Wall Panel Cladding Machine

KINGREAL wall panel cladding machine produce different kinds of wall panels, it's widely praised for high speed, flexible size change and high accuracy.

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video About Wall Cladding Panel Machine

Definition Of Wall Cladding Panel Machine

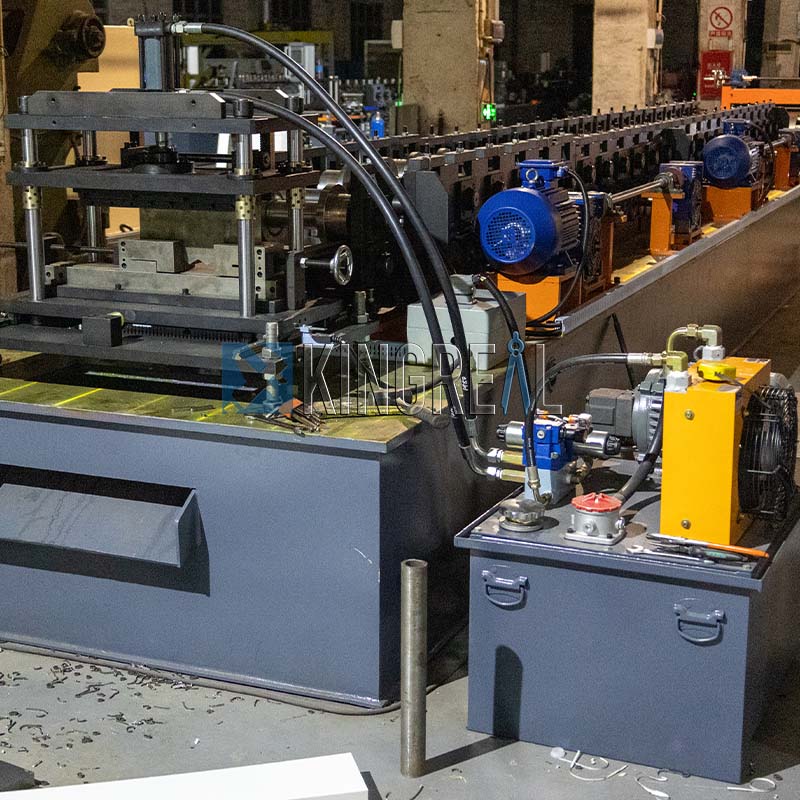

The wall panel cladding machine is one of KINGREAL's featured machines. Through a series of efficient work processes such as unwinding, forming, and cutting, it can produce wall panels quickly and accurately. Its fully automated design not only improves production efficiency, but also ensures product consistency and quality. In addition, this wall cladding panel production line has the function of flexible size adjustment to meet the special needs of different customers and projects.

As a modern building material, wall cladding panels are popular because of their multiple advantages. It is not only easy to install and reduces construction time, but also has excellent durability and economy, which can effectively reduce building maintenance costs. These characteristics make wall panels an ideal choice to meet the market's demand for high-quality building materials and are widely used in residential, commercial and industrial construction projects.

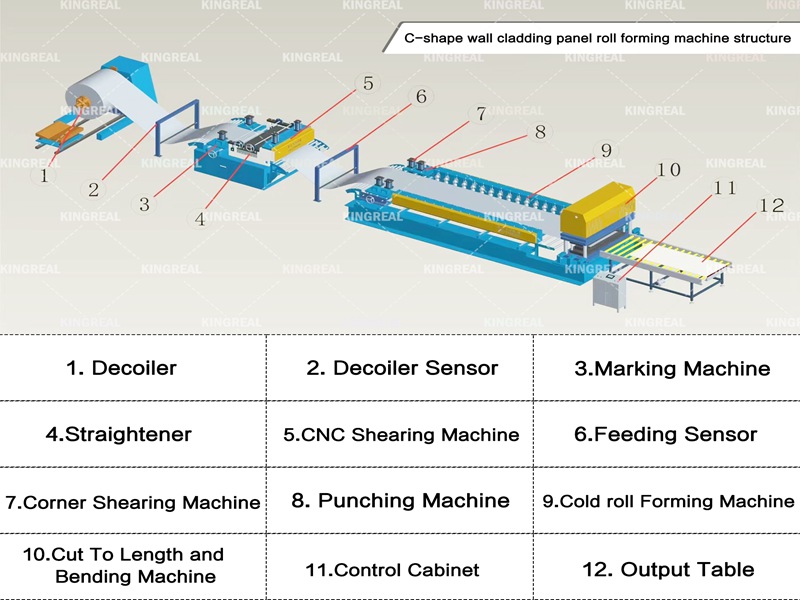

Working Process Of Wall Cladding Panel Production Line

Decoiler -- Decoiler Sensor -- Marking Machine -- Straightener -- CNC Shearing Machine -- Feeding Sensor --Corner Shearing Machine -- Punching Machine -- Cold Roll Forming Machine -- Cut To Length and Bending Machine -- Control Cabinet --Output Table

