Drywall Stud And Track Roll Forming Machine

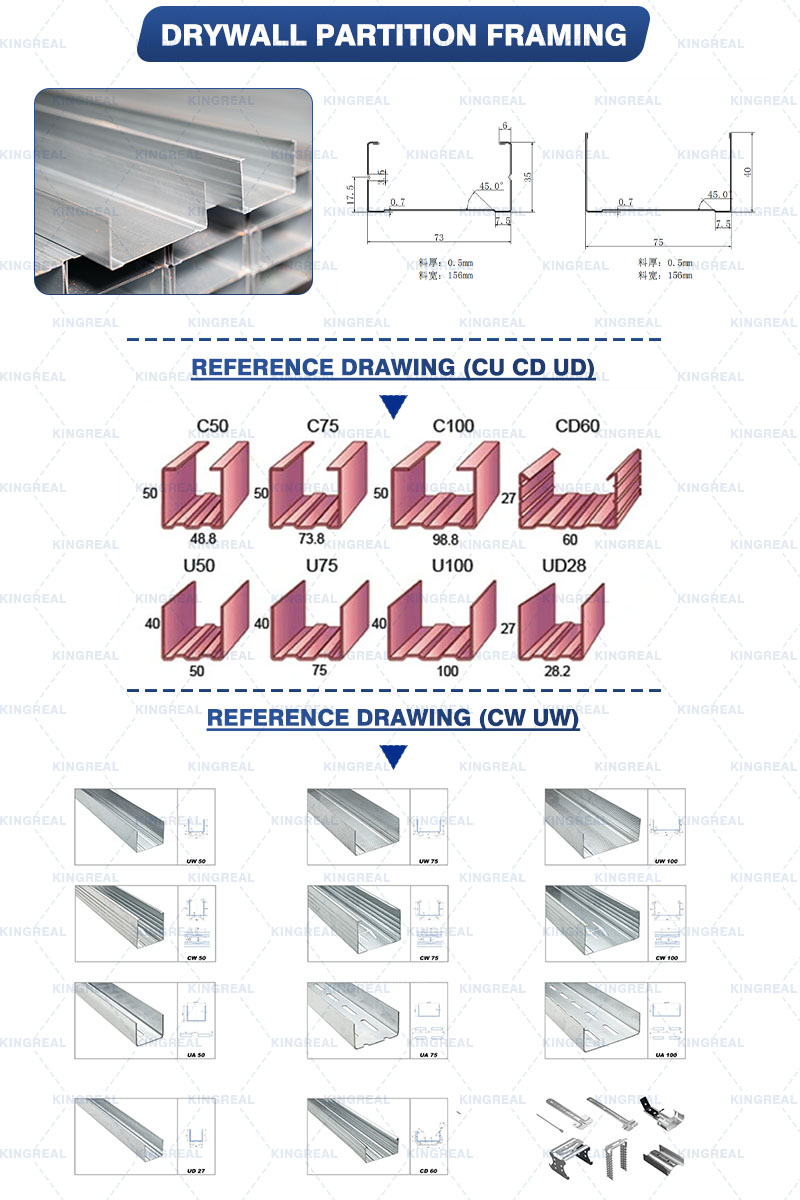

Stud and Track Roll forming Machine used for manufacturing steel framing components. One of the most common building and construction materials is the steel stud and track. The stud and track roll forming machine that is used to form these steel studs and track is the “Stud and Track Roll Forming Machine".

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video About Stud And Track Roll Forming Machine

Drywall Stud And Track Roll Forming Machine Description

Stud and Track Roll forming Machine used for manufacturing steel framing components. One of the most common building and construction materials is the steel stud and track. The stud and track roll forming machine that is used to form these steel studs and track is the “Stud and Track Roll Forming Machine“.

The common configuration includes advanced features such as automatic material thickness (gauge) control and material handling systems. Production speed as much as 120m/min the fabrication of studs and tracks must roll out without failure. The rollfromer is an integral part of the success of any stud supplier and is often the heart of the operation.

