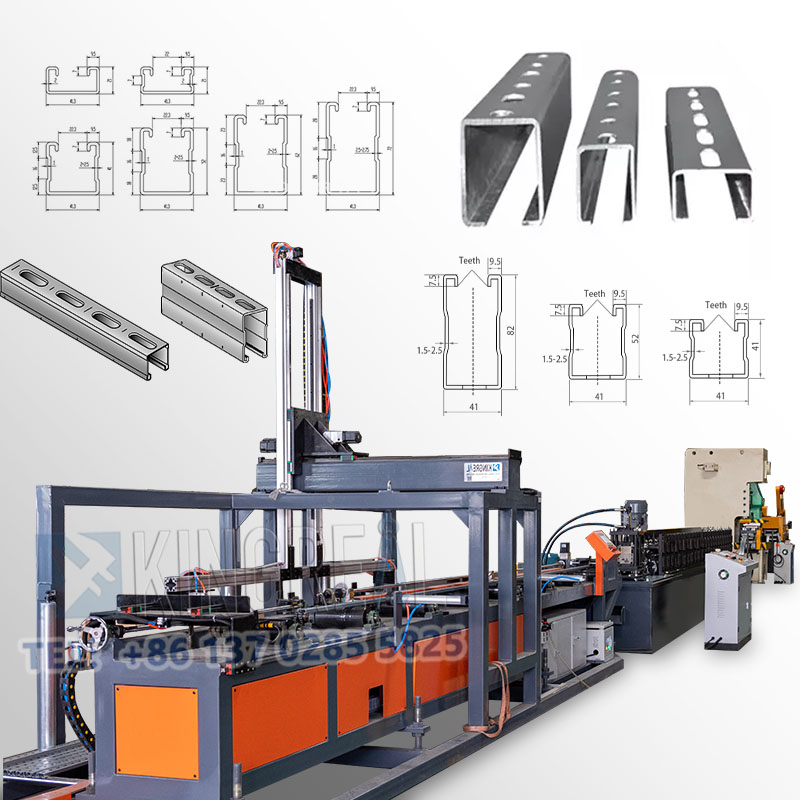

KINGREAL solar mounting strut channel making machine is an efficient equipment that can produce solar mounting strut channels of various sizes, including 41 × 21 mm, 41 × 41 mm, 41 × 62 mm, 41 × 82 mm, etc. These brackets are widely used in solar photovoltaic systems to provide solid support for photovoltaic modules.

The common material of photovoltaic brackets is galvanized sheet, which has good corrosion resistance and durability. The material thickness usually ranges from 1.5 mm to 2.5 mm, ensuring the stability and reliability of the bracket under various environmental conditions.

The photovoltaic bracket is produced through a series of work processes such as unwinding, leveling, punching, forming, and cutting of the solar mounting strut channel production line.

Main Components Of Solar Mounting Strut Channel Making Machine

2 -in-1 Decoiler & Straightener

It is designed to reduce installation space and the transition link in the straightening process of metal materials. This design not only improves the overall efficiency of the solar mounting strut channel production line, but also ensures the flatness of the material when entering the subsequent processing link, reducing production problems caused by uneven materials.

