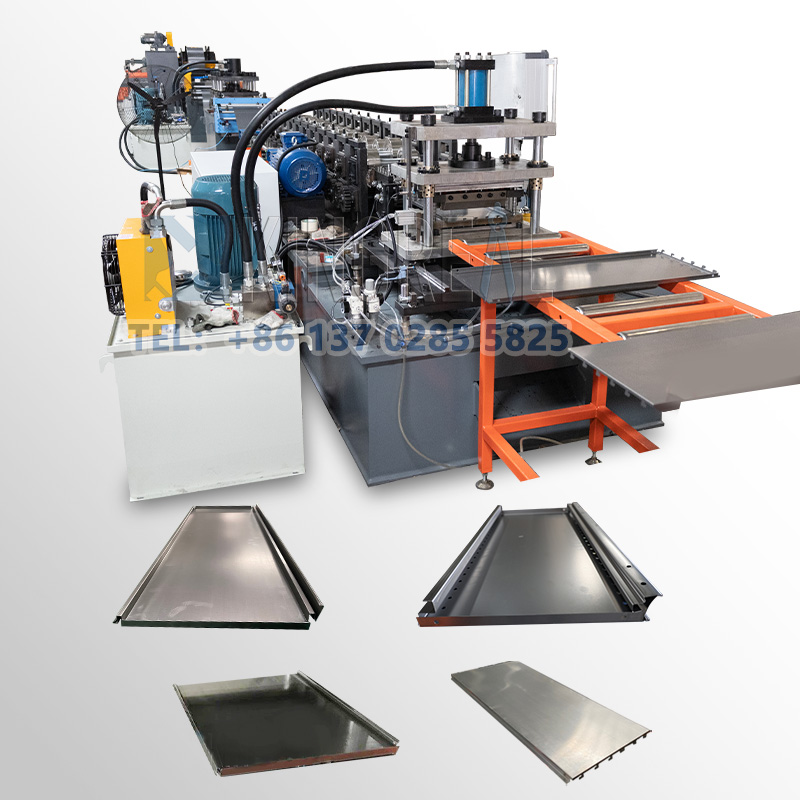

Shelf Panel Roll Forming Machine

KINGREAL can provide shelf panel roll forming machine, which is design for produce storage shelves, supermarket shelves and other profile. As a professional manufacturer in the field of molding machines in China, KINGREAL has rich experience in production and sales and can provide high-quality machines.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

Brief Introduction Of Shelf Panel Roll Forming Machine

KINGREAL provides Shelving and Racking Panel Roll Forming Machine for product the storage shelf panel, width of products is changeable thanks to our servo motor controlling system. Only need to wait for 10 minutes, the machine can switch to another width of products.

KINGREAL shelf panel roll forming machine is one of the most featuring products, with famous brands main motor and high-hardness CR12MOV rollers, 30mm thickness archway panels, our machine is ready to provide services for clients for an exceedingly long time.

KINGREAL also can offer full solution of shelving system making machine

- Shelf column forming equipment

- Shelf laminate forming machine

- Shelf beam (replacement beam) cold bending machine

- Shelf step beam (P beam) automatic production line

- Shelf reinforcement equipment

- Shelf label slot production equipment

- Shelf universal Angle steel production equipment

- Shelf bullet beam cold bending forming machine

Specification Of Shelf Panel Roll Forming Machine

| Raw materials | Gi Steel strip or stainless steel |

| Sizes | According with customers’ drawing |

Maximum forming speed | 30 m / min |

Roll Forming stands | 20-125 Rollers station |

Machine Power | ~ 35 KW |

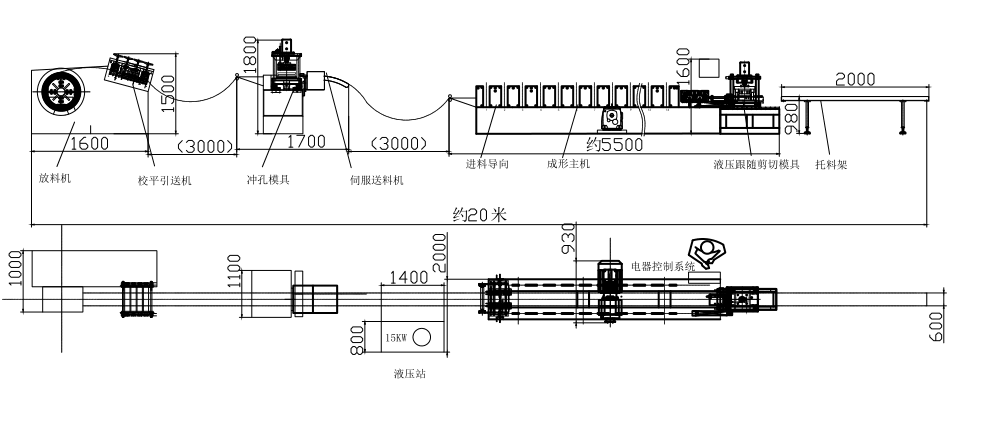

Structure Of Shelf Panel Roll Forming Machine

KINGREAL shelf equipment consists of: discharging, leveling, feeder, punching, forming machine, fixed length cutting, receiving platform, electric control box (PLC control), etc.

