Warehouse Shelf Upright Rack Making Machine

KINGREAL is a professional roll forming machine supplier in China, can provide Warehouse Shelf Upright Rack Making Machine according to your need. Send us the parameters or product drawings, we will design the program for you and send the latest offer.

- KINGREAL

- China

- 60 Days

- 9999

- Information

- Download

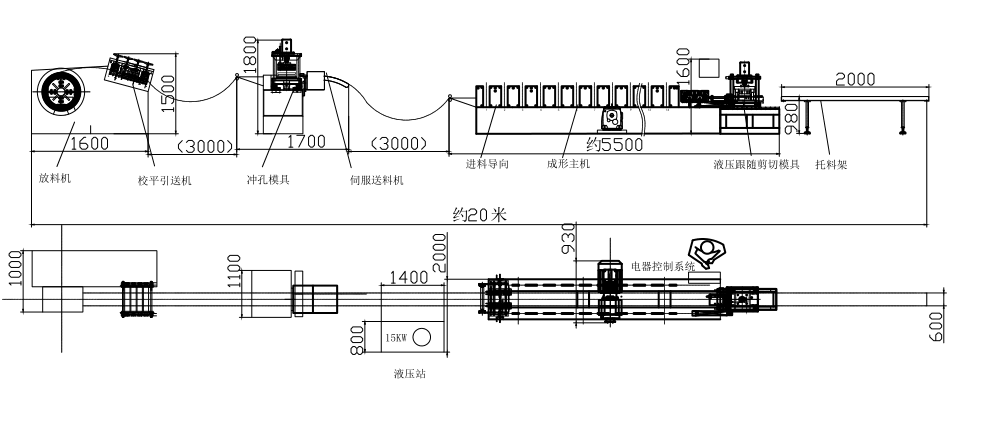

Description of Storage Rack Post Roll Forming Machine

KINGREAL Storage Rack Roll Forming Machine is used to manufacture metal rack upright. It usually consists of frame, feeding system, forming system, punching machine and other equipment.

Shelf Column Roll Forming Machine can feed the metal sheet into the forming system through the feeding system, and then get the finished products of shelf column after processing and forming. The shelf column roll forming machine has the characteristics of high efficiency, precision and stability, which can greatly improve the production efficiency and quality of shelf column.

Main Processes of Storage Rack Roll Forming Machine

Hydraulic Decoiler -- Leveling -- Hydraulic Punching Press -- Main Roll Forming -- Cutting -- Output

Technical Specs Of Storage Rack Shelf Machine

125 Tons Punching Press KINGREAL equipped a 125 tons high capacity hydraulic punching press in the Rack Upright Making Machine. The body of the punching press is refined from high-strength steel, which can withstand high-speed and continuous stamping operations. KINGREAL also equip the punching press with a hydraulic system, which facilitates the realization of overload protection. |  |

Main Roll Forming Machine The forming roller of the main forming machine is made of Cr12MoV and is made through vacuum heat treatment. Vacuum heat treatment can quickly reduce the hydrogen content in metals and alloys, thereby eliminating hydrogen embrittlement and improving the plasticity, toughness and fatigue strength of the material. |

|

| Cutting Station The cutting station equipped with the shelf upright rack machine adopts a high-precision saw blade shearing design to ensure excellent performance during the cutting process. The saw blade is made of high-quality materials with excellent hardness and wear resistance. It can remain sharp during long-term operation and reduce the frequency of replacement. This high durability feature not only extends the service life of the saw blade, but also improves production efficiency. In addition, the upright rack after cutting has extremely high precision, smooth edges and no burrs, ensuring that the appearance and functionality of the product meet industry standards. This precision shearing system greatly improves the consistency of the shelf upright rack and meets customers' demand for high-quality products. |  |

Advantages Of Upright Rack Machine

Multiple sizes of upright rack

There is a choice of automatic or manual size conversion. The automatic size change function can significantly reduce the production line change time and improve production efficiency. The manual size change function allows operators to make manual adjustments under special circumstances to ensure a smooth production process. This design allows companies to have higher flexibility in the production process and quickly respond to changes in customer orders.