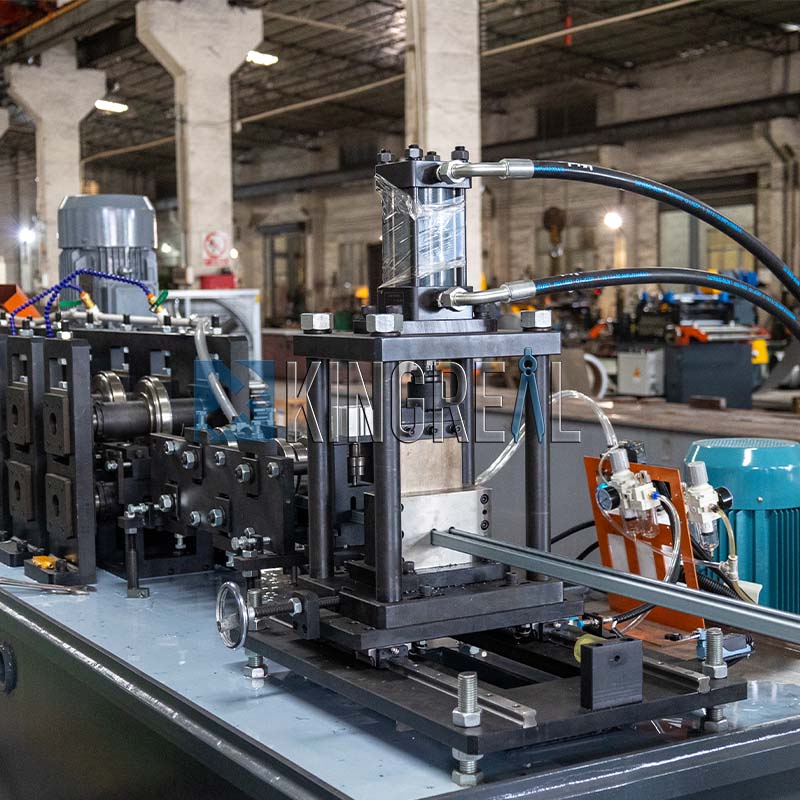

Punching station

The punching station uses equipment from a well-known brand (Yangli), which ensures stability and consistency during the punching process. In addition, the punching mold made of high-quality steel by KINGREAL has good durability and high precision, which can meet the punching needs of different specifications of solar mounting strut channels.