Features Of Wall Cladding Panel Machine

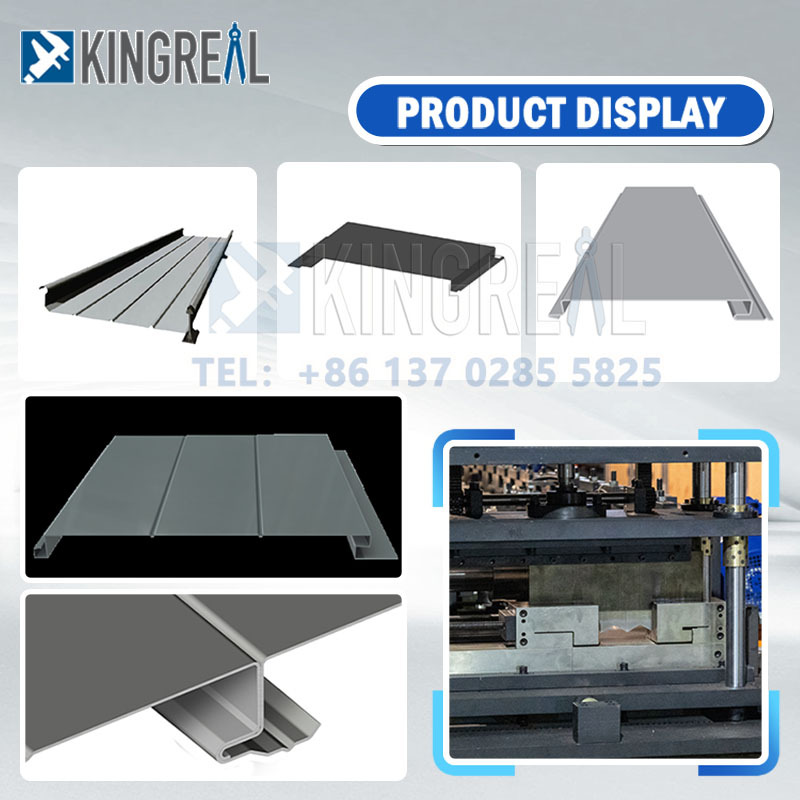

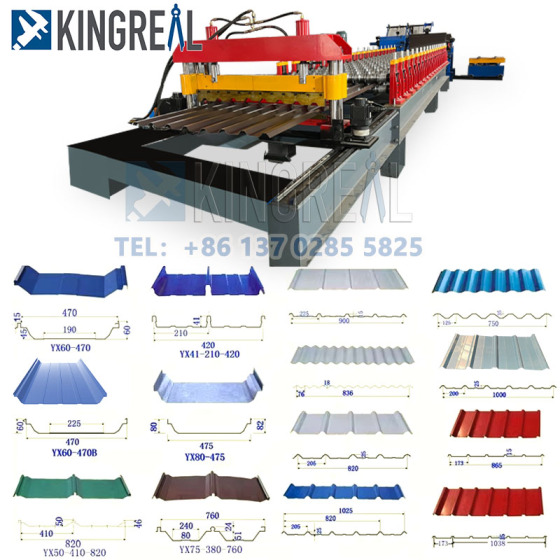

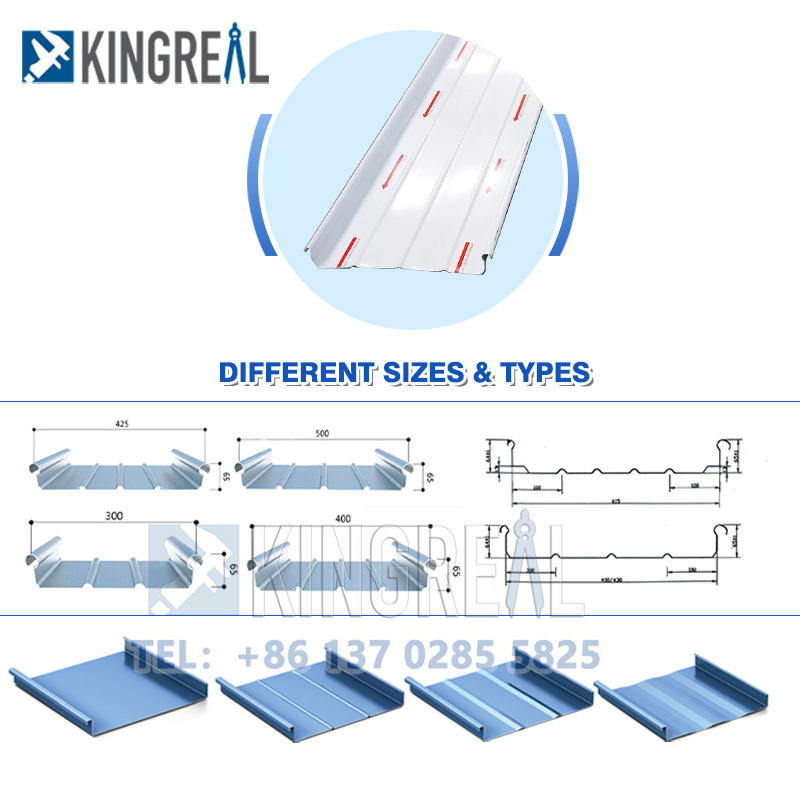

Diverse wall cladding panel manufacturing solutions

KINGREAL engineers will design customized wall cladding panel machine solutions based on the specific needs of customers to ensure that different market needs are met. Whether it is a common wall panel such as a flat panel, v-rib, pencil rib or clip relief, KINGREAL has corresponding wall cladding panel production lines to choose from to help customers achieve efficient production.

In addition to standard designs, KINGREAL also offers innovative options that use the latest technologies and materials to improve efficiency and product quality. KINGREAL customized solutions not only simplify the manufacturing process, but also optimize resource utilization, helping KINGREAL customers reduce waste and increase profitability.