High-quality cutting system

The cutting station is equipped with precision shear blades to ensure the cutting accuracy and surface finish of the finished product, improving the overall quality of the product. In addition, the high wear resistance and long life of the blades reduce the frequency of replacement and reduce production costs.

Convenient installation and maintenance

KINGREAL storage rack shelf machine design takes into account the user experience, and the installation process is simple and intuitive. The shelf upright rack machine can be installed according to the instructions or guidance videos. In addition, the daily maintenance cost is low, and the structural design of the upright rack machine makes maintenance operations convenient and reduces downtime.

Complete Shelving System Production Solution

Shelving Panel Roll Forming Machine also can be provided by KINGREAL, combination with Shelf Column Roll Forming Machine can be a complete shelving production system. It is benefit for maintaining production consistency of shelf panel and shelf column.

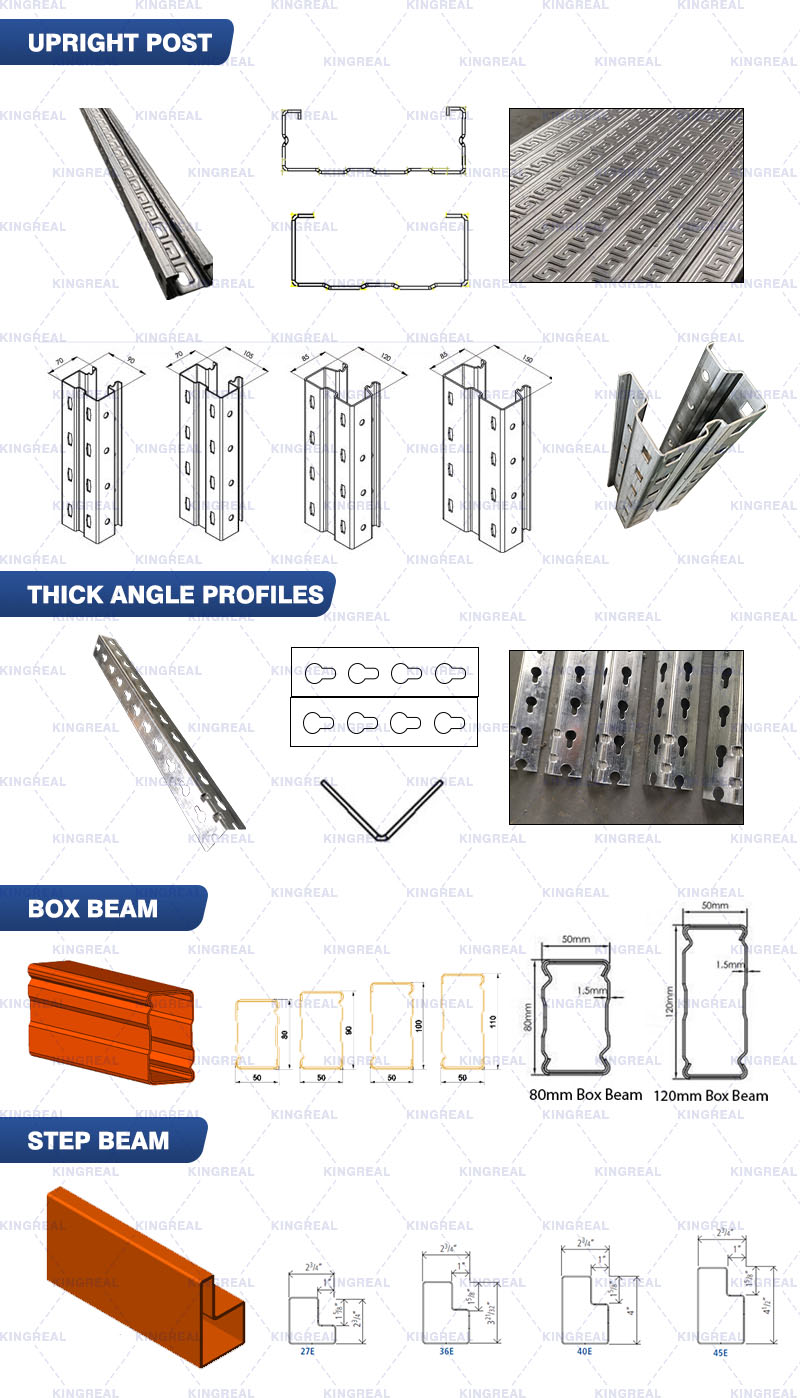

Diverse Rack Upright Production Solution

KINGREAL is good at providing customers with a variety of rack upright production solutions. KINGREAL's machines are capable of producing upright posts, thick angle profiles, box beams, and step beams of different sizes. You are welcome to inform KINGREAL engineers of your drawings and specific production requirements. KINGREAL engineers will provide customized rack upright roll forming machine manufacturing solutions after full communication with you.