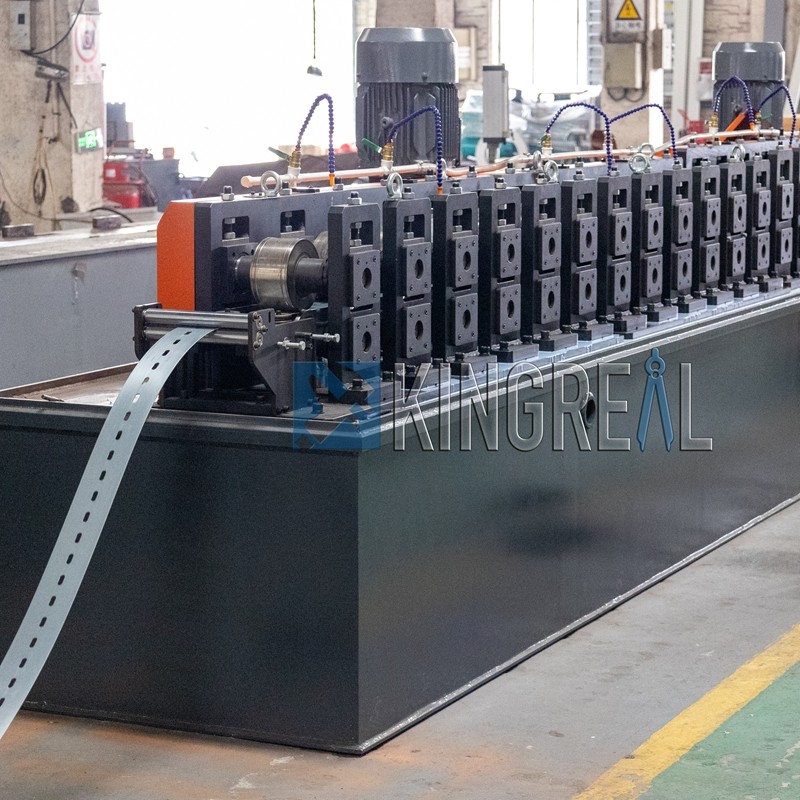

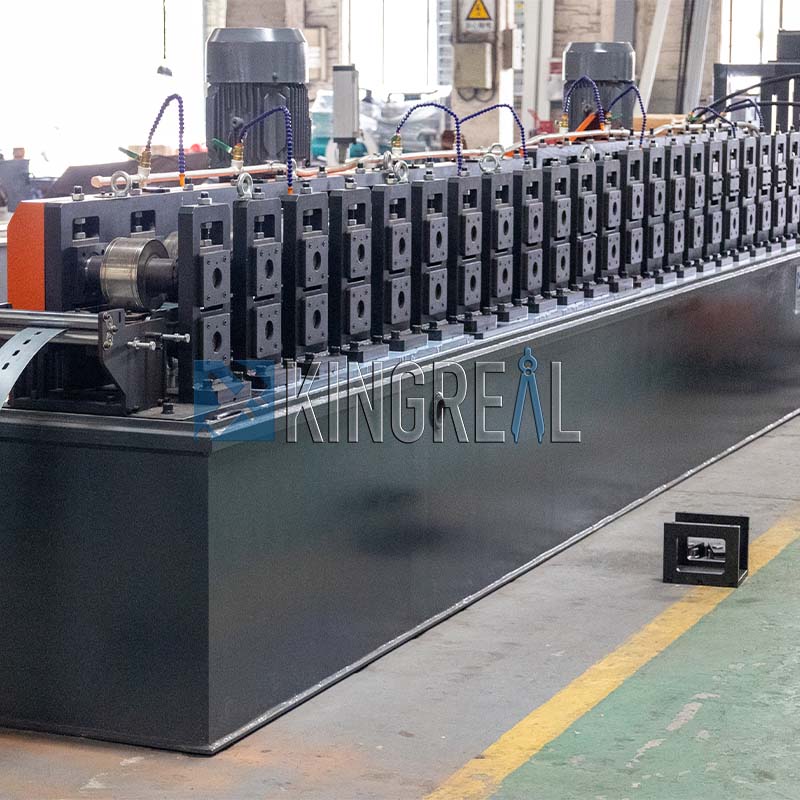

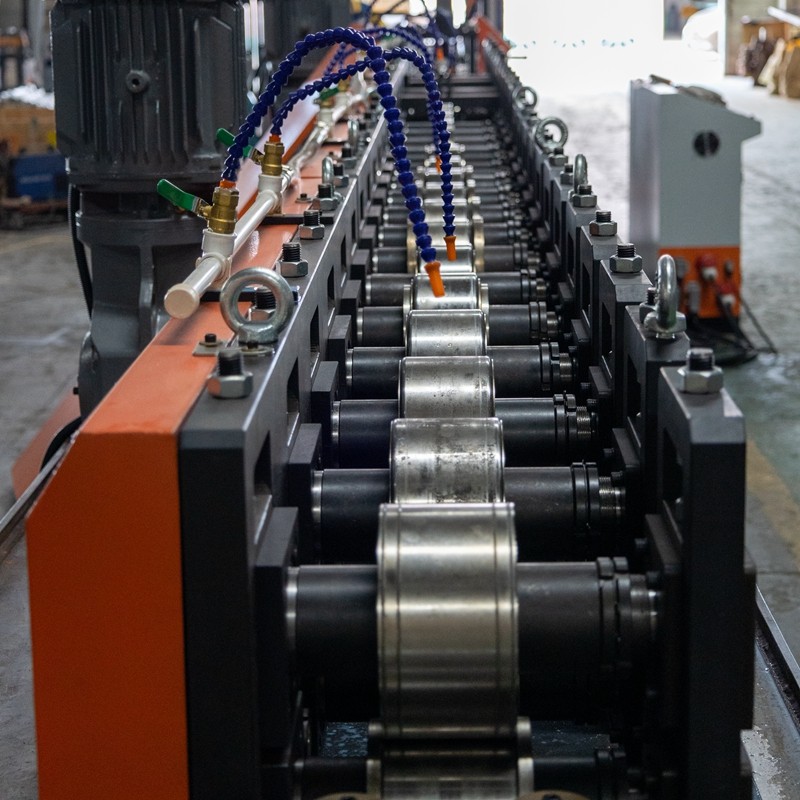

Main roll forming machine

The main roll forming machine is flexible in design. By manually adjusting or replacing different groups of rollers, it can easily complete the production of different specifications of brackets on a solar mounting strut channel production line. Its forming speed can reach up to 15 m/min, ensuring the efficiency and stability of the production process.

Cutting station

The KINGREAL solar mounting strut channel making machine is equipped with an advanced cutting station with a follow-up shearing function. During the cutting process, the equipment does not need to be shut down, which greatly reduces downtime and improves production efficiency. In addition, this design also effectively reduces the waste of metal materials and further reduces production costs.

Auto Packaging machine

In order to maximize the production speed of customers, KINGREAL has designed an automatic packaging machine for the solar mounting strut channel making machine. When the solar mounting strut channel is cut according to the customer's length requirements, it will be directly transported to the packaging machine for automatic packing and stacking. This process eliminates the tedious steps of manual handling, packing and stacking in the middle, which not only saves time costs for the factory, but also reduces labor costs and improves overall production efficiency.

Advantages Of Solar Mounting Strut Channel Production Line

1. One machine with multiple functions

KINGREAL solar mounting strut channel machine has the characteristics of one machine with multiple functions, and can produce photovoltaic brackets of various specifications. Whether the bracket size required by the customer is 41 × 21 mm, 41 × 41 mm or other sizes, it can be completed through simple settings and adjustments. This flexibility allows customers to quickly adjust production plans according to market demand, improving production flexibility and efficiency.