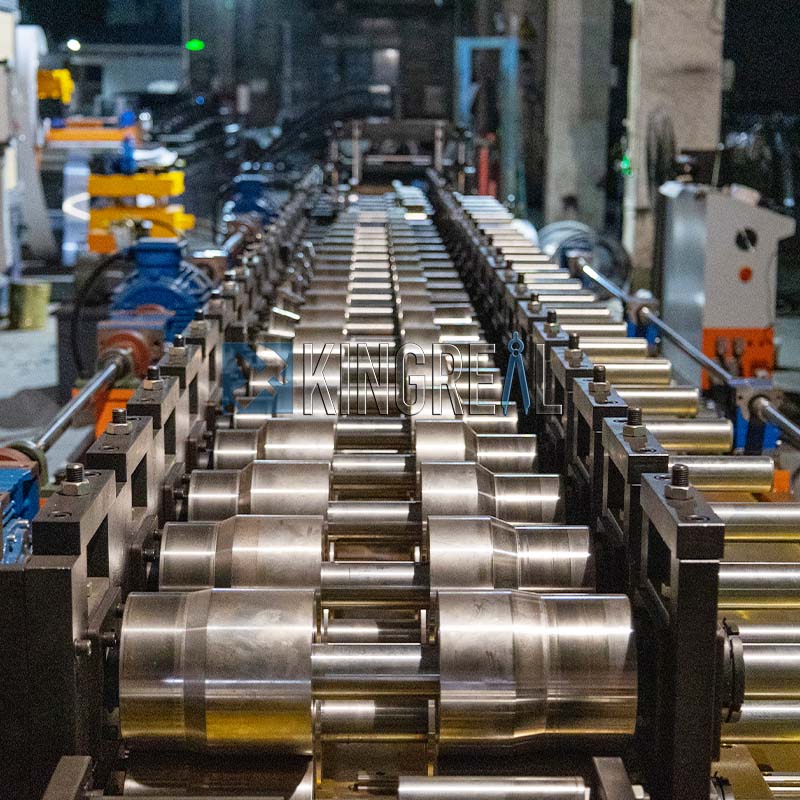

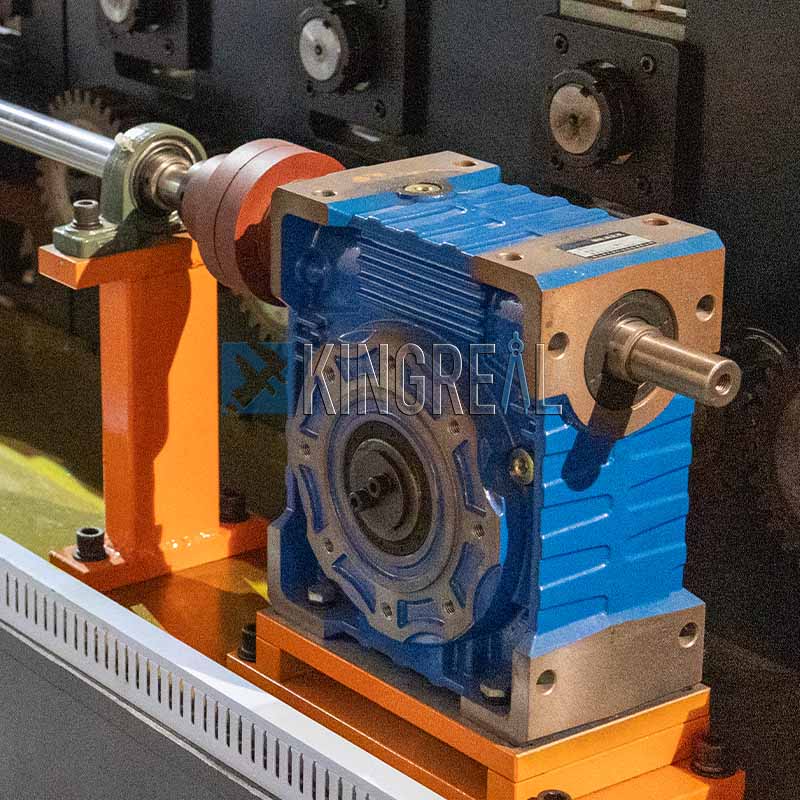

High-precision

KINGREAL's wall cladding panel machine is equipped with advanced roll forming machines and precision components such as cutting machines to ensure high precision of the wall cladding panels. High-quality mechanical components produce burr-free surfaces, and under the same parameters, the wall panels produced have extremely strong consistency.

Fully automated operation

KINGREAL's wall cladding panel production line integrates a fully automated design to make the production process more efficient. Users only need to simply set the relevant parameters, and the machine can operate fully automatically, significantly reducing the need for manual intervention. This not only improves production efficiency, but also reduces the possibility of human errors and ensures the stability of the production process.

Flexible size adjustment

KINGREAL's wall cladding panel machine has flexible functions, which can easily adjust the height and width of the wall panel according to needs. This means that users only need one wall panel cladding machine to produce finished products of various specifications, which greatly improves the flexibility and adaptability of production and helps customers respond quickly to market changes.

Smooth Operation

KINGREAL's wall cladding panel machine operates at a production speed of 15 m/min, ensuring a steady and efficient workflow throughout the entire manufacturing process. This smooth operation minimizes vibrations and disruptions, allowing for consistent production of wall cladding panels that meet customer specifications. The reliable performance not only enhances overall productivity but also ensures that the quality of the wall panels remains high, fulfilling the diverse needs of clients in various industries.

Customer Feedback on KINGREAL Wall Cladding Panel Machine

Excellent production efficiency

Customers generally report that KINGREAL's wall cladding panel machine has significantly improved production efficiency. Thanks to its fully automated design and high-precision mechanical components, this wall panel cladding machine can quickly complete the forming and cutting of wall panels, shorten the production cycle, and help customers seize the initiative in the fierce market competition.

Excellent space and cost-effectiveness

