Unistrut U Channel Roll Forming Machine

KINGREAL is a professional Unistrut U Channel Roll Forming Machine manufacturer in China. With many years of production experience and technical experience, it can provide various specifications of high quality photovoltaic support forming machine products with stable performance and reliable precision.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

What is a photovoltaic support?

The Photovoltaic bracket or Sloar Post refers to the support frame used to install solar photovoltaic system. Photovoltaic brackets are usually made of steel or aluminum alloy, which can be produced by

unistrut u channel machines, and adopt different structures, which can be applied to different installation environments.

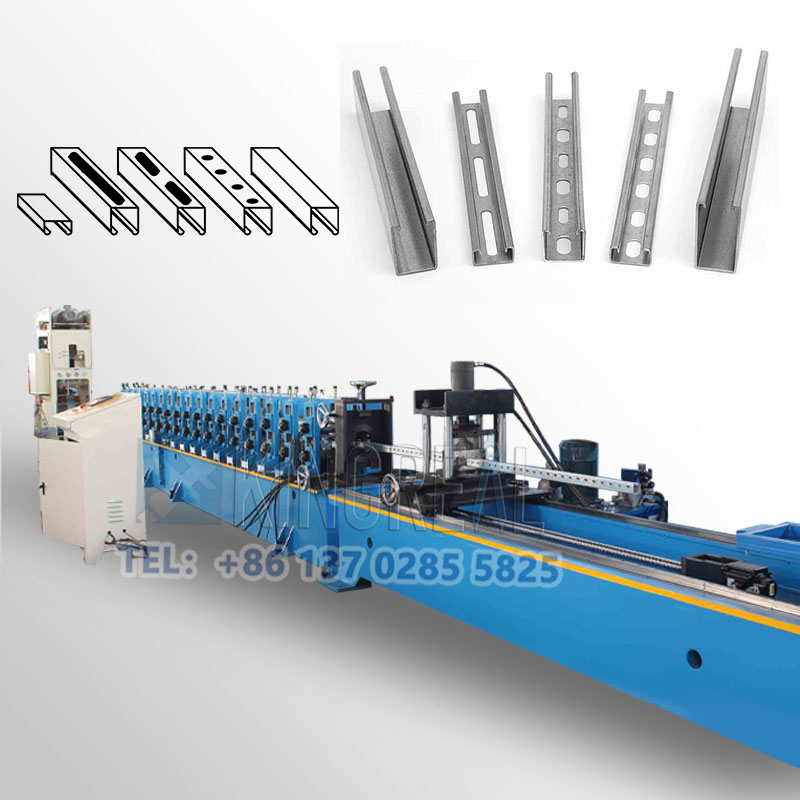

Slotted C Unistrut Channel Forming Machine Description

The photovoltaic support is mainly manufactured by a special Slotted C Unistrut Channel Roll Forming Machine, which is a kind of mechanical equipment specially used to make solar photovoltaic supports.

It is mainly used to make photovoltaic brackets such as angle steel brackets and pipe brackets. It can shape steel plates with a thickness of 1.5mm-3.0mm through stamping, bending, cutting and other processes, making it a solar photovoltaic support that meets the installation requirements.

KINGREAL slotted c channel roll forming machine can produce different post, including 41×21, 41×41, 41×62, 41×82 and other specifications.