Decoiler - leveling - servo feeding - punching system - bilateral roller rolling forming - hydraulic automatic cutting and bending - receiving table - automatic welding.

Features Of Rack Shelf Panel Roll Forming Machine

1. The machine adopts PLC full-range intelligent control, and the automation program is high, safe and efficient. 2. The forming frame is welded using high strength channel steel. High strength and long service life. 3. The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment. 4. The material of the molding die is GCr15, quenching treatment, hardness: HRC 56-62 °C. 5. The transmission structure is gearbox transmission or chain transmission. |

|

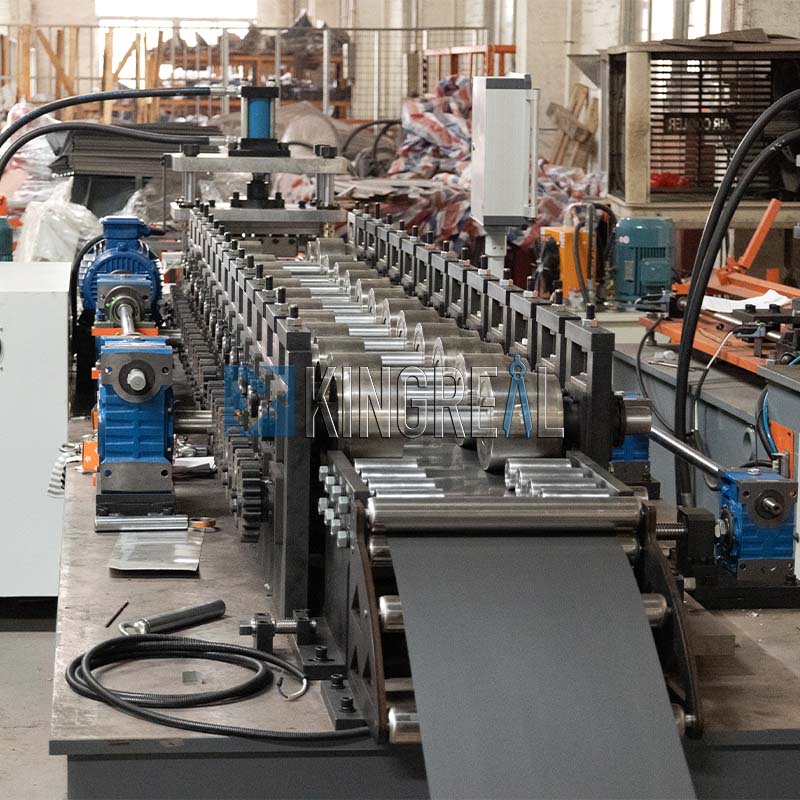

More Details About Shelf Panel Machine

KINGREAL's shelf panel machine consists of multiple precision components, including decoiler & straightener, punching machine, roll forming machine and cutting station. These components work together to ensure the efficient operation and superior performance of the shelf panel machine. Customer feedback shows that KINGREAL's shelf panel roll forming machine is easy to operate, runs smoothly, and has excellent product quality. At the same time, the design of the shelf panel machine also focuses on the convenience of maintenance to help customers reduce maintenance costs.

