Supermarket Storage Rack Panel Roll Forming Machine

KINGREAL Supermarket Storage Rack Panel Roll Forming Machine, shelf roll forming machine is widely used for cold roll forming of storage shelves, supermarket shelves, heavy-duty shelves and other profiles. We can supply whole solution of all this shelving system machine, please contact us!

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

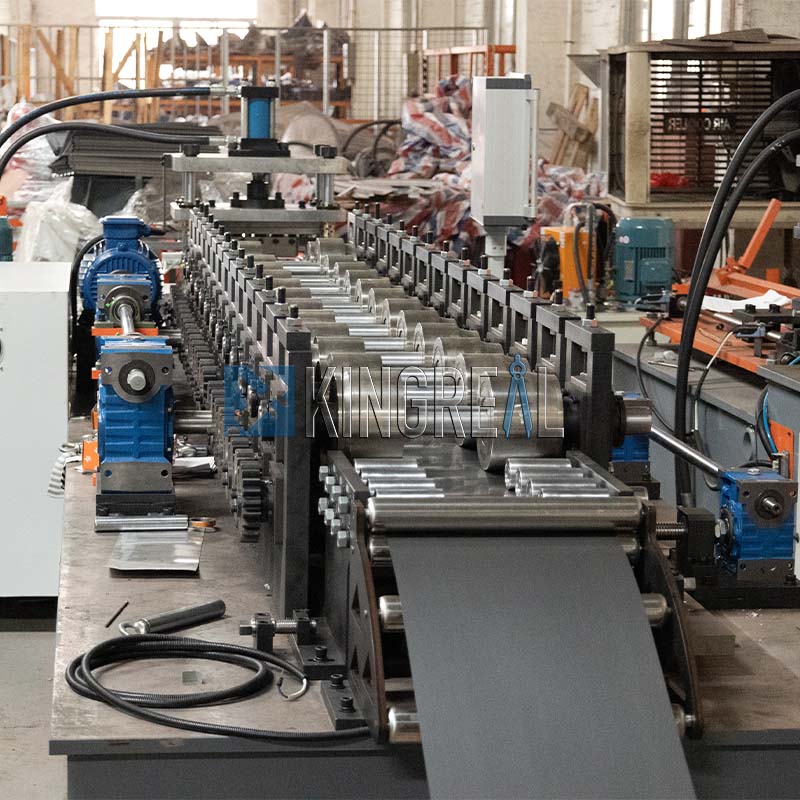

Brief Introduction Of KINGREAL Shelf System Roll Forming Machine

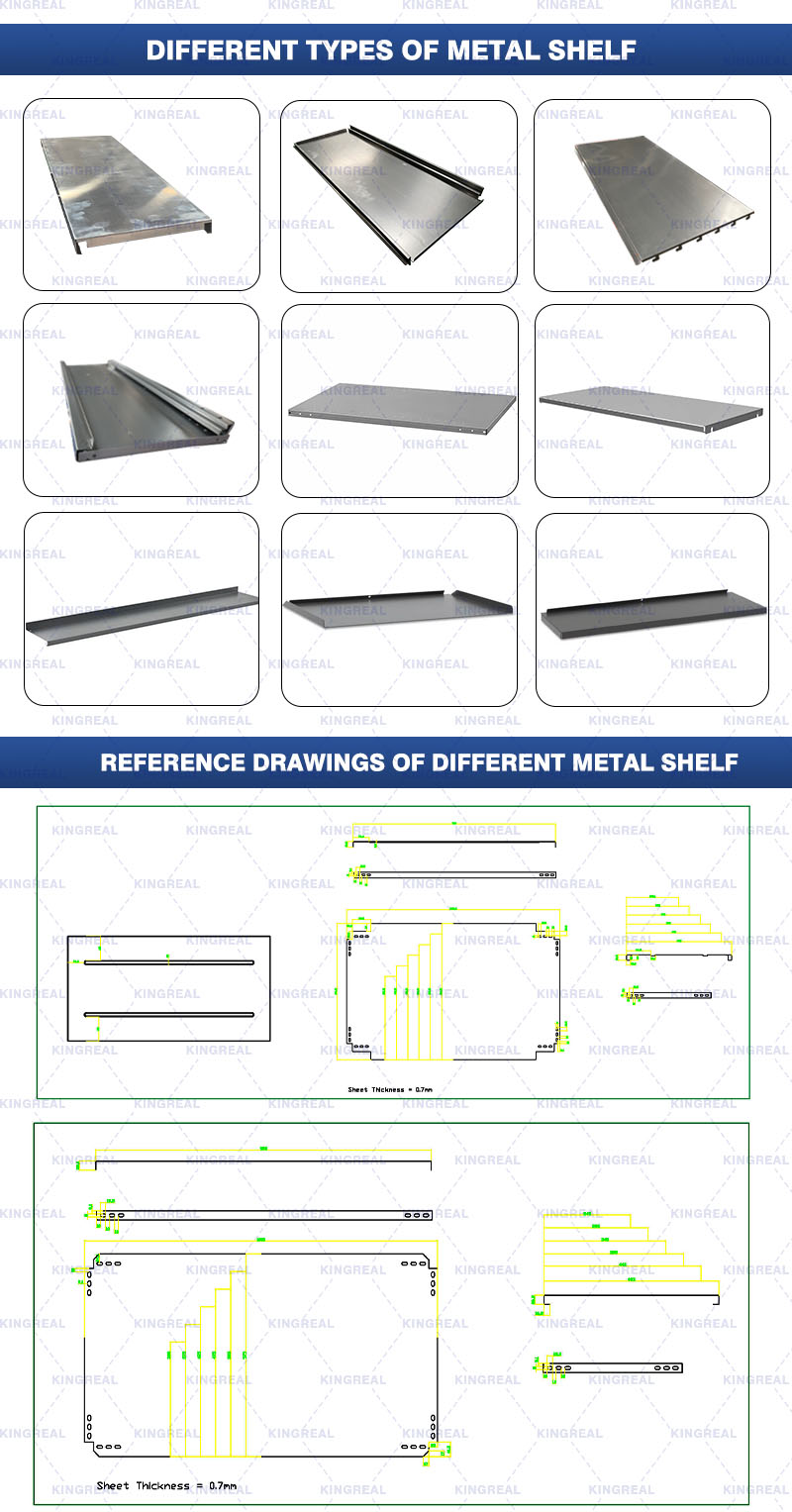

Supermarket Storage Rack Panel Roll Forming Machine is widely used for cold roll forming of storage shelves, supermarket shelves, heavy-duty shelves and other profiles. KINGREAL metal shelf rack panel forming machine adopts integrated design, integrating multiple processes in one machine, which greatly improves the production efficiency. Meanwhile, it is designed with advanced numerical control technology, and the machine is able to accurately control the size and shape of shelf laminates.

The use of shelf panel equipment to produce shelf profiles, which is low production cost, high efficiency and environmentally friendly materials, can be combined with production needs to manufacture automated production equipment, saving labor, making enterprises more competitive in the fierce market competition.

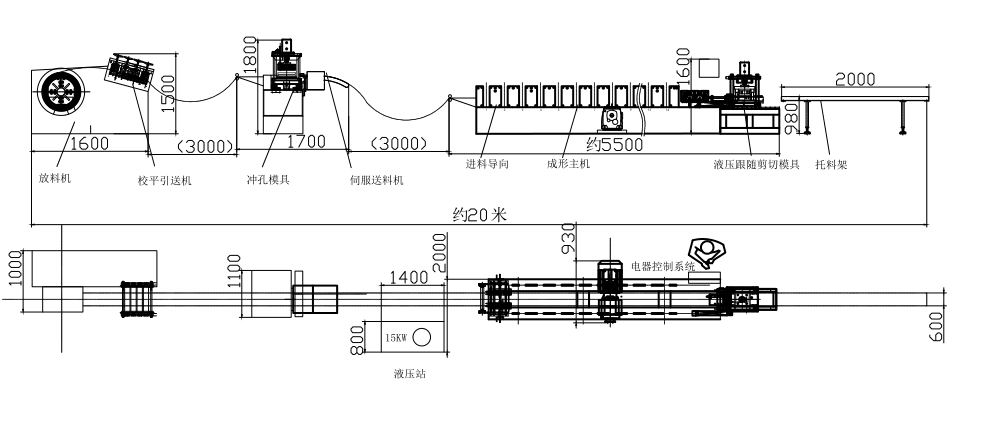

KINGREAL shelf equipment consists of: discharging, leveling, feeder, punching, forming machine, fixed length cutting, receiving platform, electric control box (PLC control), etc.

Mainly Include

- Shelf post roll forming equipment

- Shelf rack panel roll forming machine

- Shelf beam (Box beam) cold roll forming machine

- Shelf step beam (P beam) automatic roll forming production line

- Shelf reinforcement rib roll forming equipment

- Shelf label slot roll forming production equipment

- Shelf universal Angle steel roll forming production equipment

- Shelf bullet beam cold bending forming machine

KINGREAL Shelving Equipment Features

1. The machine adopts PLC full-range intelligent control, and the automation program is high, safe and efficient.

2. The forming frame is welded using high strength channel steel. High strength and long service life.

3. The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering treatment.

4. The material of the molding die is GCr15, quenching treatment, hardness: HRC 56-62 °C.

5. The transmission structure is gearbox transmission or chain transmission.

