CU Channel Roll Forming Machine

KINGREAL CU Channel Roll Forming Machineis featured with some most advanced technology, which makes it reach an unbelievable production speed (up to 120m/min).

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

CU Channel Roll Forming Machine Description

KINGREAL High Speed Studs And Tracks Making Machine can produce various sizes of studs, tracks on one machine. Based on different customer‘s request, there are different ways to adjust the width, automatically or manually. The studs and tracks roll forming machine is used for production of different sizes of studs and runners, the output speed is up to 120m/min,featured with follow punch and fly shearing system.

KINGREAL have several cutting methods for this machine such as fixed station cutting, follow shearing and fly shearing. Also, the cutting molds can be customized to produce different shapes of products.

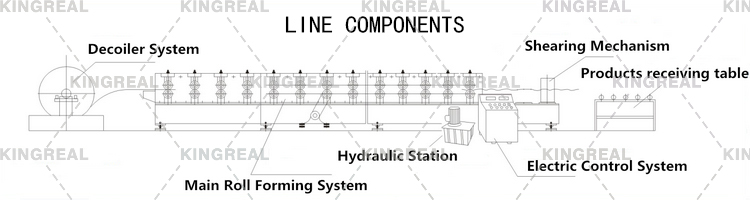

Working Process Of CU Channel Roll Forming Machine

Double heads decoiler -High speed cold roll forming -Combi structure for your choice to produce different steel profiles on one machine -Machine protection -Hydraulic fly shearing -Auto stacking system for your choice.

Main Components Details

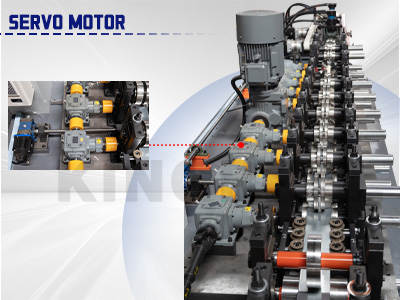

Roll Forming Machine 1. The machine frame is a single-piece structure that is welded together using steel panels. Following fine processing by the planomiller, one panel with a thickness of 20 mm will be installed on the frame. This will guarantee the fundamental size accuracy. Moreover, it will strengthen the machine to lessen the impact of deformation. 2. Archway panel: separate construction and method of surface blackening. 3. Driving System: Gear driving rollers construction with liner drive provided by main drive motor and reducer motor. The main axle has a diameter of 60 mm, is made of 40Cr material, and is finely ground following a heat treatment known as quenching. |  |

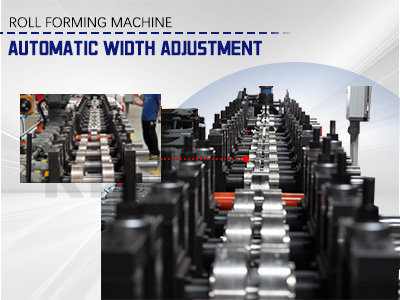

Automatic Width Adjustment Design a. Fast change the products width: it adopts electrical method to change the products width. Yaskawa Servo motor will be equipped for the auto width change. |  |

Hydraulic Punch & Shearing b. Fly Shearing System Fly Punching The system consists of a fly shearing and fly punch system. Set the output speed to high. |  |

Drywall Profiles Auto Package Machine

KINGREAL specializes in an automatic production line for the 2-6m drywall profiles, aluminum tube and other building materials industry, with a lot of labor, low obedience, and research and development. The work process of automatic buckle, automatic rectification, automatic arm palletizing and automatic plastic steel bundling is adopted to form an automatic/efficient/stable automatic palletizing and packing line.

This production line adopts PLC control and has a high degree of automation. And it has the advantages of saving manpower, reducing labor intensity, reducing costs, and reducing injuries to employees, and is more suitable for industry competition.

Quality Control

KINGREAL's CU channel roll forming machine uses high-quality materials to manufacture each component, which not only improves the overall quality of the machine but also ensures its excellent performance. Thanks to these high-quality materials, KINGREAL's CU channel making machines are able to produce high-precision finished products that fully meet the production needs of customers.