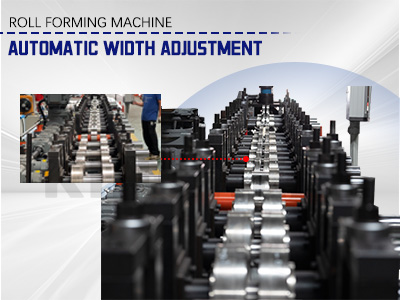

*AUTO WIDTH AND FLANGE HEIGHT ADJUSTBALE*

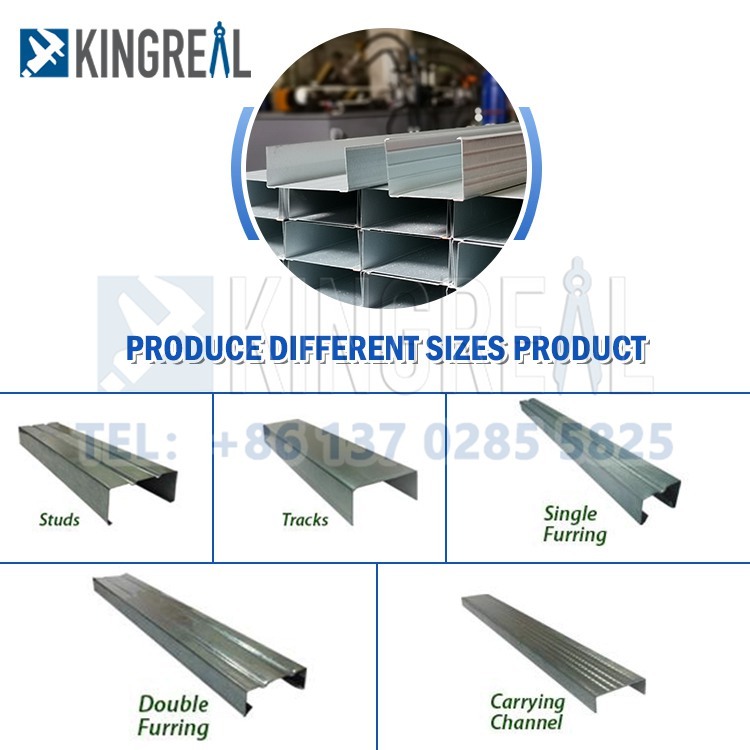

*ONE MACHINE FOR VARIOUS SIZES STUDS AND TRACKS PRODUCTION*

*HIGH SPEED FLY PUNCHING & SHEARING*

*120MMIN HIGH SPEED ROLL FORMING*

Technical Structure for Stud and Track Roll Forming Machines

The most common installation for stud and track roll forming machines include a number of auxiliary equipment. This equipment aids in the forming of the sheet metal into the correct studs and channels. The equipment required in rollform studs includes;

| 1. Uncoiler 2. Flatenner 3. Sheet Metal Lubricator 4. Pre-cut Dies 5. Pre-notching Press 6. Rolling Mill 7. Roll Tolling Stands 8. Post Cut Press 9. Flying Cut-off |  |

| Raw Material | GI Strip |

| Coil Thickness | 0.3-1MM |

| Woking Speed | About 40-120M/Min |

| Roll Forming Main Motor Power | 18.5KW |

| Hydraulic Station Motor Power | 11KW |

| Width Adjustable Servo Motor | 1.8KW |

| Power Supply | AC415V, 50HZ |

| Total Power | 40KW |

Stud And Track Machine Feature

| Raw Material Decoiler a. Power: no power, passive type b. Max. Loading Capacity: 1.5ton c. Material Inner diameter: φ480mm-φ520mm d. Max material external Diameter: <φ1200mm |  |