Shelf Panel Making Machine Production Process

Decoiler - leveling - servo feeding - punching system - bilateral roller rolling forming - hydraulic automatic cutting and bending - receiving table - automatic welding

KINGREAL Unique Design

1. This shelves panel automatic production line can produce different specifications of the board, integrates the numerical control to complete the punching, shearing, cold roll forming and folding process, greatly saving labor and improving work efficiency, replacing the traditional CNC punching machine, CNC bending machine, CNC shearing machine Combined function.

2. Different specifications are completed by numerical control. Punching different holes, you can choose to complete the stamping die. The roller press is adjustable by a combination of two machines.

Final Product Display

Who Are We?

KINGREAL Machinery is a professional sheet metal processing machines manufacturer and supplier. KINGREAL offers full automatic and high speed solutions mainly including roll forming machines, metal ceiling tile machines, metal perforation line, coil slitting lines, etc.

KINGREAL had helped our clients to build their factories successfully all over the world, such as Russia, Middle East, South Asia, South America, etc.

Quality Assurance

KINGREAL is a professional machine manufacturer with more than 20 years of experience, focusing on the production of high-quality supermarket storage rack machines. KINGREAL uses a strict manufacturing process to ensure that each storage rack roll forming machine can meet the high standards of customers.

1. Raw material selection

KINGREAL strictly selects raw materials with excellent quality and high hardness, and cooperates with well-known suppliers to ensure the reliability of materials.

2. Precision component production

KINGREAL uses advanced equipment and technology in the manufacture of storage rack roll forming machines to ensure the high precision and durability of each component, and strictly controls the details during the production process.

3. Assembly and testing

After all parts are assembled into a complete production line, KINGREAL will conduct comprehensive functional and performance tests to ensure the reliability of the supermarket storage rack machine in actual operation.

4. ISO9000 certification

KINGREAL has passed ISO9000 certification and has ISO9000 quality system management capabilities, ensuring KINGREAL's high standards and continuous improvement in all aspects of production, testing and service.