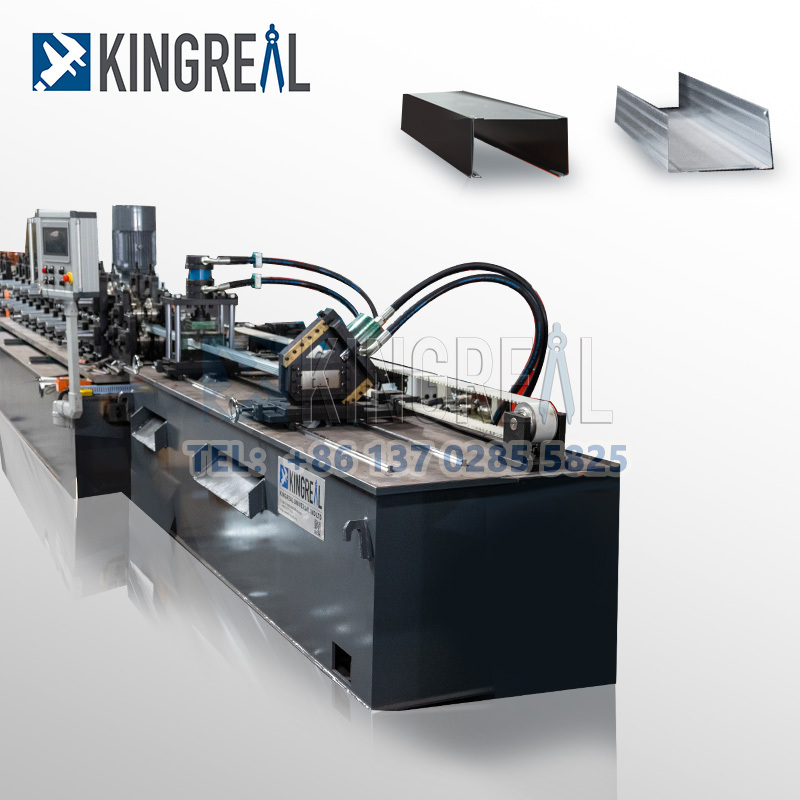

Gypsum Channel Making Machine

KINGREAL gypsum channel making machine is for various sizes of gypsum channel production with high speed, up to 80m/min, can be equipped with a automatic packaging machine or protective shield.

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video About Gypsum Channel Making Machine

Description Of Gypsum Channel Making Machine

KINGREAL gypsum ceiling channel machine has the characteristics of fast speed, automatic width adjustment, and automatic stacking, which can produce gypsum channels of different sizes. It is mainly composed of decoiler, main roll forming machine, flying punching and shearing station, automatic stacking machine, etc. These precision parts work together to ensure the efficiency and stability of the gypsum drywall partition channel machine.