Compared with traditional wall cladding panel production lines, KINGREAL's wall panel cladding machine shows obvious advantages in space utilization and cost control. Its compact design effectively reduces the occupied production space and makes the layout of the factory more reasonable. At the same time, the high efficiency and low energy consumption of the wall cladding panel production line not only reduce operating costs, but also improve the overall economic benefits, bringing greater protection for customers' return on investment.

Precision Cutting

Customers appreciate the precise length cutting feature of KINGREAL's wall cladding panel machine. With just a few settings on the control panel, the wall cladding panel production line can efficiently uncoil, form, cut, and discharge the metal raw materials according to specified instructions. The wall cladding panel production line ensures that the wall panels are exceptionally accurate, consistently matching the dimensions set in the parameters. This level of precision not only enhances product quality but also minimizes material waste, making it a valuable asset for any production facility.

Application Areas Of Wall Panels

As a modern building material, wall cladding panels are widely used in airports, railway stations, offices, hotels and other high-end places due to their superior performance and beautiful appearance. Through their wide application in these places, wall cladding panels not only enhance the overall value of the building, but also provide users with a more comfortable and safe experience.

Why Choose KINGREAL?

High-quality machines

KINGREAL is always committed to providing customers with high-quality machines. KINGREAL adopts strict standards in the selection of raw materials to ensure that only high-quality materials are used. Every link in the manufacturing process follows a rigorous workflow, from design to assembly, to the final test machine, each step is carefully controlled by a professional team. Through comprehensive quality inspections, KINGREAL ensures that each machine meets the highest standards of the industry before delivery, bringing customers a reliable use experience.

Professional team

KINGREAL has more than 20 years of experience in machine manufacturing and has built a highly qualified professional team to provide answers and support to customers at any time. Whether it is a problem encountered during the use of the machine or a consultation on selection and maintenance, KINGREAL's team can respond quickly and give professional advice. KINGREAL understands that customers' time is valuable, so it provides flexible communication methods and can arrange telephone and video conferences according to the time of the customer's region to ensure timely delivery of information and rapid resolution of problems.