High Speed Metal Stud And Track Roll Former

KINGREAL offers full solution for ceiling profiles with high speed roll forming machine according to the customers drawinga or specific needs. The High Speed Metal Stud And Track Roll Former were successfully transported to Russia, Qatar, Turkey and India. KINGREAL have a lot of experience in designing and manufacturing machines and in transportation and after-sales service, so please feel free to contact us!

- KINGREAL

- China

- 90 Days

- 9999

- Information

- Download

Video Display

Whole Solutions Of Ceiling Profile

KINGREAL offer full solution for ceiling profiles high speed production, these machines including

1.Steel C channel profile roll forming machine

2.Steel U channel profile roll forming machine

3.Steel furring hat channel making machine

4.Flexible Stud and tracks making machine

5.Angle profile channel making machine

High Speed Metal Stud And Track Roll Former Description

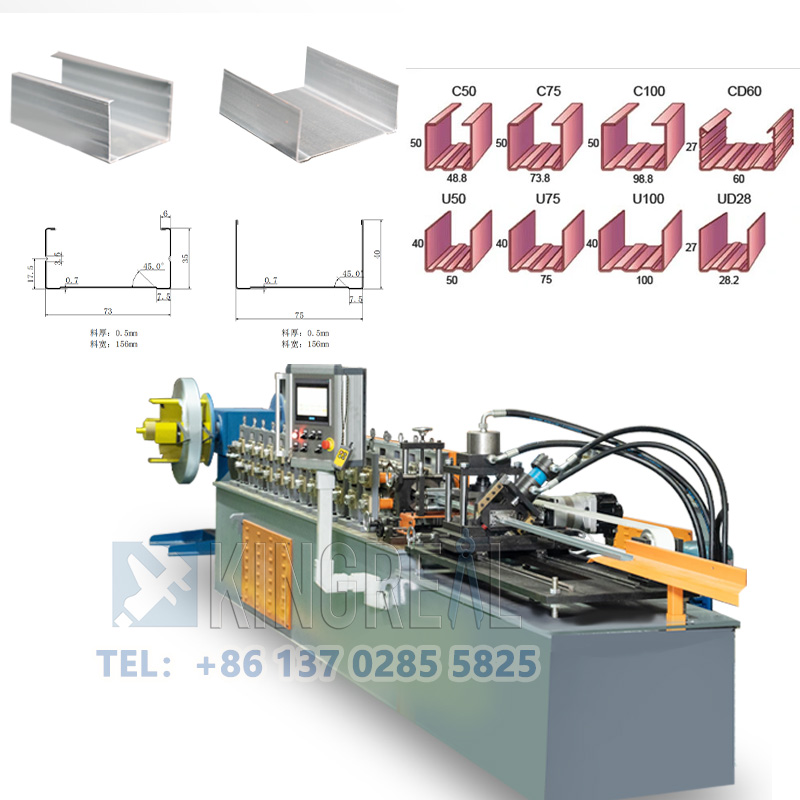

KINGREAL High Speed Metal Stud And Track Roll Former is one of KINGREAL most featuring products, and it is featured with high speed output (up to 120m/min), full automatic running (auto stacking system for your choice), easy to operate, etc. The basic structure of C channel profile making machine is decoiler, continuously cold roll forming, hydraulic follow shearing, auto stacking system, etc.

Metal Stud And Track Machine Components

-Double heads decoiler -High speed cold roll forming -Combi structure for your choice to produce different steel profiles on one machine -Machine protection -Hydraulic fly shearing -Auto stacking system for your choice. |  |

Technical Specification

| Machine Name | Metal Stud And Track Machine |

| Products Name | C-Shape Profiles, U-Shape Profiles |

| Products sizes | As per requirements |

| Automation | Manual Operation/Full-Automatic Production with PLC |

| Certificate | CE certificate, ISO 9001 certificate |

| Machine Power | 380V 50HZ or according with customers‘ request |

| Speed | 0~120m/min adjustable |

| Main Features | Equipped with air cooling system, Famous brand hydraulic system, light curtain safety protection |

Main Components Details

Double heads decoiler The double-head decoiling machine is mainly used for unwinding raw materials for high-speed keel forming machine. Materials can be loaded when the machine is working, therefore ensure the production line can continuously work at high speed. In addition, the machine can be used for multi-size production with multi-spec keel forming machines. It is time-saving in changing materials and efficiency-improving. |  |