| Main Roll Forming Machine a. Machine frame: the machine frame is fused together into a single piece structure using steel panels. Following fine processing by the planomiller, one panel with a thickness of 20 mm will be installed on the frame. This will guarantee the fundamental size accuracy. Moreover, it will strengthen the machine to lessen the impact of deformation. b. Archway panel: separate construction and blackening procedure for surface. |  |

| Fly Punching & Fly Shearing A high-efficiency hydraulic system with energy storage and environmental protection is used in the hydraulic parts. Additionally, it has an air conditioning system and uses hydraulic components made by Taiwanese brands. b. Fly Shearing System Fly Punching The system consists of a fly shearing and fly punch system. Set the output speed to high. For the fast production, there will be two fly punching stations. |  |

FAQ

In order to allow the stud and track machine to run smoothly in high-temperature areas, does KINGREAL have corresponding measures?

In order to adapt to the environment of high-temperature countries in the Middle East such as Saudi Arabia, KINGREAL has equipped the metal stud and track machine with an additional cooling system. This measure can effectively protect the motor and ensure the stable operation of the equipment under high temperature conditions, thereby ensuring the smooth production of customers.

How to prove the quality of KINGREAL steel stud and track machine?

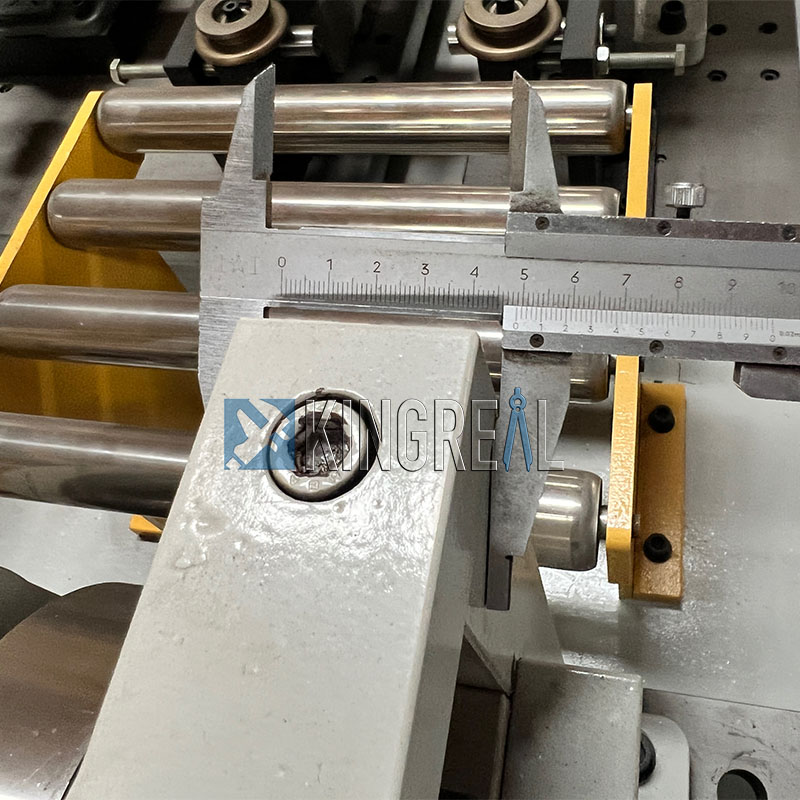

KINGREAL strictly controls the quality during the manufacturing process of the steel stud and track machine, and the selection of raw materials follows a series of high standards. In addition, the roller of the roll forming machine is made of durable Cr12Mov material, and the electrical components are selected from well-known brands to ensure the long-term stability and reliability of the equipment.

Can KINGREAL's metal stud and track machine produce finished products with its own brand logo?

Of course. KINGREAL can equip the customer's stud and track machine with a printer to directly print the customer's required logo during the production process of metal coils. This design is not only convenient, but also saves the subsequent additional printing process, making production more efficient.

