Shelf Column Post Roll Forming Machine

KINGREAL is a professional cold bending roll forming machinery equipment manufacturers. KINGREAL shelving system equipment including Shelf Column Post Forming Machine and Storage Rack Panel Roll Forming Machine.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

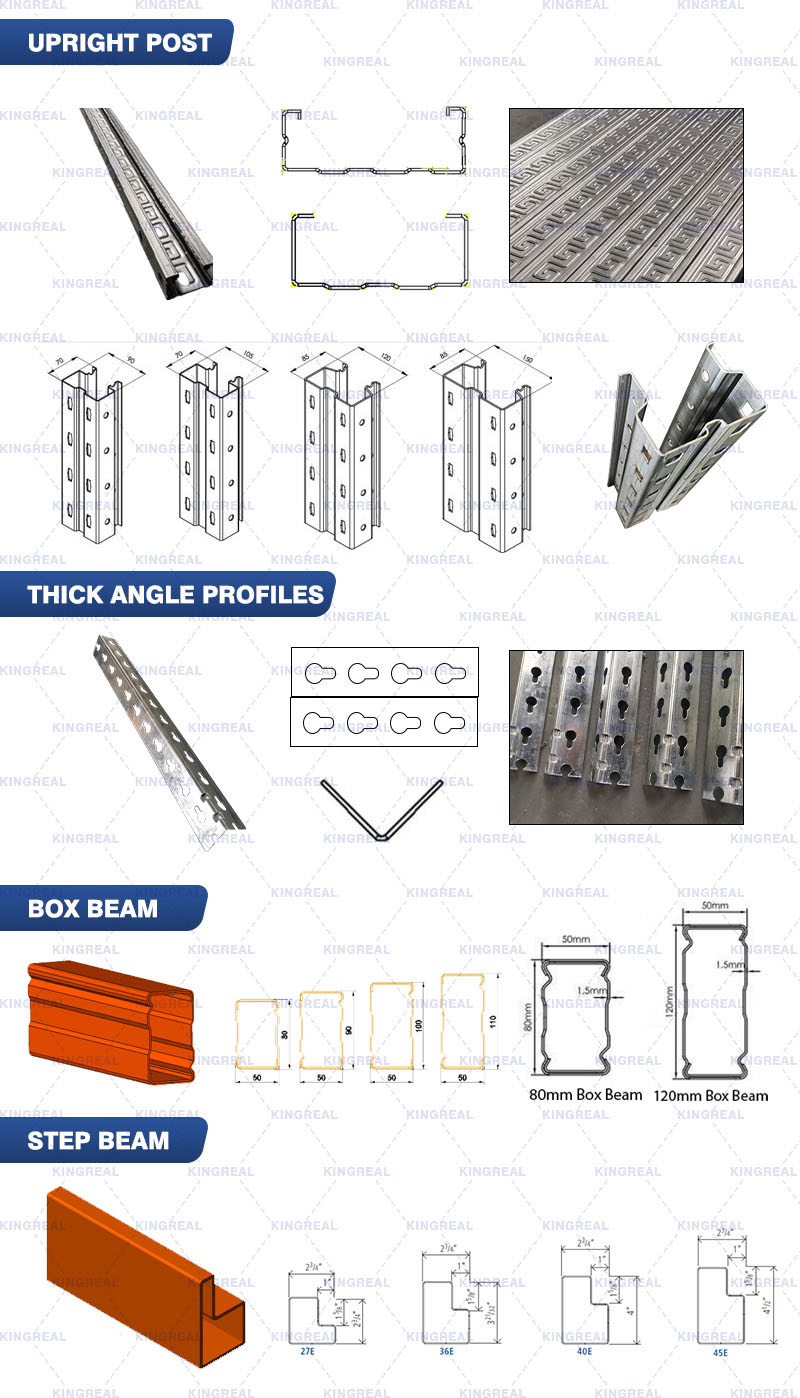

Description of Rack Upright Making Machine

The Rack Upright Making Machine adopts industrial control PLC and man-machine interface to realize production automation; by inputting product length, hole distance, quantity and other parameters, the process of punching, forming and cutting can be completed at one time during production; continuous production without stopping to ensure product Stable quality and accurate size.

The Storage Rack Roll Forming Machine is mainly composed of decoiler, power leveler, CN servo feeding mechanism + punching mechanism, roll forming machine, electric control system, hydraulic system, mechanical tracking and shearing mechanism and other components.