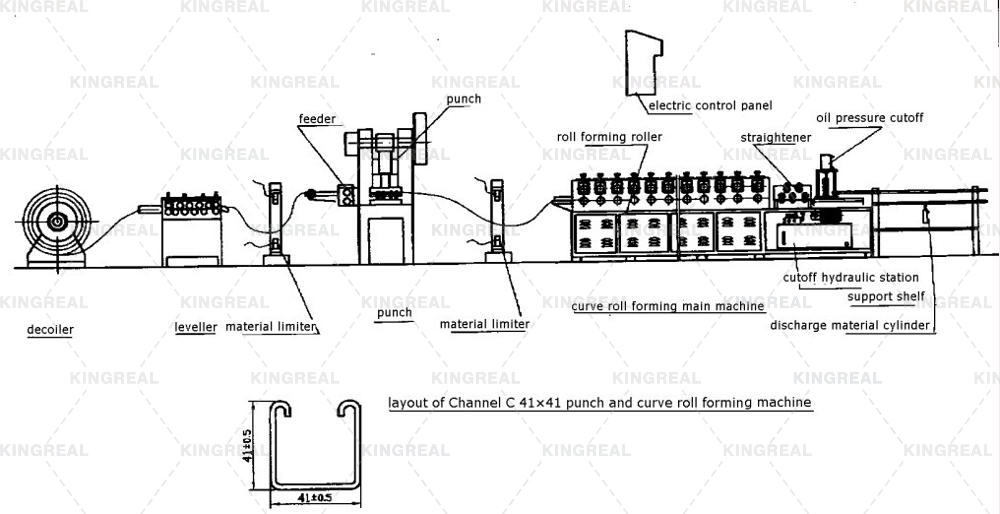

Working process of Slotted C Channel Roll Forming Machine

Decoiler -- Straightener -- Feeder Roll -- Punching Machine -- Roll Forming Machine -- Cutting Machine

(The above production process is for reference only, the actual machine needs to be designed according to the needs of customers)

Specification Of Metal Slotted C Channel Machine

| Material | Galvanized Steel |

Thickness | 1.5mm |

Cutting Material | CR12 Mould Steel |

Working Speed | 10-15M/Min |

Hydraulic Station | Motor 15.5KW |

Main Components Detail Of Slotted C Channel Machine

1. 110 TONS High Speed Punch Press KINGREAL use 110 tons high speed press to punch the hole. And the machine including one set of punch mold. The press is famous brand YANGLI, China. Perforation Moulds The perforation mould is high quality wire cut molds, the core materials is Cr12MoV which is featured with endurable and long-life time. |  |

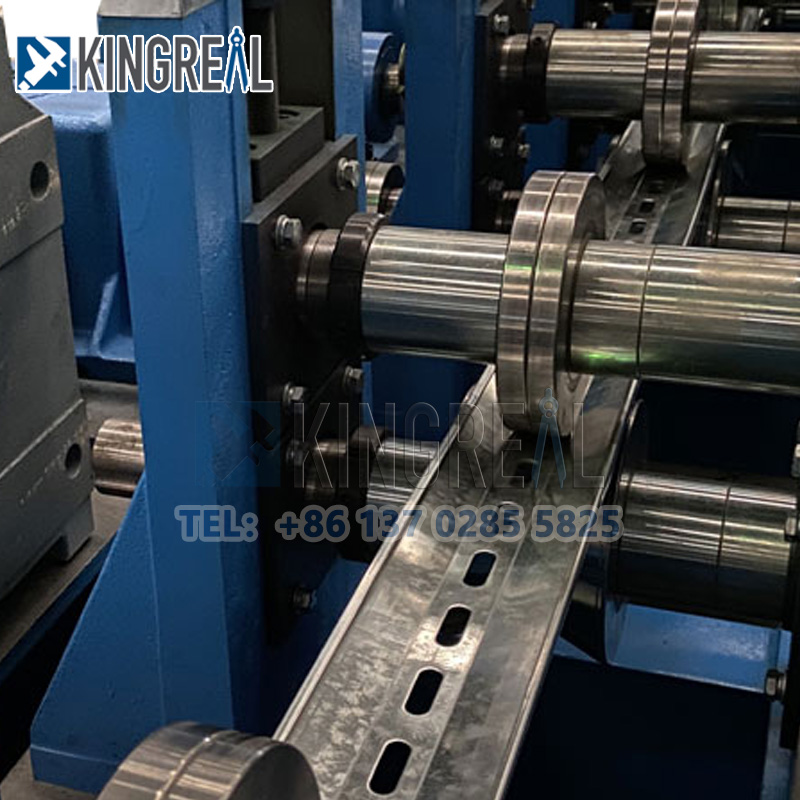

2. Main Roll Forming Machine The main roll forming machine is for auto forming the perforated materials to the required shapes. The machine frame is welded by steel panel to one piece structure. Then one whole piece panel will be put on the frame after fine processed by the planomiller. This will ensure the accuracy basic size. Also it will increase the machine strength to reduce the deformation influence. |  |

3. Hydraulic Shearing Part a. The hydraulic parts use high efficiency environmental protection energy storage type hydraulic system. And it adopts Taiwan hydraulic components and equipped with air cooling system. b. Shearing Method: hole insert cut, the blade material is D2 with quenching treatment hardness up to HRC60℃. |  |

Quality Inspection

KINGREAL's unistrut u channel machines are highly valued by customers for their superior performance and reliable quality. When taking customers on a factory tour, KINGREAL arranges to see the actual operation of the strut channel machine up close and invites customers to inspect the unistrut channel in person. This process not only demonstrates the efficient production capabilities of KINGREAL unistrut channel machines, but also enhances the customer's trust in product quality.