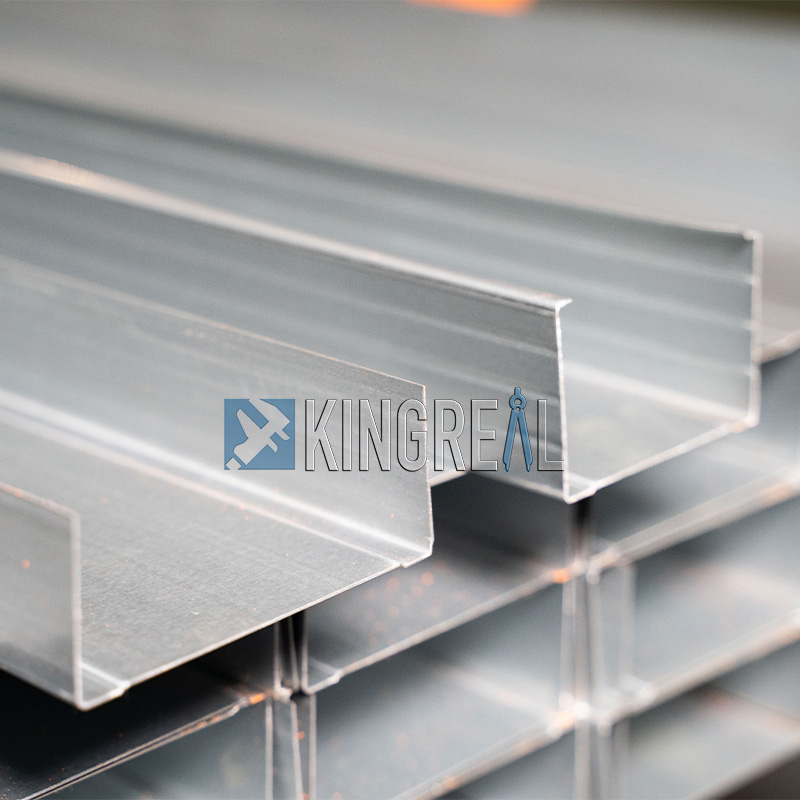

Gypsum channel provides a sturdy support frame in the movable partition system, which can effectively support gypsum board or other partition materials. And it also enhances the sound insulation effect and aesthetics. Its flexibility and easy installation make the layout adjustment of the space simple and efficient.

Parameters Of Gypsum Channel Making Machine

| Raw Material | GI Strip |

| Coil Thickness | 0.3-1MM |

| Working Speed | Up to 80M/Min (without auto packaging unit) Up to 60M/Min (with auto packaging unit) |

| Roll Forming Main Motor Power | 18.5KW |

| Hydraulic Station Motor Power | 11KW |

| Width Adjustable Servo Motor | 1.8KW |

| Power Supply | AC415V, 50HZ |

| Total Power | 40KW |

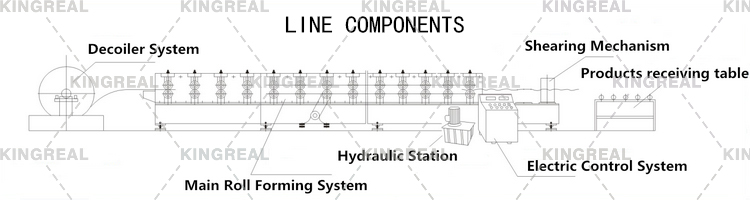

Working Process Of Gypsum Channel Making Machine

Decoiler system - Main roll forming system - Hydraulic station - Electric control system - Shearing mechanism - Receiving table - Auto packaging unit

Main Components Of Gypsum Channel Making Machine

Hydraulic decoiler

KINGREAL gypsum channel patti making machine is equipped with advanced hydraulic decoiler, which significantly improves the efficiency of raw material feeding.

Compared with the traditional manual expansion method, hydraulic expansion realizes fully automated operation, reduces manual intervention and is easier to operate. The design of the hydraulic system makes the feeding process smoother and ensures the stability and safety of the material. The system has higher reliability and can maintain consistent performance under different workloads with efficient hydraulic control, ensuring the safety and efficiency of the production process.