Equipment Composition and Description

Part Name | Description | Specification |

Uncoiler | The feeding frame is a cantilever umbrella structure. It consists of a base, a discharge head, and a stretch structure | 1. Inner hole of material roll: ø508±30mm 2. Outer diameter of material roll: ≤ø1800mm. |

Power leveling machine | The leveling machine is composed of a sheet material introduction device, a guide device adjustable on both sides, and a leveling roller. It adopts seven-roller structure for leveling and has power. | 1. Leveling roller: 7 rollers, material: 40Gr fine turning, after quenching and tempering, fine grinding, hard chrome plating 2. Effective width: 0-320mm |

Storage pit (or storage rack) | 2 groups, coil storage, between the leveling mechanism and the punching mechanism, between the punching mechanism and the forming machine, the storage pit is dug according to the process design (or equipped with storage Rack), equipped with automatic storage control system. | / |

Servo feeder + punch + mold | 1. Servo feeder: It is composed of guide, lead roller, servo motor, transmission mechanism and control system, which can feed the punch quickly and accurately. 2. Punching mold description: front and rear combined molds, pneumatic selection action unit, single set of molds can adjust the spacing | 1. Feeder model: NCF-300 2. Punch: Provide power for punching. 3. Punch specifications: Recommend JH 21-80 punch, Yangli brand. 4. Mold and process: a set of combined punching die, meeting two punching types |

Roll forming machine | 1. The main machine of the forming machine adopts the arch structure, adopts reduction box + gear distribution box transmission, and is equipped with guiding mechanism, rolling mechanism and other components. 2. Frame: integral welding of national standard section steel (according to ship component standard) 3. The number of archway: about 16-17 sets of horizontal, 4-6 sets of side auxiliary rollers Appearance treatment: After the welding position is polished, degreasing, and putty scraped, the primer is sprayed, and the top coat is sprayed twice with high-grade polyurethane paint. The appearance is finely treated and beautiful. | 1. Forming roller: material GCr15 bearing steel forging, overall quenched in salt bath furnace, hardness of HRC58-62°, hard chromium plating 0.05mm on the surface. 2. Spindle: high quality material 40Cr, diameter ¢80mm, quenched and tempered HB250-280; fine turning. 3. Transmission mode: motor + reducer + gear distribution box. |

| Tracking hydraulic shearing machine | mechanical tracking, mechanical sizing, non-stop hydraulic punching | 1. Cutting method: tracking hydraulic profiling punching (no waste dislocation punching) 2. Tracking method: mechanical tracking (pneumatic compression tracking) |

| Electronic control, transmission, hydraulic station | 1. Electrical control system: three sets of electric control cabinets and auxiliary electrical configuration (three sets of uncoiling, punching, and rolling, the rolling electromechanical cabinet is the main electric control cabinet, adopting independent floor type) Electricity is integrated, and the electric cabinet can be operated independently | 1. Roller drive system: AC motor + K series reducer + gear distribution box 2. Hydraulic system: A set of hydraulic station and auxiliary facilities provide power for punching and cutting off finished products. |

Features Of Shelf Colum Post Making Machine

High capacity punching press KINGREAL Rack Upright Making Machine adopted 125 tons high capacity hydraulic punching press for ensuring high-speed and continuous stamping operations.Support long-term forming operations KINGREAL technical team adopt Cr12MoV as the material of rollers. Moreover, the rollers are made through vacuum heat treatment, whch can highly improve the plasticity, toughness and fatigue strength of the material. Combining the two, overall mechanical properties are improved as a result, it is benefit for long-term forming operations. High quality components Structural parts and standard parts comply with national standards. The bearings are of well-known Havalo brands, and other standard parts are of well-known domestic and foreign brands. |  |

Three Types Of Shelf Column Machine

KINGREAL is dedicated to providing customers with high-quality upright rack machines to meet the needs of different shelving systems. KINGREAL has designed three types of shelf column machines for light shelving systems, medium shelving systems, and heavy shelving systems. These pallet storage racks machines not only have excellent performance, but can also be customized according to the specific needs of customers.

● Supermarket rack machines for light shelving systems: It uses efficient production processes to quickly produce lightweight, easy-to-install columns suitable for home and small commercial environments.

● Supermarket rack machines for medium shelving systems: It has a stronger load-bearing capacity and are suitable for medium-sized supermarkets and warehouses, ensuring stability and safety in daily use.

● Supermarket rack machines for heavy shelving systems: Its designed for large-scale warehousing and industrial applications, and can handle higher loads to ensure the safe storage of goods.

What Are the Dimensions of the Shelf Column?

The Shelf Column Roll Forming Machine can produce shelf column profiles of 120×69, 100×69, 80×69 with thickness ranging from 1.2-2.5mm. To change the product model, use the quick-change haval sleeve (the haval sleeve adopts the split buckle form); just install the haval sleeve to the corresponding position according to the specification configuration, lock the nut, and replace the cutting die.

Other Featuring Roll Forming Machine

Years of penetration into the roll forming machine market, KINGREAL have stocked many successful cases and localized technical support experience:

1. Storage Rack Roll Forming Machine

2. Metal Roofing Machine

3. U Channel Roll Forming Machine

4. Stud and Track Roll Forming Machine

5. T Bar Roll Forming Machine

6. Cable Tray Roll Forming Machine

Installation Service

In order to help our customers to solve machine installation problems, KINGREAL will provide both online and local installation services.

1. Online installation guide

- Photos and videos of machine will be sent

- Online group will be initiated to discuss together

- Regular video conference be held to keep communication and contacting

2. Local installation

KINGREAL will arrange engineers to go abroad to install the machine at the customer‘s place to ensure the normal operation of the machine, and will provide all technical guidance. Exact costs to be negotiated.