Customers have observed on site that KINGREAL machines produce unistrut channels in full compliance with preset parameters, demonstrating excellent accuracy and consistency. They were amazed that the strut channel had a smooth surface without scratches and a flat cutting surface, reflecting advanced manufacturing processes and strict quality control.

Application

Photovoltaic brackets are support frames used to install solar photovoltaic systems, designed to ensure the stability and effectiveness of photovoltaic modules. Photovoltaic brackets can be divided into ground photovoltaic brackets and roof photovoltaic brackets. With the global emphasis on renewable energy, the demand for photovoltaic brackets is growing, and they are now widely used in many countries. Among them, there is particularly strong demand in the United States, Germany, Australia, India, Japan and other countries. Driven by policy support, market demand and technological progress, these countries have promoted the widespread application of photovoltaic brackets and helped the development of global renewable energy.

Different Types of Struct Channel Producted in One Machine

In order to maximize the production efficiency of KINGREAL customers and meet the demand for finished products of different specifications, KINGREAL has innovatively designed a multi-functional unistrut channel machine that can flexibly produce different types and sizes of PV brackets. The machine is designed to quickly adapt to production requirements of different specifications by simply manually adjusting or changing several sets of rolls. This flexibility not only improves the utilization of the production line, but also significantly reduces the time to production conversion.

The speed of roll replacement is very fast, making the production process more efficient, and the customer can quickly adjust the production plan according to the market demand, avoiding the loss of production due to the mismatch of specifications. In addition, this design also saves the high cost of buying multiple special solar mounting strut channel machines, reduces equipment investment and maintenance costs, and greatly improves the economic benefits of enterprises.

This innovative solution from KINGREAL gives customers the flexibility to stay ahead of the competition in the face of changing market demands. Through this efficient production method, customers can not only improve production efficiency, but also ensure product quality and meet the market demand for diverse and high-quality photovoltaic brackets.

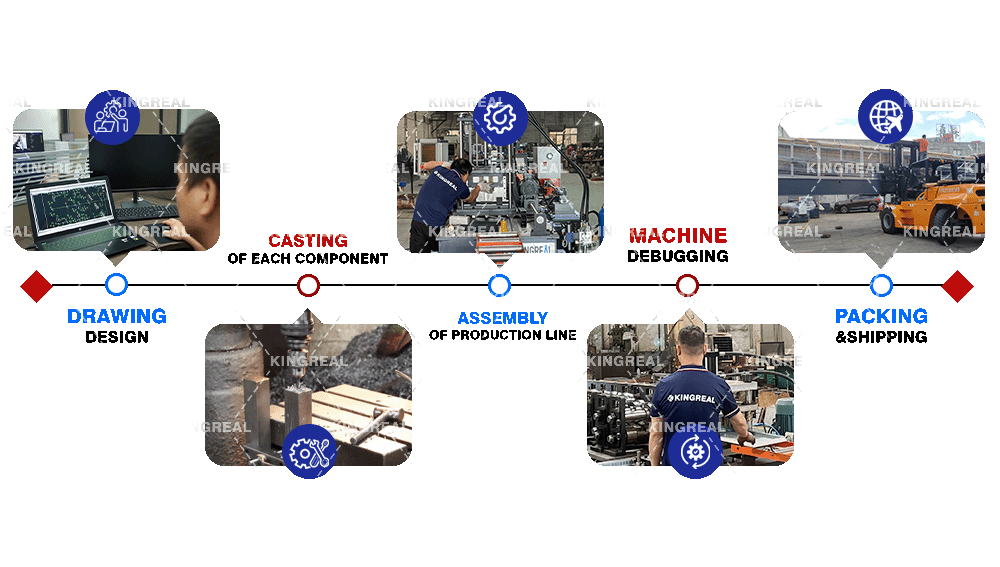

KINGREAL Technical Team

KINGREAL has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of Light Steel Keel Roll Forming Machine, from design - production - installation - after-sales, our team has an excellent standard.