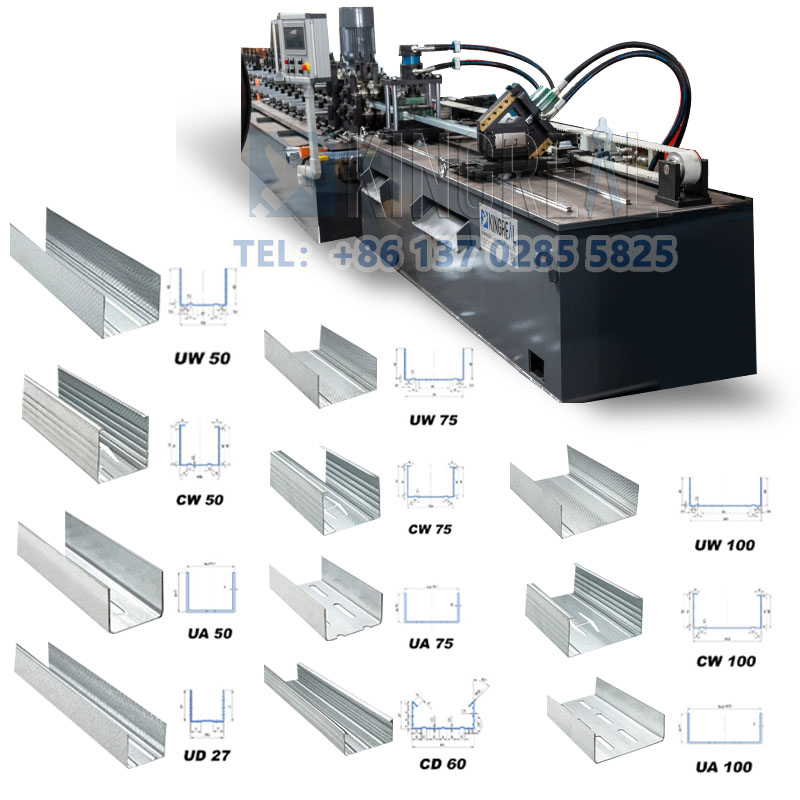

Roll Forming machine

KINGREAL roll forming machine uses carefully designed high-quality rollers that can bend and shape metal during processing without causing any damage or deformation. The forming machine has flexible adjustment functions. Just enter the corresponding parameters on the control panel, and the machine can automatically adjust the width to meet the production needs of gypsum channels of different sizes. The production speed of forming can reach up to 80m/min, ensuring stable operation under high load conditions and providing customers with efficient production solutions.

Fly punching and shearing

During the gypsum channels processing, KINGREAL's flying punching and shearing system completes the punching before cutting, and the whole process does not need to stop, which greatly saves time.

The system has fast punching and cutting speeds and high precision, ensuring that the size and hole type of each gypsum channel can meet the standard. By replacing different punching dies, the gypsum channel patti making machine can flexibly meet the production needs of various hole types and meet the specific requirements of different customers.

Automatic packaging machine

After the gypsum channel is manufactured, it will be transported to the automatic packaging unit for packaging and stacking. The entire stacking process does not require manual operation, ensuring the optimization of the production process. It not only improves production efficiency, but also realizes automation to the greatest extent and reduces labor costs. The introduction of this component further improves the overall efficiency of the gypsum ceiling channel machine.

Advantages Of Gypsum Channel Making Machine

1. Complete Production Solutions

KINGREAL is committed to providing customers with a complete set of flexible production solutions, covering heavy-duty, light-duty and simple-duty gypsum channel making machines to meet customers with different budgets and production needs.

- Heavy duty gypsum channel making machine

Designed to handle thicker metal materials (0.35-1.05mm), suitable for applications requiring high strength and durability, such as large-scale construction projects and industrial uses.

- Light duty gypsum channel making machine

Suitable for processing thinner metal materials (0.4-0.7mm), especially suitable for small and medium-sized enterprises and light-load production needs.

- Economical gypsum channel making machine

Provides an affordable option for customers with limited budgets. This machine can process thinner metal coils and produce gypsum channels without punching holes. It is suitable for start-ups or small factories.

Economical gypsum channel making machine

Light duty gypsum channel making machine

Heavy duty gypsum channel making machine

2. Technological Innovation

(1) Fully automatic packaging

In a new project with a Mexican customer in 2024, KINGREAL innovatively equipped the gypsum channel making machine with an automatic packaging. After the gypsum channel channel is manufactured, it will be automatically transferred for packaging operations, which significantly reduces manual intervention and improves production efficiency.

(2) Multiple options for adding logo devices

- Roller customization

KINGREAL provides customized roller services. Customers can engrave specific patterns on the roller according to their needs, and produce gypsum channels with unique appearance through rolling forming, which enhances the market recognition of the product.

-Inkjet coding

Using advanced inkjet technology, the customer's logo can be directly engraved on the gypsum channel after the metal coil is fed into the press for forming. This high-precision processing method not only enhances the personalization of the product, but also enhances the brand's exposure.