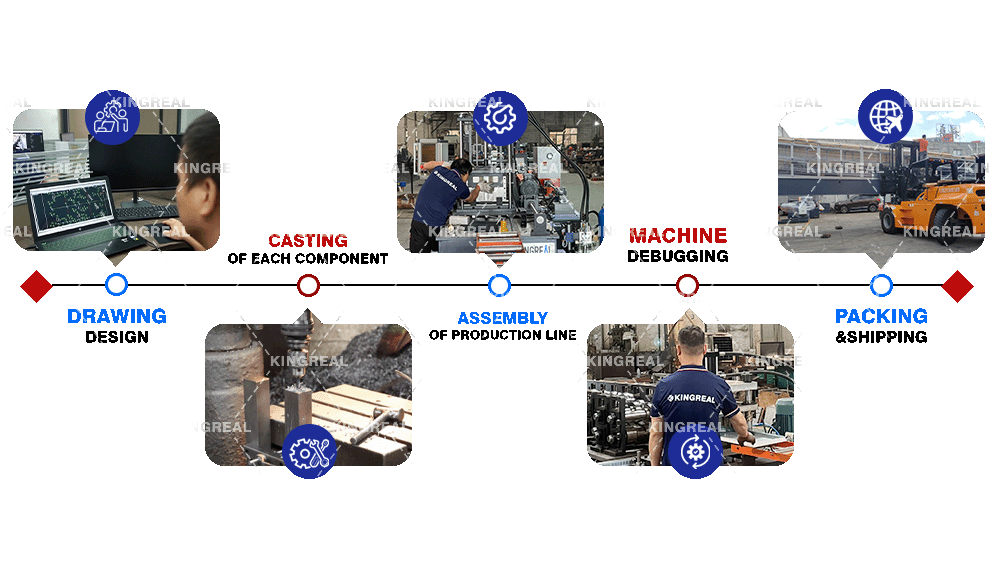

Technology Support

As a professional manufacturer of roll forming machine in China, KINGREAL has been in design - production - installation - after-sales for more than 20 years. KINGREAL is able to customize production solutions according to customer‘s drawings and specific parameter requirements. After you ordered, KINGREAL technical team will test the machine in an effort to insure every mechanical and electrical parts are in perfect condition.

KINGREAL in Diverse Exhibitions

KINGREAL actively participates in exhibitions around the country to show customers advanced rack upright roll forming machines and other roll forming machines and professional technologies. With rich industry knowledge and in-depth understanding of the machines, KINGREAL's team can quickly answer customers' questions and provide professional advice at the exhibition. This efficient communication enables the company to establish good initial contacts with customers from different countries, successfully exchange contact information, and lay the foundation for subsequent in-depth exchanges.

In addition, KINGREAL has won wide acclaim from customers for its high-quality machines and meticulous after-sales service. Customers generally reflect that KINGREAL's equipment is not only stable in performance and long in service life, but also can effectively meet production needs. KINGREAL is committed to continuously optimizing products and services to ensure that customers can enjoy a high-quality experience at every stage.