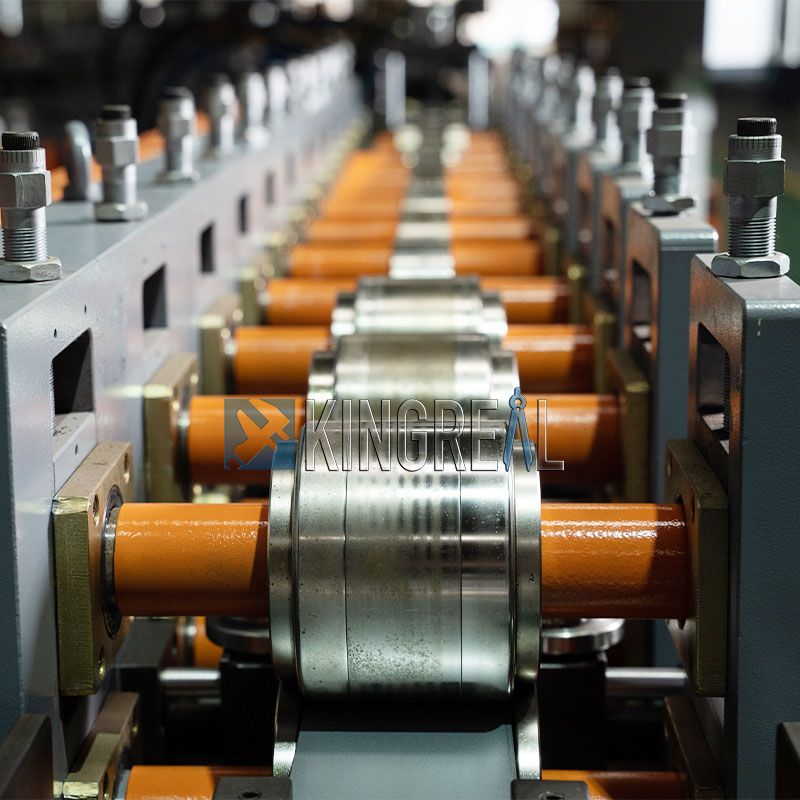

| High Precision Cr12MoV forming rollers Cr12mov mold steel, heat treatment hardness up to HRC 580-600. Which is processed by CNC machine. |  |

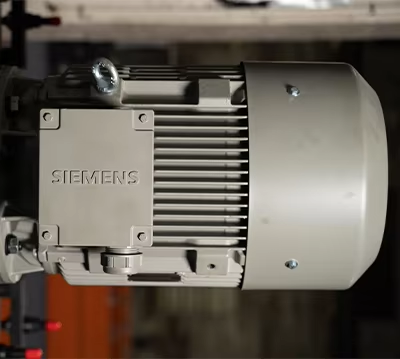

| Siemens Main Motor KINGREAL uses Siemens main motor for KINGREAL machine to ensure long-time working. Also, KINGREAL can customize the motor with different voltages. |  |

Metal Stud And Track Roll Forming Machine Advantages

1. High Speed Production

KINGREAL Stud And Track Roll Forming Machine can produce at speeds of up to 120M/min, and is equipped with double-head decoiler, high-quality multiple sets of rollers, and shearing equipment, which effectively increases the machine‘s productivity and makes it the preferred choice for factories with high production demands.

2. Width Adjustable For Different Size Profiles

The production of different size profiles by adjusting the width of the rollers is one of the most unique designs of KINGREAL. It solves the need for customers to produce multiple sizes, avoiding the need to purchase multiple machines and effectively reducing production costs.

3.Professional technical support

KINGREAL has a wealth of experience in machine design and manufacturing with numerous samples of different profiles. And KINGREAL is able to design specialized production solutions according to the drawings or samples provided by KINGREAL customers.

4. Auto Package Machine

KINGREAL This partition wall keel molding machine speed can reach up to 120M/min, so that manual packing requires a high number of workers and professionalism, and more labor cost expenditure. Therefore KINGREAL specially designed baler program can realize the express fully automatic packing.

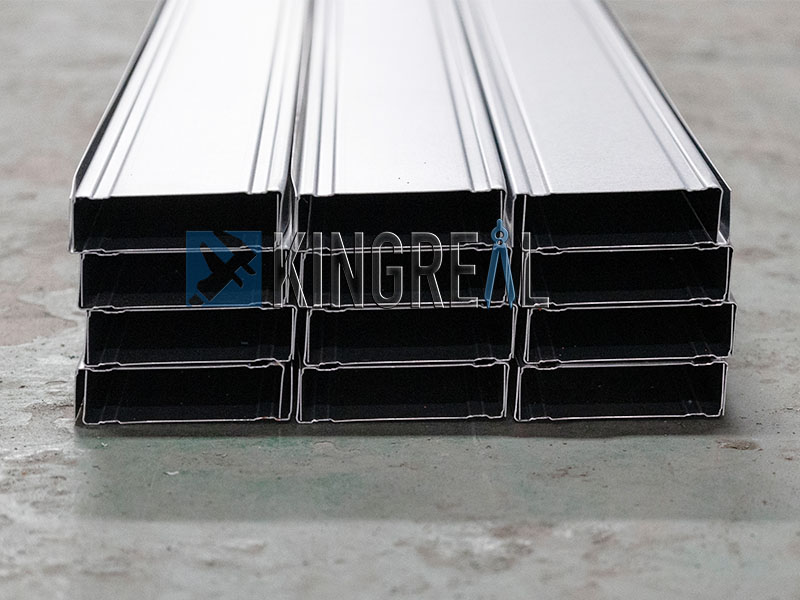

Product Display

KINGREAL's gypsum stud and track machine can efficiently produce c studs and u tracks of various specifications to meet different construction needs. This gypsum stud and track machine is used to process galvanized sheets with a thickness ranging from 0.35mm to 1.2mm, ensuring the wide applicability and processing flexibility of the material. More importantly, KINGREAL's stud and track forming machine can not only produce both stud and tracks, but also greatly save customers' investment costs in equipment purchase. This innovative design enables customers to complete a variety of production tasks on a single machine, improves production efficiency, and reduces operating costs, making it an ideal choice in the industry.

Installation Service

In order to help KINGREAL customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.

Customer Visit

KINGREAL sincerely welcomes customers from all over the world to visit KINGREAL factory. KINGREAL staff will warmly receive and accompany customers throughout the process, introduce the overall situation of the factory to customers, and lead them to visit various workshops, including raw material workshops, machine manufacturing workshops, test machine workshops and finished product storage rooms. Customers will have the opportunity to watch the operation of the gypsum stud and track machine up close, participate in the operation, and have a deeper understanding of KINGREAL's products.

After customers have a more comprehensive understanding of the stud and track forming machine, KINGREAL will invite customers to the conference room to discuss manufacturing solutions with KINGREAL engineers. According to the customer's drawings and production needs, KINGREAL will provide customized machine manufacturing solutions.