(3) Safety protection system

KINGREAL attaches great importance to production safety and proposes to add a protective shield device to the gypsum channel making machine. This design is intended to protect operators, prevent accidental injuries, and ensure the safety and reliability of the gypsum channel making machine during operation.

3. Perfect After-sales Team

KINGREAL is well aware of the importance of after-sales service for customer satisfaction and long-term partnerships, so KINGREAL has established a professional and efficient after-sales team to ensure that customers receive comprehensive support and help during use.

- Online answers to customer questions

KINGREAL's after-sales team provides 24-hour online service to answer customers' various questions about the machine at any time. Whether it is the operation, maintenance, or troubleshooting of the equipment, customers can contact KINGREAL's technical support team by phone, email, or online chat. KINGREAL's professional technicians will provide detailed and professional answers based on the customer's specific questions to ensure that customers can use the equipment efficiently and smoothly.

- Offline machine installation service and operation guidance

KINGREAL can provide customers with on-site installation and operation guidance services. KINGREAL's engineers will personally go to the customer's factory to be responsible for the installation and commissioning of the equipment to ensure that the machine runs in the best condition. During the installation process, the engineer will explain the various functions and operation procedures of the equipment in detail to help customers better understand how to use the equipment.

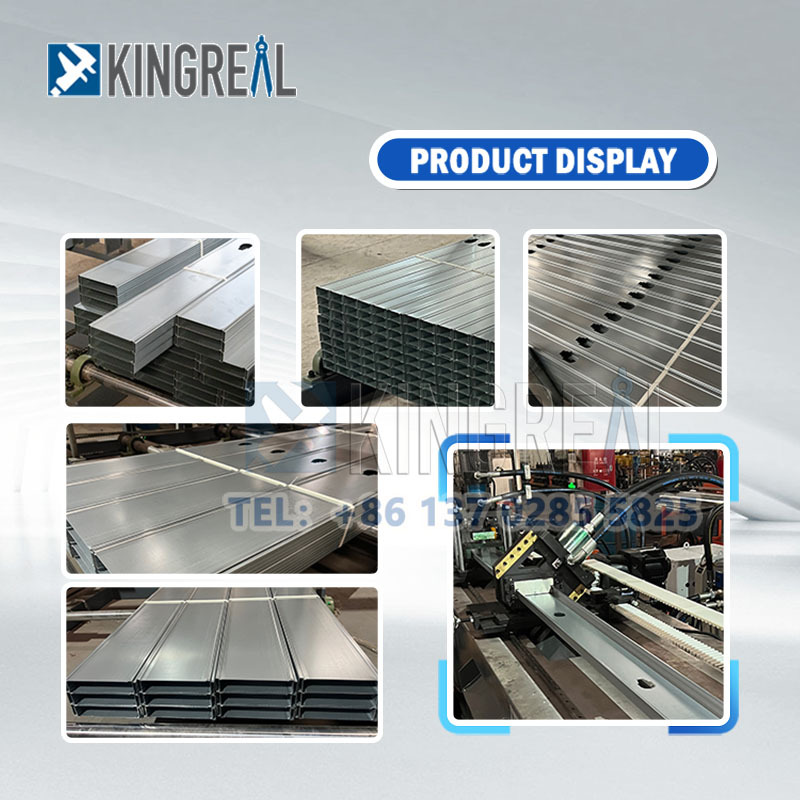

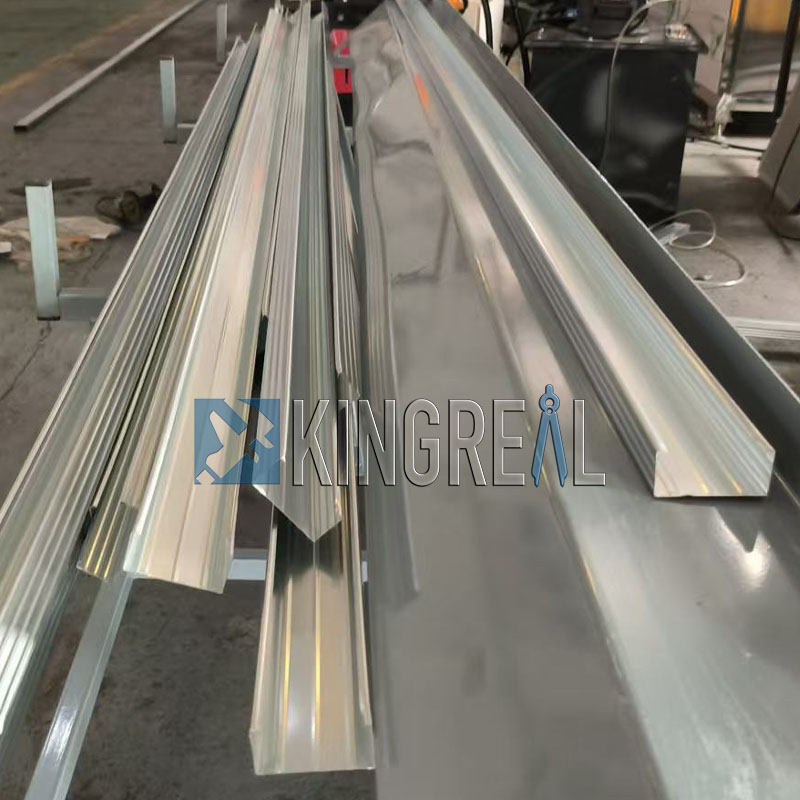

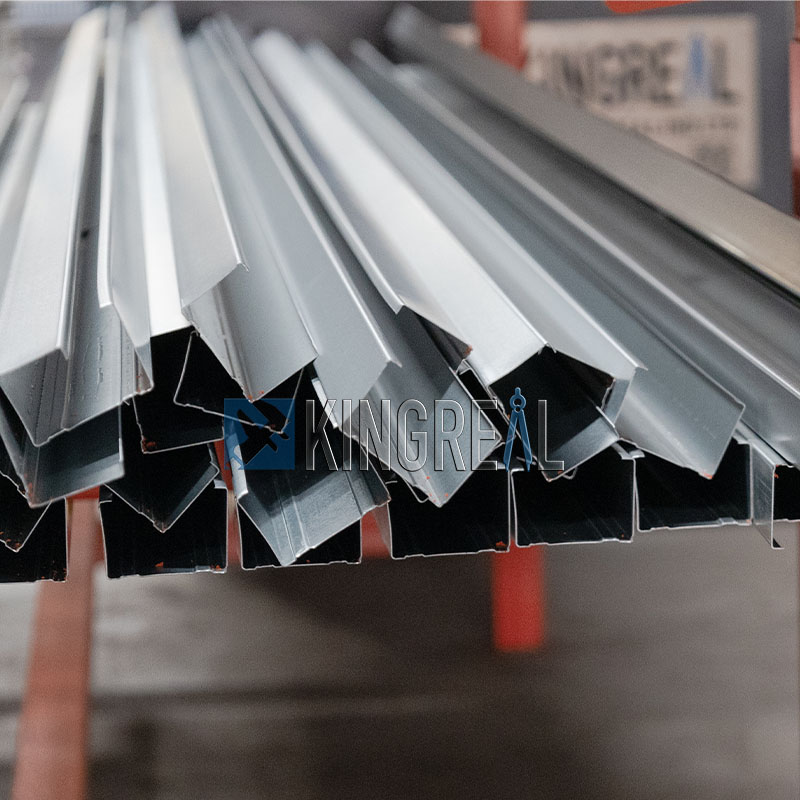

Product Display

After the gypsum ceiling channel machine is manufactured, KINGREAL strictly follows a systematic trial process to ensure that the equipment can produce high-precision gypsum channels that meet the specific production needs of customers. The trial process includes comprehensive testing of various performance indicators of the equipment, such as production speed, finished product size, stability and consistency, etc., to ensure that each machine is strictly inspected before delivery and meets industry standards. Only after confirming that the equipment can stably and efficiently produce products that meet the requirements will KINGREAL send the gypsum drywall partition channel machine to the customer's factory.