- Home

- >

News

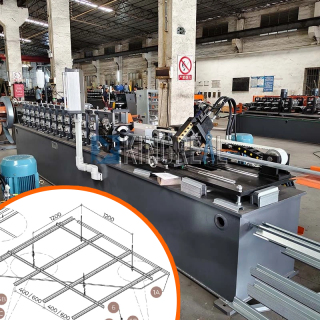

In the production and manufacturing system of the suspended ceiling system, the main channel making machine, as a key device in the false ceiling channel machine, provides important basic profile support for the construction of the ceiling system. U channel roll forming machines typically use aluminum, GI steel or PPGI with a thickness of 0.4-1.2mm as metal raw materials. Under the coordinated operation of a series of precision components such as decoiler, roll forming machine, cutting station and output table, u channels that meet the installation requirements of ceiling systems are ultimately produced. This u channel produced by the main channel making machine is often used in practical applications in combination with the furring channels and wall angles produced by the omega channel machine and l-shaped profile making machine, jointly applied in the installation of suspended ceiling systems, providing customers with a complete and efficient suspended ceiling system solution to meet the suspended ceiling construction needs in different building scenarios.

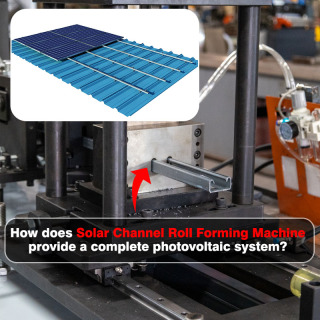

Solar Channel Roll Forming Machine produces Solar Channels of different sizes to provide safe and reliable support for solar panels, and is a key component in the solar panel installation system. It is favored for its durability and easy installation. Among them, in a complete photovoltaic system, both the roof tile making machine and the solar channel making machine are indispensable parts. Therefore, only when they are used in combination can a complete photovoltaic system be formed. In this article, KINGREAL will give you a detailed introduction on how the solar channel roll forming machine and the roof tile making machine are used together to provide customers with a complete photovoltaic system.

In the fast advancing photovoltaic sector of today, consumers' requests for photovoltaic brackets are rather varied. KINGREAL knows well that consumers who buy solar channel roll forming machines have extremely varied finished product size requirements, thus market demands cannot be satisfied by solar channel making machines with a single specification. To meet this demand, KINGREAL engineers have created a formulating solar channel roll forming machine capable of producing photovoltaic brackets of several sizes. Apart from enhancing production efficiency, this creative technology offers consumers adaptable answers.

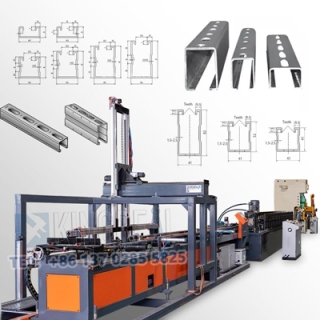

Slotted channel framing making machines play a vital role in the modern renewable energy industry. These slotted channel roll forming machines are not only used to produce slotted channels that meet the needs of photovoltaic power generation projects, but also ensure the installation and fixation of photovoltaic panels, thereby improving the overall efficiency and stability of photovoltaic systems. With the increase in global demand for clean energy, the application of slotted channel framing making machines has gradually expanded to multiple fields and has become a key equipment to promote the development of renewable energy. In this article, KINGREAL will discuss with you the common application areas of slotted channel roll forming machines. If you are interested in slotted channel framing making machines, welcome to consult!

With the rapid development of renewable energy, the importance of the unistrut channel roll forming machine in solar panel mounting systems has become increasingly prominent. This solar mounting strut channel machine can be used to manufacture metal channels used to support solar panels. It can produce channels of different shapes and sizes according to project requirements to meet diverse market needs. In this article, KINGREAL will take a deep look at the functions, application areas, machine advantages, and importance of the unistrut channel roll forming machine in modern manufacturing.

KINGREAL solar mounting strut channel machine is a kind of equipment specially used for manufacturing solar mounting strut channel for solar panel installation. It produces solar mounting strut channels that meet various installation requirements by bending, cutting and forming metal strips. These pv support brackets are not only used to support solar panels, but also provide stable support in different environments and installation conditions. The design of solar mounting strut channel roll forming machine is to improve production efficiency and reduce costs, thereby promoting the rapid development of the photovoltaic industry.

In the modern construction industry, false ceiling channel has gradually become the mainstream material in the field of building decoration because of its advantages of light weight, high strength, convenient construction, environmental protection and durability. As the core equipment for false ceiling channel production, the importance of false ceiling channel machine is self-evident.

Stud and track making machines are specifically designed for the production of gypsum ceiling profiles (studs and tracks). These profiles are essential components in suspended ceiling systems and are commonly used in residential, commercial and industrial buildings due to their light weight, thin thickness and fast assembly speed.

Photovoltaic brackets are structural devices used to install and support solar photovoltaic modules, ensuring that solar panels can be firmly fixed in the predetermined position after installation and receive sunlight at a reasonable angle, so as to achieve the best photovoltaic power generation efficiency. Photovoltaic brackets are usually made of metal materials (such as aluminum alloy, carbon steel and stainless steel, etc.) or other weather-resistant materials.

A customer in Saudi Arabia learned from a friend that KINGREAL is a professional metal processing equipment manufacturer, and is famous for its high-quality machines and excellent services. The customer hopes to purchase a false ceiling channel machine to improve the production efficiency and product quality of his company.

Unistrut roll forming machine is one of KINGREAL's hot-selling products, with more than 50 units sold. KINGREAL has established friendly cooperative relations with customers from Russia, India, Poland, the United States, Canada and other countries, especially Canada, Mexico, the United Kingdom and other countries, and has precisely customized strut channel machine. With rich manufacturing experience and a deep understanding of local market needs, KINGREAL can accurately meet customers' needs for solar panel roll forming machine parameters.

Stud and track machine is an important equipment in the field of building materials production. It is mainly used to produce drywall studs and tracks used in construction. These are widely used in the installation of suspended ceilings, partitions and frame structures. They have the advantages of light weight, high strength, fire resistance and corrosion resistance.