Option Accessories Of Stud And Track Machine

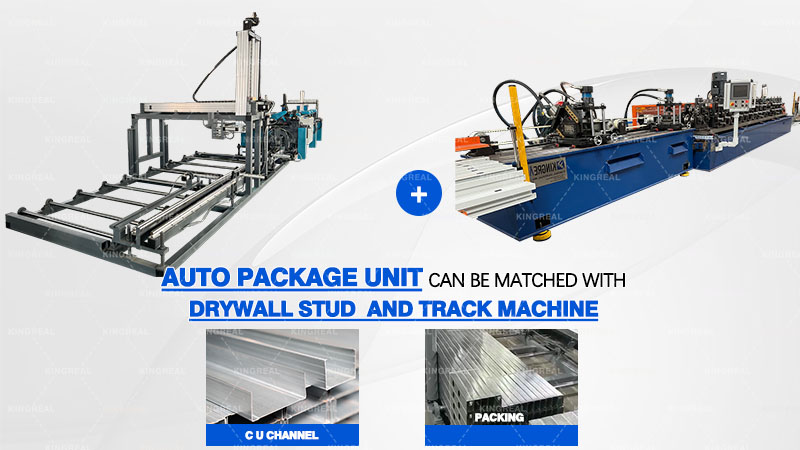

Many installations operate at very high speeds. For stud and track roll forming it’s common to reach line speeds of 500fpm or more. For the overall operation to be successful manufacturers must keep in mind the post production requirements.

As the forming machine discharges the stud at a high speed material handling equipment is required to stack and package the steel sticks in to bundles. Automated conveyor systems such as the following are typically required.

Software Control System

Integrating the rollforming machine in to your material handling software is critical to minimizing material waste. These two systems can ‘speak’ to each other in such a way that loading of specific coils and steel material types are selected. Having automated features within the roll former such as, auto web width, auto material thickness and auto flange height greatly increase the build to order process. With pulse generators and photo eye alignment sensors throughout the rolling mill PLC programs constantly monitor the high speed operation of the line.

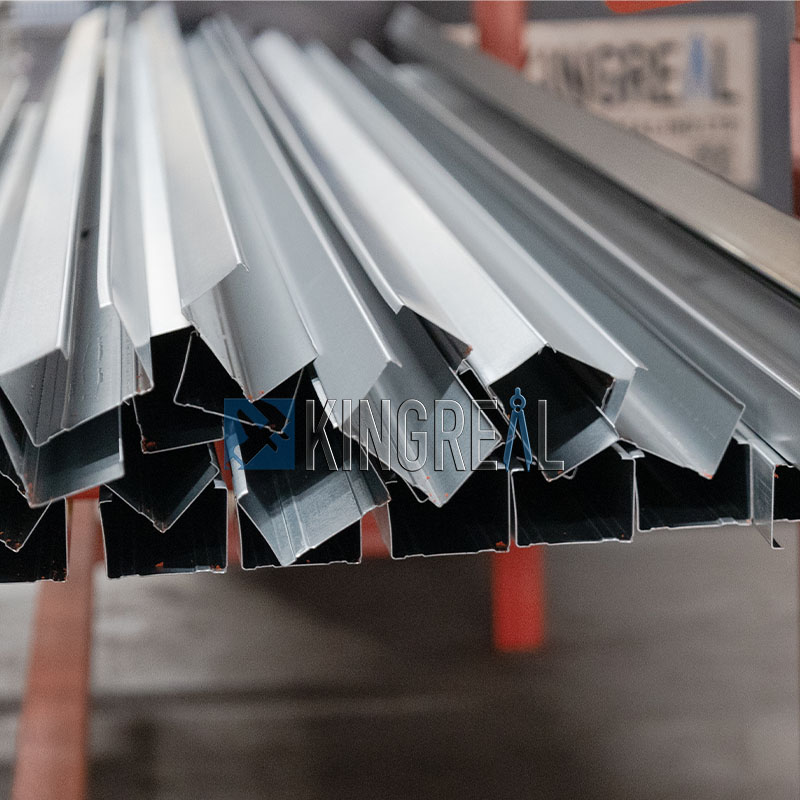

Product Display

KINGREAL metal stud and track machine is composed of multiple high-precision precision parts, ensuring that the stud and tracks produced have excellent precision and excellent surface quality, and are completely scratch-free. Under the same parameter settings, the finished products are highly consistent in size and shape, greatly improving the reliability and stability of the products.