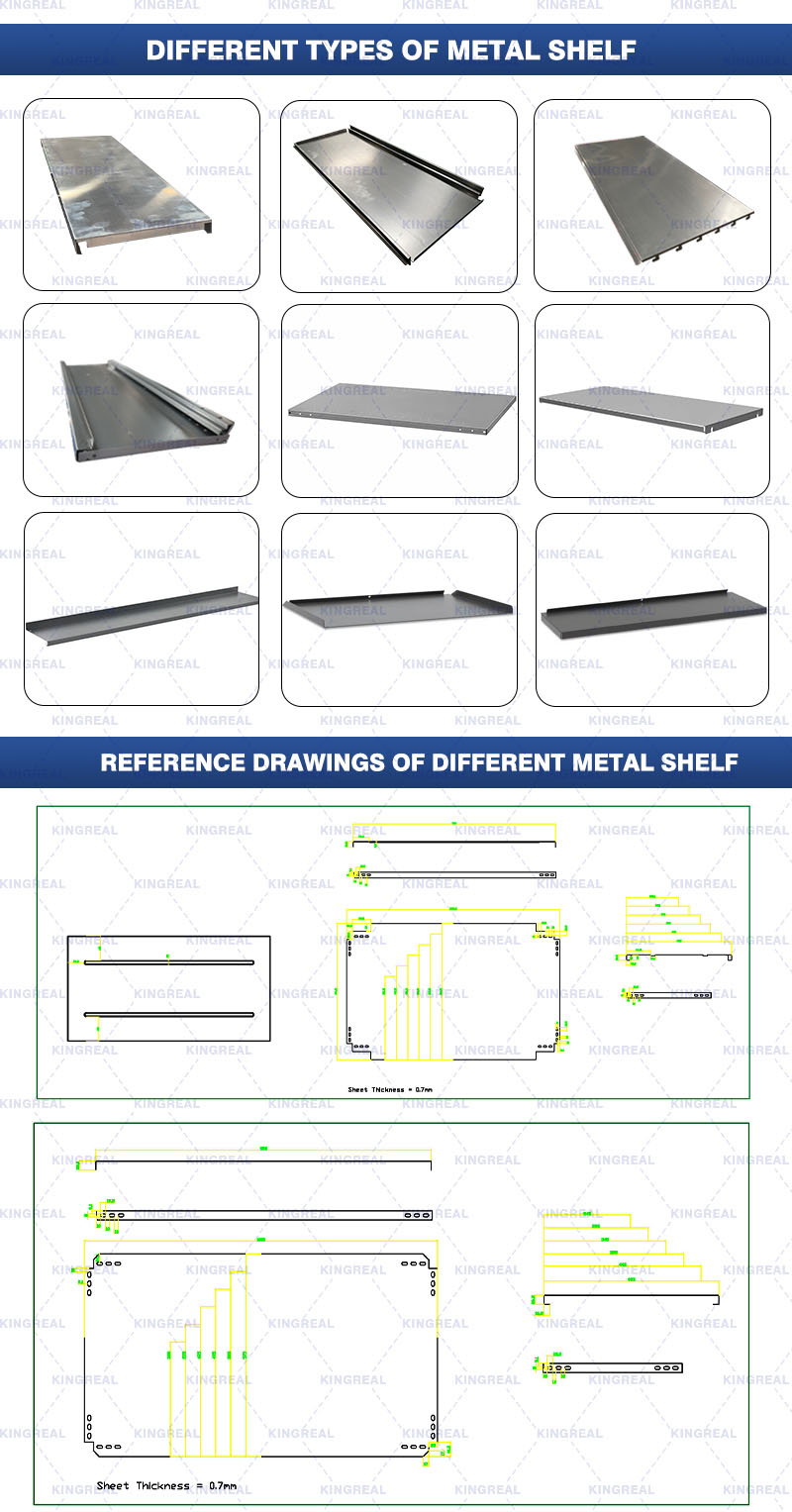

Reference Drawing About Metal Shelf Panel

KINGREAL's shelf panel machine can produce supermarket shelf panels of various types and sizes. KINGREAL's customized service ensures that the unique needs of each customer can be met. As long as the customer provides detailed drawings and fully communicates with KINGREAL's engineers, KINGREAL can tailor the most suitable shelf panel roll forming machine solution for you. Whether it is a standard size or a special design, KINGREAL can achieve it for you, so that your production needs can proceed smoothly.

Machine Quality Control

KINGREAL has established a strict quality control process to ensure that every production step meets the standards and requirements. This includes raw material procurement, production process, assembly, testing, etc. To ensure that every part of the machine meets quality standards. It has also passed the international CE certificate certification.

KINGREAL's Partners

As a professional roll forming machine manufacturer with more than 20 years of rich experience, KINGREAL has established close cooperative relations with customers from many countries. KINGREAL warmly welcomes all customers to come for exchanges and cooperation. In the interaction with customers from different countries, KINGREAL constantly gains new inspiration and inspiration. This diversified customer feedback enables KINGREAL to continue to improve, learn and innovate in each project, and promotes the upgrade and optimization of many roll forming machines. KINGREAL's goal is to ensure that it can better meet customer needs by continuously improving technology and services.

FAQ

1. Are you a manufacturer?

Yes, KINGREAL Machinery is a professional sheet metal processing machines manufacturer and supplier.

KINGREAL has been focusing on the field of machine manufacturing for more than 20 years.

2. How to visit your company?

KINGREAL factory is located in Foshan city, Guangdong Province. So there are two ways to our city.

One is by flight, direct to Foshan or Guangzhou Airport. Another is by train, direct to Foshan or Guangzhou station.

KINGREAL will pick you up at the station or airport.

3. What‘s your Warranty ?

12 months, during which all parts damaged because of quality problem will be changed for free.

4. What‘s your delivery Time ?

Within 45-60 days after receiving prepaid. Some machines in stock, can be delivered at any time.