In addition, KINGREAL focuses on the rigor of the process and the standardization of the process, so that each CU channel making machine can maintain a high degree of consistency during the production process. This consistency not only improves production efficiency, but also reduces the scrap rate, thereby creating greater economic value for customers.

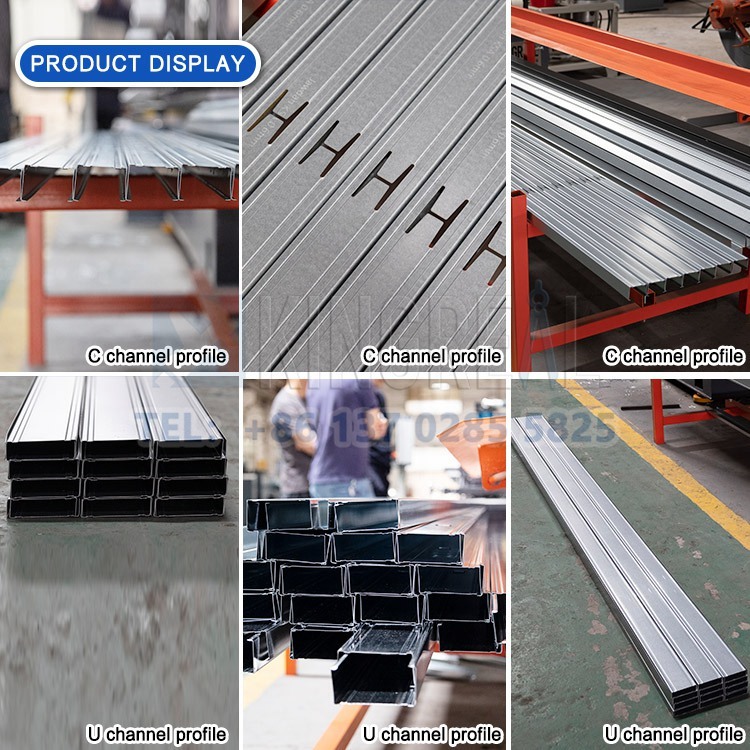

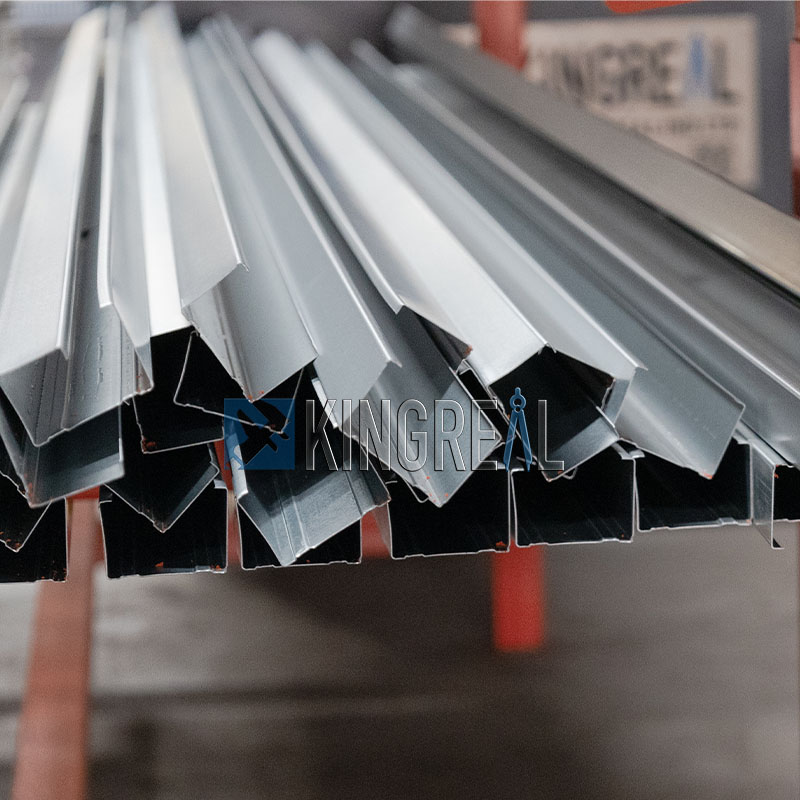

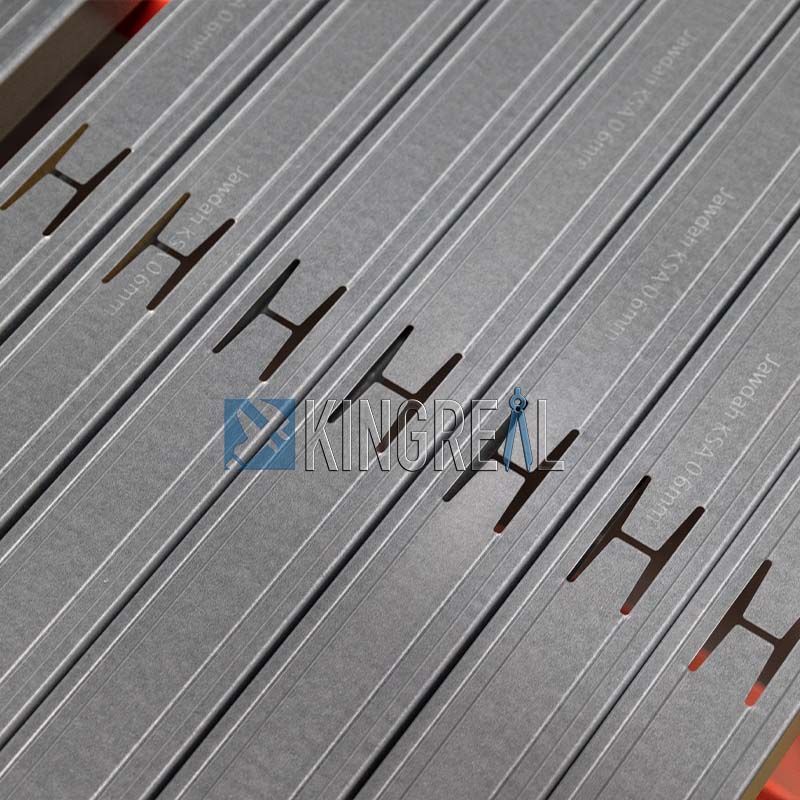

Product Display

KINGREAL's CU channel making machine can efficiently produce CU channels of various sizes, which are carefully designed for partition wall construction projects to ensure that they can effectively support the wall structure and provide excellent stability and load-bearing capacity.

CU channels are made of high-strength materials and have excellent corrosion resistance, which makes them perform well in wet or harsh environments and prolongs their service life. In addition, its lightweight design makes transportation and installation more convenient, greatly reducing construction time and labor costs. It is widely recognized and in demand in the market and has become an indispensable and important material in modern construction projects.

KINGREAL Rich Experience About CU Channel Machine

KINGREAL has a professional technical team with more than 25 years of relevant experience from the drawing design to the manufacturing of Stud and Track Machine, from design - production - installation - after-sales, KINGREAL has an excellent standard. KINGREAL has established the localized technical support team in Canada, India, Saudi Arabia, Turkey, Chile and etc.. Localized service points in other countries are also in progress.

FAQ

1. Are you a manufacturer?

Yes, KINGREAL Machinery is a professional sheet metal processing machines manufacturer, we are an OEM.

KINGREAL have been focusing on the field of machine manufacturing for more than 20 years.

2. How to visit your factory?

There are 2 ways: either by plane or by train to Foshan/Guangzhou port. KINGREAL will be picking you up in plane/train station, then we can go together.

3. What's your delivery Time ?

Within 60-80 days after receiving prepayment. Some machines in stock, can be delivered at any time.

4. What's your payment terms ?

40% deposit is paid before production, the balance paid after inspection confirmation before shipment.

5. What's your Install and Training ?

If buyers come to KINGREAL factory to inspect, the training to install and operate is provided face to face.

If not, Manual book and video is provided to show how to install and operate.