After the stud and track machine is manufactured, KINGREAL's professional technical team will conduct strict testing and debugging of the equipment to ensure that the machine can achieve the best working condition. At the same time, the staff will conduct detailed measurements and inspections on each batch of stud and tracks produced to ensure that they fully meet the customer's high standards and high quality requirements for stud and tracks.

Benefits of Steel Framing for Drywall

Industrial building and construction projects rely on drywall steel stud systems. The quick installation and light weight characteristics of steel framing makes this an ideal product. Many job site forming machines lack the ability to produce stud and track to the right tolerances.

The installation of drywall requires the use of the correct drywall tools. These tools are engineered to match standard stud sizes used in commercial building. The drywall machine, or rollformer, must continuously produce the same sizes regardless of the steel coil used.

Successful Project

Steel stud and track machine is one of KINGREAL's featured machines. With its excellent performance and reliable quality, it has been successfully sold to many countries, including Canada, Chile, India, Russia, Saudi Arabia, UAE and Turkey. In these countries, KINGREAL's stud and track ceiling machine has many successful installation cases.

KINGREAL's engineering team has accumulated rich experience and in-depth understanding of the different parameter requirements of stud and track machines in various countries. This expertise enables KINGREAL to provide customers with tailor-made solutions to ensure that the products meet the standards and needs of the local market.

KINGREAL's customers highly value the professionalism and responsiveness of KINGREAL's staff. They believe that KINGREAL's metal stud and track machine is not only of excellent quality and fast production speed, but also has a very high return on investment.

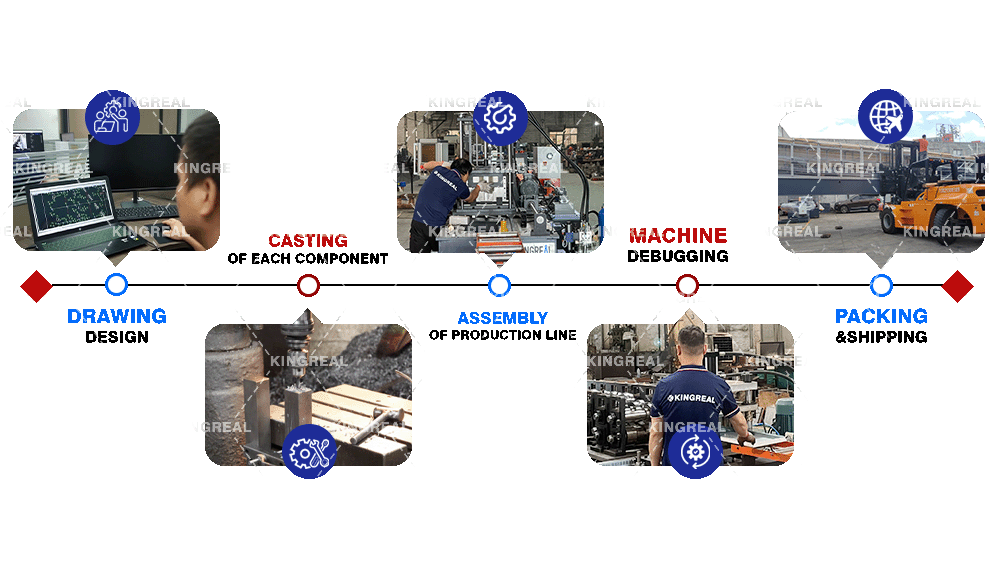

How To Manufacturing The Stud And Track Machine?