2. Adjustable forming speed

The speed of the main roll forming machine can be adjusted according to actual production needs, up to 15 m/min. This feature allows customers to flexibly adjust the production speed according to different order quantities and production conditions to achieve optimal production efficiency and resource utilization. Whether it is small batch production or large-scale production, KINGREAL solar mounting strut channel making machine can easily cope with it.

3. Customized service

KINGREAL is committed to providing customers with highly customized manufacturing solutions. Customers only need to provide design drawings and specific requirements, and KINGREAL engineers will communicate with customers to deeply understand the specific requirements of the project, including coil thickness, finished product size, etc. Based on this information, engineers will adjust the solar mounting strut channel production line's parameters and configuration according to the customer's actual situation to ensure the best adaptability of the equipment and help customers achieve efficient production.

Application Fields Of Solar Mounting Strut Channel

Photovoltaic brackets play a vital role in the construction of solar panel frames and mounting systems, and are widely used in residential and commercial buildings, solar power plants, agricultural applications, transportation infrastructure and other fields.

Globally, especially in countries such as the United States, Australia, Brazil, Germany, Japan and India, the demand for photovoltaic brackets is growing rapidly. Government policies, public awareness and industrial technological progress in these countries have jointly promoted the development of the photovoltaic market, providing a broad market space for photovoltaic bracket manufacturers.

Quality Inspection

KINGREAL solar mounting strut channel machine adopts advanced manufacturing technology to ensure the high precision of the finished product. The size of each bracket strictly meets the customer's requirements, and the deviation value is extremely low, which ensures the adaptability and effectiveness of the product in practical applications. This high-precision production capacity makes the photovoltaic bracket more stable during installation and improves the reliability of the overall system.

The finished product undergoes strict quality control before leaving the factory to ensure that the photovoltaic bracket produced is burr-free. This design not only improves the appearance quality of the product and avoids possible injuries to workers during the installation process, but also improves the matching accuracy between the bracket and the photovoltaic module, ensuring the stability and safety of the system.

Solar Mounting Strut Channel Production Line in Mexico

KINGREAL customized a manufacturing solution for the solar mounting strut channel making machine with auto packaging machine according to customer needs, and successfully manufactured and shipped it to the customer's factory in Mexico. KINGREAL's engineers traveled to the customer's factory to conduct solar mounting strut channel making machine installation and operation training. At present, this solar mounting strut channel production line has been successfully put into operation in the customer's factory. Customers reported that the equipment performed well during operation, worked smoothly, and greatly improved production efficiency.

(If you want to know more about this case, please click here → Mexico Project -- solar strut channel machine

Why Choose KINGREAL?

1. One-stop service

From the design stage, KINGREAL's team will work closely with customers to understand their specific needs and project requirements. Whether it is solar mounting strut channel production line parameter design, solar mounting strut channel making machine manufacturing, delivery arrangement, or after-sales installation and operation guidance, KINGREAL will be responsible for the whole process.

2. Professional team

KINGREAL has an experienced professional team, and the team members have deep machine knowledge and rich industry experience. During the operation of the solar mounting strut channel production line, customers may encounter various problems. KINGREAL's team can quickly provide effective solutions to ensure the smooth progress of the production process.

3. Quick response

KINGREAL has a 24-hour customer service team, providing online and offline support services. No matter when customers encounter problems, just contact KINGREAL at any time, KINGREAL's customer service team will respond quickly and solve customers' questions and needs in a timely manner.

4. Customized solutions

KINGREAL is committed to providing tailor-made solutions, and can adjust the design and parameters of the solar mounting strut channel making machine according to the specific needs of customers and project characteristics.

KINGREAL After-sales Services

KINGREAL has accumulated rich experience in after-sales service. KINGREAL is well aware of the importance of the smooth operation of the solar mounting strut channel production line to customers, so it has established a complete after-sales service system to ensure that customers can get timely and effective support during use.

In order to ensure that customers can give full play to the performance of the solar mounting strut channel making machine, KINGREAL provides professional offline installation services. KINGREAL's technical team will personally go to the customer's country to install and debug the solar mounting strut channel machine to ensure that the equipment operates in the best condition.